Another plasma component...

- Dee436

- Offline

- Premium Member

-

- Posts: 91

- Thank you received: 13

Thank you so much for this,

I am in UK so have just seen the configs you posted. I am planning to use gmocappy anyway so not too concerned regarding the axis stuff.

I learn best by example so I will get a lot of understanding about Linuxcnc from seeing how you added the parts I did not understand.

I will get my plasmac branch updated, check through the files in more detail and try them out on my machine

Thanks again

Darren

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11655

- Thank you received: 3924

I think you are saying plasmac has an output that says " I am probing now"

This output probably closes a relay that allows the ohmic sensing to operate only when probing.

Then there is a probing input. which is triggered when the torch touches the work piece.

Is that how it works?

I've made some progress with building this but will talk about that on my build thread to save cluttering this up

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

There are a few pins used here:

- ohmic-max-attempts - input - maximum ohmic probe attempts before fallback to float switch

- ohmic-probe - input - ohmic probe input

- ohmic-test - input - when on attempt a single ohmic probe (shorted torch test)

- ohmic-enable - output - on only while probing

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

I may not get to live cutting today but here is what I found so far.

I think that the Torch Enable button should be in the disabled state on startup of LinuxCNC. I know this is personal preference sort of thing.

The torch did a dry run with the torch disabled.

The torch is still moving to Z Max after traversing at Safe Z height before probing from Z Max. Think is that the probing sequence should be:

Move from Z max or safe Z to Probe Height at G0 speed. Slow to probe speed and probe. At end of cut torch should return to Safe Z or Z Max as appropriate (I think this works correctly).

I am not sure now what the Probe Height setting is supposed to be. If it is the height that the torch slows to probe speed then the current range of values is too small for an imperial machine. I think the default value should be about .75" and the setting range should be .25" to 1.25".

When probing and the float switch actuates first plasmac treated this as an ohmic probe failure. So on my setup every probe try using the float switch resulted in 5 tries before moving to pierce height. I think if the float switch actuates first it should be the signal to use the float switch height for the probing.

I will try to get to making a video and doing live cutting today but it doesn't look good.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11655

- Thank you received: 3924

But if John says its required, go with him as he probably cuts more in one day than what I've cut since I built my table.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Will do, if this is a problem for others I will make it an ini file setting.islander261 wrote:

I think that the Torch Enable button should be in the disabled state on startup of LinuxCNC. I know this is personal preference sort of thing.

Yay!!!The torch did a dry run with the torch disabled.

I will check this out later today.The torch is still moving to Z Max after traversing at Safe Z height before probing from Z Max. Think is that the probing sequence should be:

Move from Z max or safe Z to Probe Height at G0 speed. Slow to probe speed and probe. At end of cut torch should return to Safe Z or Z Max as appropriate (I think this works correctly).

Height above zero point (top of slats?) Z moves at setup-speed (in config tab) to this height then moves at probe speed.I am not sure now what the Probe Height setting is supposed to be. If it is the height that the torch slows to probe speed then the current range of values is too small for an imperial machine. I think the default value should be about .75" and the setting range should be .25" to 1.25".

If ohmic-max-attempts is set to zero then it should use the first signal as you described, I will check later.When probing and the float switch actuates first plasmac treated this as an ohmic probe failure. So on my setup every probe try using the float switch resulted in 5 tries before moving to pierce height. I think if the float switch actuates first it should be the signal to use the float switch height for the probing.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

- add torch enable/disable.

- remove dry-run (to do a dry run press run while torch is disabled).

- GUI's start with torch disabled.

- minor fixes to Axis native button press events.

A question...

At the moment if there is Z axis motion before beginning a job then if the Z axis is lower than safe height the offsets get confused and this can lead to errors and gcode unable to be run. Basically you need to re home the machine.

A fix for this is to reset the offsets at the end. This will cause the Z axis to move to the actual starting height rather than Z max.

I feel this is the lesser of two evils. If someone has moved their Z axis they probably have a good reason...

I would like to hear what others think.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I broke safe height before probing a little while ago, it is fixed and an update pushed...

Another question:

Instead of specifying probe-height as the height above the slats, would it be reasonable to specify probe-height as the height above the top of the stock. This would mean the very first probe would be slow as it would run at probe-speed from wherever the start Z is. After this all subsequent probes would be from probe-height above the top of stock as measured from the last cut.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

I had always thought of automatic fallback to the float switch when it is activated first but the setting the retries solution should be workable as you usually know when you want to use the float switch VS ohmic.

I still had a large number of false shorted probing failures. Every time I checked with the test button the torch was clear. I must admit that with my Gmoccapy configuration I always probed very slowly down and 1/16 the probe speed up. I have my debounce set to 5 times so that may be why I didn't get many false alarms.

