Another plasma component...

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

arc_voltage_scale = (28778.125 - 3659.375) / 300 = 83.73

so then I think that means the

arc_voltage_in = hm2_7i76e.0.encoder.00.velocity

Is that what you were thinking?

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Did I forget to document that?

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

I recall that you use a custom component to do your encoder.velocity to displayed arc voltage conversion. If this is still the case you just need to input a scale of 1 and an offset of zero. I actually use the scale hal component to scale mine so I just use a config scale value of 1 and offset of 0. Your making this way harder than it needs to be for what you have gotten working before. You want to use plasmac mode 1 for THC. Look at the examples I posted for others. At this stage of the game with frequent updates I am putting all my machine specific .hal connections in my machine.hal file (well most of them, the pendant introduces it's own problems).

Phill

Ok, I am not going crazy looking for a configuration problem. My machine Z zero is at the top of the Z axis travel like a milling machine, the work piece Z zero (G54 Z) is the top of the work piece. I need a Safe Z that is about 1" above the work piece to miss tip ups ( and a probe distance of up to 1.25" for really thick plate). In my mind you always want the machine to reference against a known machine location (home switch or other) and not against a variable part like slats (not a true unmovable surface like a milling machine table). I have no idea how to tram a torch against a floppy set of slats. I am well aware of the legacy work around done by all the plasma table people that used Mach 3 and couldn't properly home the Z and find a work piece surface by probing. There is no reason to do this with LinuxCNC, if you use Gcode we can use G38.x probing or directly set the G54 Z offset from a probing part of a .hal component. So my .ini Zmax value is .25" and my .ini Z min value is -3.125, of course these are in machine (G53) values as all soft limits are.

I actually do use XYYZ layout for my configuration.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

islander261 wrote:

Ok, I am not going crazy looking for a configuration problem. My machine Z zero is at the top of the Z axis travel like a milling machine, the work piece Z zero (G54 Z) is the top of the work piece.

.

So my .ini Zmax value is .25" and my .ini Z min value is -3.125, of course these are in machine (G53) values as all soft limits are.

OK, that explains a lot, I have my milling machine Z zero at the table so my Z max is top of Z travel....

I have done all this work using the same setup so it looks like I need to change a few things to suit both setups.

I don't measure anything from the slats, I just think that should be the bottom soft limit or thereabouts.

I am happy for you to find configuration problems so long as it doesn't put you off doing more testing.

I will switch my test rig coordinates around and sort it out...

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

The on screen scaling does not work because of enforced upper and lower limits in the config screen as I can't enter an offset of 3659.375 (0-100 enforced)

Also the maths in my earlier post says the frequency counts per volt is 83.73 and you have to input the reciprocal of this which is 0.011943151 which is not logical. So I would recommend that the maths be changed to do the reciprocal stuff internally and also remove the enforced range on the scale. If that was the case I think it would work well with some explanation in the docs.

So for now I'll revert to my scalethcad component. It is now quite sophisticated with averaging and stuff built in but the doc side of it needs cleaning up.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

You can comment it out in the ini file

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

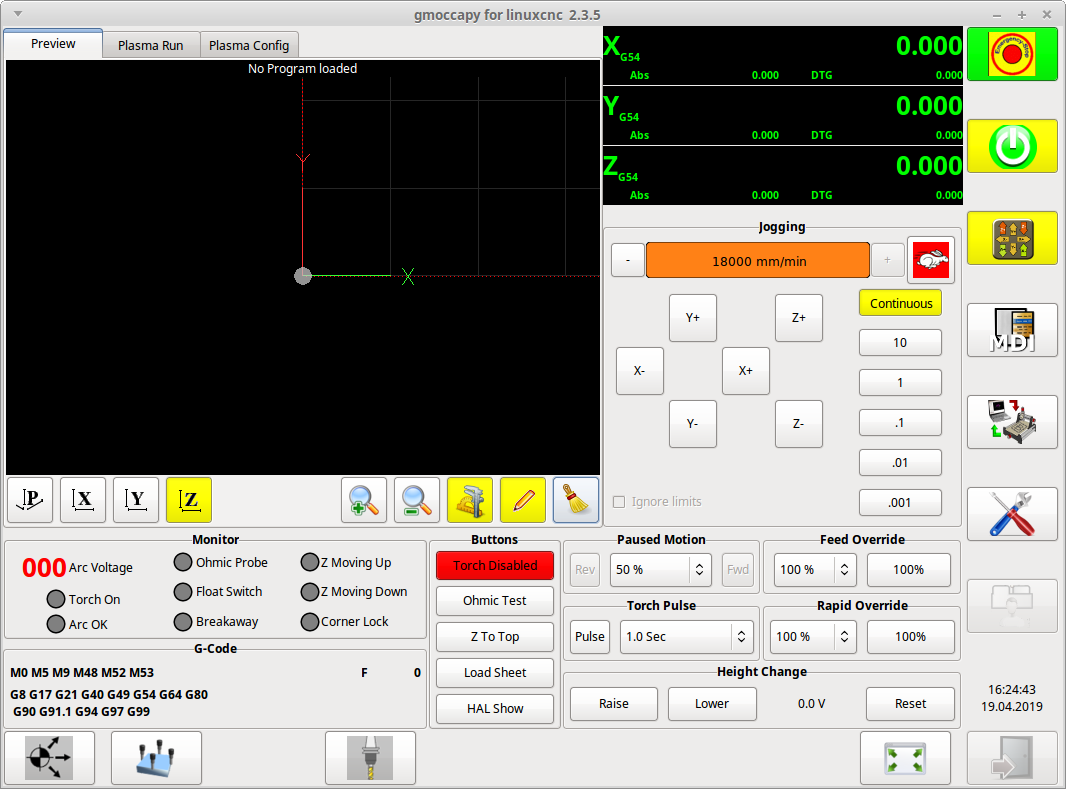

I pulsed the torch and flames spewed forth!

Reverted to my scaling component

I just have to work out why my pendant is not going and why my orange warning light is not coming on but thats not a plasmac issue.

Also found a fault on my Z axis homing to a shared home/limit switch as it was missing HOME_IGNORE_LIMITS somehow. not sure how I lost that.

I still don't understand everything yet and have to build some material tables.

What do the Ohmic Test, Z to top and Load sheet do?

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Ohmic Test - John uses this to test for a shorted torch, it turns on the ohmic-enable outputWhat do the Ohmic Test, Z to top and Load sheet do?

Z To Top - moves Z to the top soft limit

Load Sheet - moves all axes to a place that is good for loading a sheet of material

All these are programmable in the ini file.

Cheers, Phill.

Please Log in or Create an account to join the conversation.