Another plasma component...

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

16 Apr 2019 06:11 #130967

by JTknives

Replied by JTknives on topic Another plasma component...

Thank you so much for all your help. i do have a working ini and hal file but it was just put together to connect to the 7i76ed and test my stepper motors. I have not connected the thcad or any of my limit switches yet. still muddling my way throught that.

Please Log in or Create an account to join the conversation.

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

16 Apr 2019 16:02 - 16 Apr 2019 16:17 #130984

by Dee436

Replied by Dee436 on topic Another plasma component...

I thought I should move to posting on this thread rather than the THCAD-10 thread I originally started on, as I am now working with the Plasmac component.

I had got to the position of having a run in place Plasmac side by side the existing 2.7 installation that is in use on my table, but lacks THC functionality. The plasmac sims were available and usable.

I have eventually managed to get a couple of hours spare to look at moving this to production use on my table and believe I have managed to get the .ini sorted out. unfortunately with the hal I am again stuck due to my lack of knowledge on linuxcnc.

My setup is mesa 5i25 - 7i76 - thad 10.

I am unsure just what I need to add to the plasmac.hal file to get things working, I did start to add things to the mode 1 section but don't think what I have done is correct. I have attached my plasma.hal and custom hal as well as the plasmac.hal any help would be appreciated.

Darren

I had got to the position of having a run in place Plasmac side by side the existing 2.7 installation that is in use on my table, but lacks THC functionality. The plasmac sims were available and usable.

I have eventually managed to get a couple of hours spare to look at moving this to production use on my table and believe I have managed to get the .ini sorted out. unfortunately with the hal I am again stuck due to my lack of knowledge on linuxcnc.

My setup is mesa 5i25 - 7i76 - thad 10.

I am unsure just what I need to add to the plasmac.hal file to get things working, I did start to add things to the mode 1 section but don't think what I have done is correct. I have attached my plasma.hal and custom hal as well as the plasmac.hal any help would be appreciated.

Darren

Last edit: 16 Apr 2019 16:17 by Dee436.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

16 Apr 2019 17:13 #130988

by islander261

Replied by islander261 on topic Another plasma component...

Dee463

Please post the working .hal files and .ini files from your working configuration if the ones you posted are not. Are you using a float switch for IHS?

I can see that you are falling victim to the usual 2.7 to 2.8 gotchas concerning multiple spindle support in 2.8. Look in the docs for the master branch and this will all become clear as mud.

I will fix you up with close to working config after work today.

John

Please post the working .hal files and .ini files from your working configuration if the ones you posted are not. Are you using a float switch for IHS?

I can see that you are falling victim to the usual 2.7 to 2.8 gotchas concerning multiple spindle support in 2.8. Look in the docs for the master branch and this will all become clear as mud.

I will fix you up with close to working config after work today.

John

Please Log in or Create an account to join the conversation.

- Dee436

- Offline

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 13

16 Apr 2019 18:25 - 16 Apr 2019 18:30 #130995

by Dee436

Replied by Dee436 on topic Another plasma component...

Hi John

A close to working config would be great. I get such small amount of time at the moment that I am struggling with this. Unless I inadvertently uploaded the wrong files earlier, they are the ones I have that are working. I have just pulled then from the machine again to be sure and they are attached although they got re-named somehow when I uploaded them. You will recognise the content of the custom hal as its your code

The table I have was built by me and is a pretty standard gantry type plasma, where it is a little different is that I only have one motor on the gantry (Y axis). I basically have a rack on each side of the machine connected to belt reductions gearboxes which are joined by a jackshaft so it is xyz rather than xyyz.

I also have;

Ohmic sensor as yet unconnected.

Torch breakaway switch connected in series with the E-stop as I could not work out how to connect it separately in LinuxCNC.

IHS is via a floating switch and uses the probe in, and a G-code routine.

I am using the table and have cut lots of parts, homing, probing, and everything else is working fine, I just have no THC, hence the move to plasmac.