I run my table like a milling machine and not like some Mach 3 configuration from PS. I home the machine on startup to establish the machine coordinates. The machine Z zero is at the top (away from bed) of the Z motion. Then I place the material on the table and set the work piece zero by jogging the torch to the correct location (I have a couple of laser line generators to make a crude set of cross hairs). I then set the G54 X zero and Y zero offsets to that location. So at this point my machine knows where it is and the offsets to the work piece. When I probe the material I set the work piece Z zero to the top surface of the material using a G92 Z0 (one could also use a known offset). Then I start cutting. At the end of the Gcode file I always do a G92.1 to clear the G92 offsets. So when cutting my DRO always shows the height above the material the torch is. Oh, I do have a "permanent" G54 Z offset so that the work piece Z is the actual approximate height above the slats.

Here are a couple of videos that show the probing I described previously.

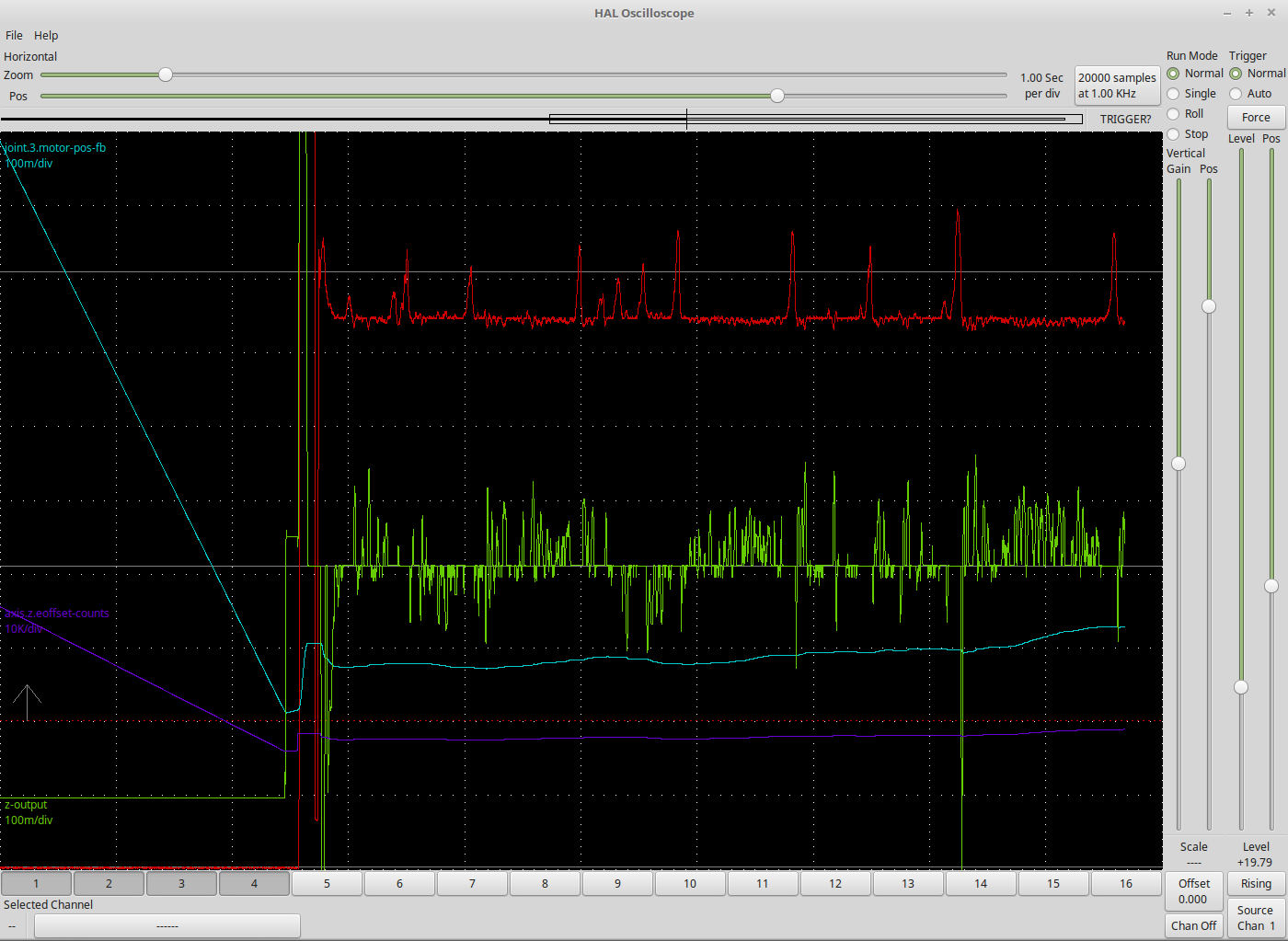

I also grabbed a halscope of part of the outside cut on one of the crabs. The big voltage spikes are the slowdowns for the sharp corners. Look at how nice and steady the voltage is in between. One thing I found when working out the corner lock on my system is that one needs to keep the height hold active until the speed gets back to 99% of the target speed. !00% always caused problems over being reliable. What happens is the arc voltage lags the torch speed a bit so if you restart THC at the same point you held the height the voltage is still way high and the torch dives.

For those that haven't done much of this it is a good plot of a real (non straight line) cut.

John

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

That probing is just plain wrong, I will try to emulate that on my test rig.

Cheers, Phill.

Please Log in or Create an account to join the conversation.