Darren

A close to working config would be great. I get such small amount of time at the moment that I am struggling with this. Unless I inadvertently uploaded the wrong files earlier, they are the ones I have that are working. I have just pulled then from the machine again to be sure and they are attached although they got re-named somehow when I uploaded them. You will recognise the content of the custom hal as its your code

The table I have was built by me and is a pretty standard gantry type plasma, where it is a little different is that I only have one motor on the gantry (Y axis). I basically have a rack on each side of the machine connected to belt reductions gearboxes which are joined by a jackshaft so it is xyz rather than xyyz.

I also have;

Ohmic sensor as yet unconnected.

Torch breakaway switch connected in series with the E-stop as I could not work out how to connect it separately in LinuxCNC.

IHS is via a floating switch and uses the probe in, and a G-code routine.

I am using the table and have cut lots of parts, homing, probing, and everything else is working fine, I just have no THC, hence the move to plasmac.

Darren

Last edit: 16 Apr 2019 18:30 by Dee436.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

16 Apr 2019 20:37 #131001

by JTknives

Replied by JTknives on topic Another plasma component...

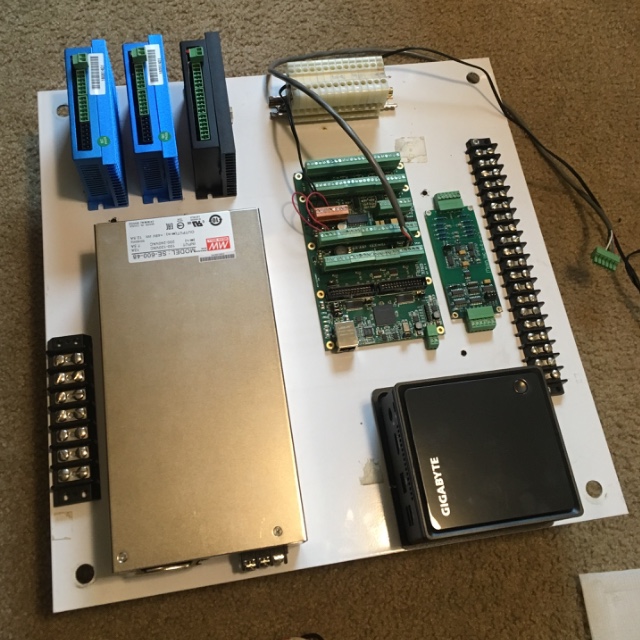

Attachments:

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

16 Apr 2019 23:50 - 16 Apr 2019 23:55 #131019

by islander261

Replied by islander261 on topic Another plasma component...

Darren

Please find attached machine.hal and darrens_plasmac.ini for your system. They should be close but carefully check all motion and torch controls. I have never used AXIS so this is a bit of an unknown to me. Always start your new configuration from a (new) terminal after setting the RIP environment so you can get the errors reported. We will need those cut and pasted into <code> </code> sections in your forum posts to help you.

First make sure your plasmac branch is up to date. There were updates posted this weekend.

You will need to fix the Z to Top and Load Sheet buttons for your machine in darrens_plasmac.ini before using them.

Check your Z limits in darrens_plasmac.ini

Only use an unmolested plasmac.hal file, I have put all the connections to your machine in machine.hal.

You can connect your break away switch to it's own input every thing is waiting for your hardware pin in machine.hal. Plasmac will take care of a break away.

You can connect ohmic probe to it's own input every thing is waiting for your hardware pin in machine.hal. Plasmac will take care of the ohmic probe if used.

Phill

Please give these a sanity check as I have never used Axis or a metric machine.

John

Please find attached machine.hal and darrens_plasmac.ini for your system. They should be close but carefully check all motion and torch controls. I have never used AXIS so this is a bit of an unknown to me. Always start your new configuration from a (new) terminal after setting the RIP environment so you can get the errors reported. We will need those cut and pasted into <code> </code> sections in your forum posts to help you.

First make sure your plasmac branch is up to date. There were updates posted this weekend.

You will need to fix the Z to Top and Load Sheet buttons for your machine in darrens_plasmac.ini before using them.

Check your Z limits in darrens_plasmac.ini

Only use an unmolested plasmac.hal file, I have put all the connections to your machine in machine.hal.

You can connect your break away switch to it's own input every thing is waiting for your hardware pin in machine.hal. Plasmac will take care of a break away.

You can connect ohmic probe to it's own input every thing is waiting for your hardware pin in machine.hal. Plasmac will take care of the ohmic probe if used.

Phill

Please give these a sanity check as I have never used Axis or a metric machine.

John

Last edit: 16 Apr 2019 23:55 by islander261.

The following user(s) said Thank You: phillc54, Dee436

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Apr 2019 00:17 #131022

by phillc54

Replied by phillc54 on topic Another plasma component...

John,

Thanks for your time in helping out with this.

A couple of things in the ini file.

missing:

change to:

When I get some time I really should document how to set up a working config for new users...

Cheers, Phill.

Thanks for your time in helping out with this.

A couple of things in the ini file.

missing:

[KINS]

KINEMATICS = trivkins coordinates=xyz

JOINTS = 3change to:

[AXIS_2]

MAX_VELOCITY = 100

MAX_ACCELERATION = 750When I get some time I really should document how to set up a working config for new users...

Cheers, Phill.

The following user(s) said Thank You: Dee436

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

17 Apr 2019 00:58 - 17 Apr 2019 01:10 #131026

by islander261

Replied by islander261 on topic Another plasma component...

Phill

Thank you, I was sure that I'd missed something because I don't have the hardware to test.

I believe that your branch should be very attractive to newbie plasma cutters because of the simplified PP required and the fact that it will work with Gcodetools with little modification. A newbie setup guide will be helpful but a lot of work given the pace of evolution in your branch right now. Actually all the instructions needed are on the forum with a little looking, I fully realize that searching a forum for information you don't even know you need is pretty daunting.

John

Thank you, I was sure that I'd missed something because I don't have the hardware to test.

I believe that your branch should be very attractive to newbie plasma cutters because of the simplified PP required and the fact that it will work with Gcodetools with little modification. A newbie setup guide will be helpful but a lot of work given the pace of evolution in your branch right now. Actually all the instructions needed are on the forum with a little looking, I fully realize that searching a forum for information you don't even know you need is pretty daunting.

John

Last edit: 17 Apr 2019 01:10 by islander261.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Apr 2019 01:39 #131030

by phillc54

Replied by phillc54 on topic Another plasma component...

John,

I have done a torch-enable in the component and removed dry-run.

I have also done this for Gmoccapy, it reduces the user buttons to four from the original five.

I am hoping you will be able to test it and see if I am on the right track before I change the other GUI's and push to the branch.

The changes are:

- New plasmac.comp which you would need to compile as before.

- New Glade and Python files for the button panel to be copied to your config

- Changes to make to your ini file for the buttons

Cheers, Phill.

I have done a torch-enable in the component and removed dry-run.

I have also done this for Gmoccapy, it reduces the user buttons to four from the original five.

I am hoping you will be able to test it and see if I am on the right track before I change the other GUI's and push to the branch.

The changes are:

- New plasmac.comp which you would need to compile as before.

- New Glade and Python files for the button panel to be copied to your config

- Changes to make to your ini file for the buttons

Cheers, Phill.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

17 Apr 2019 02:40 #131032

by islander261

Replied by islander261 on topic Another plasma component...

Phill

Thank you, I will try and get some testing done tomorrow. I finished my semi annual slat repair and clean out this morning so the table is ready for use now. I am sure that I can get a sheet parts CAMed in the morning.

John

Thank you, I will try and get some testing done tomorrow. I finished my semi annual slat repair and clean out this morning so the table is ready for use now. I am sure that I can get a sheet parts CAMed in the morning.

John

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.308 seconds