Center Spot Sheetcam Post

- docwelch

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 25

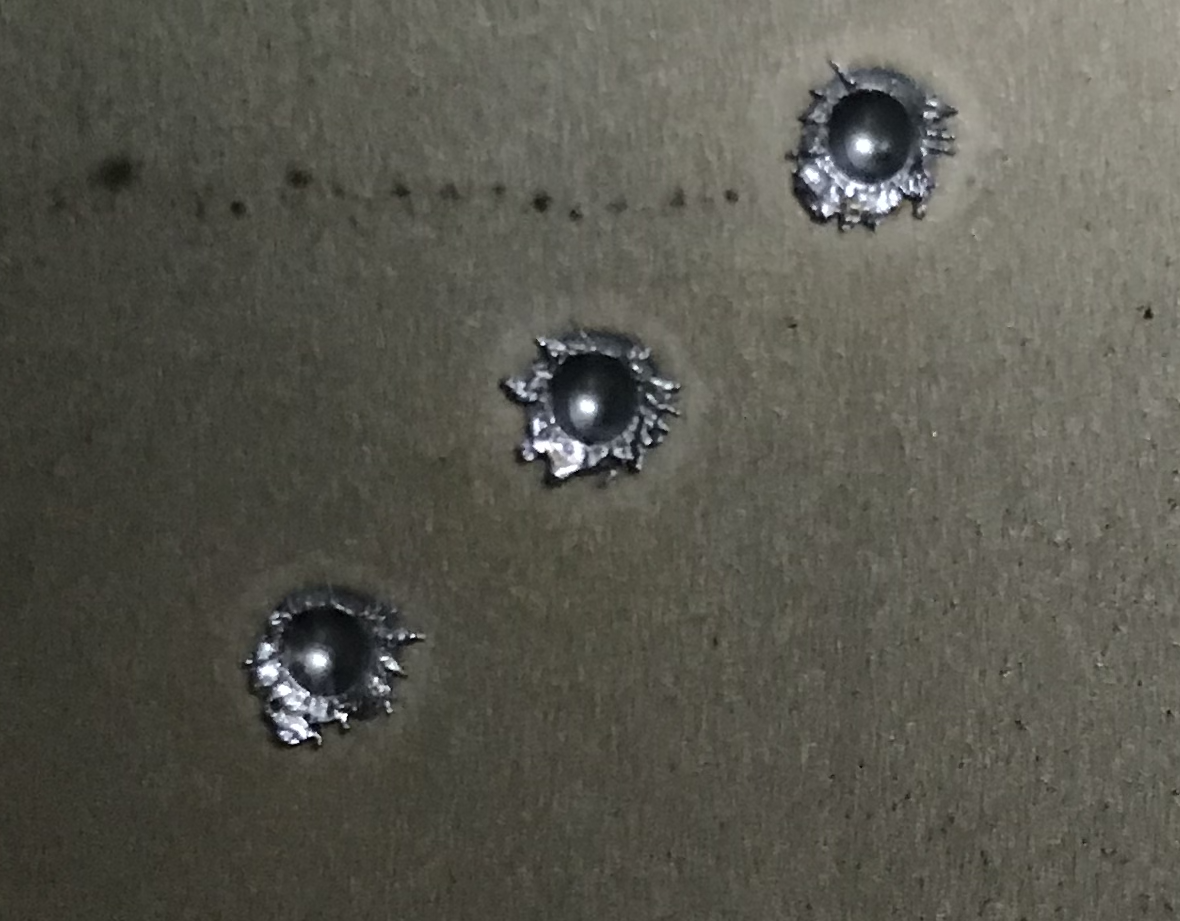

The following pictures are of 18g CR steel, fine cut consumables, cutting mode. The dimples are at (0.25", 0.25"), (0.5",0.5"), and (0.75",0.75") to give you some idea of the size:

45a at a pierce height of 0.15" - it did not completely pierce the material but you can feel the dimple on the back side.

10a at pierce height of 0.15" - makes a nice dimple

10a at a pierce height of 0.25" - makes a nice dimple but more shallow. I did this as the Hypertherm cut charts for dimpling use this height.

So, a great big thanks to Phill and good news for those with Hypertherm equipment - it can work without changing consumables and modes and current.

Steven

Attachments:

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

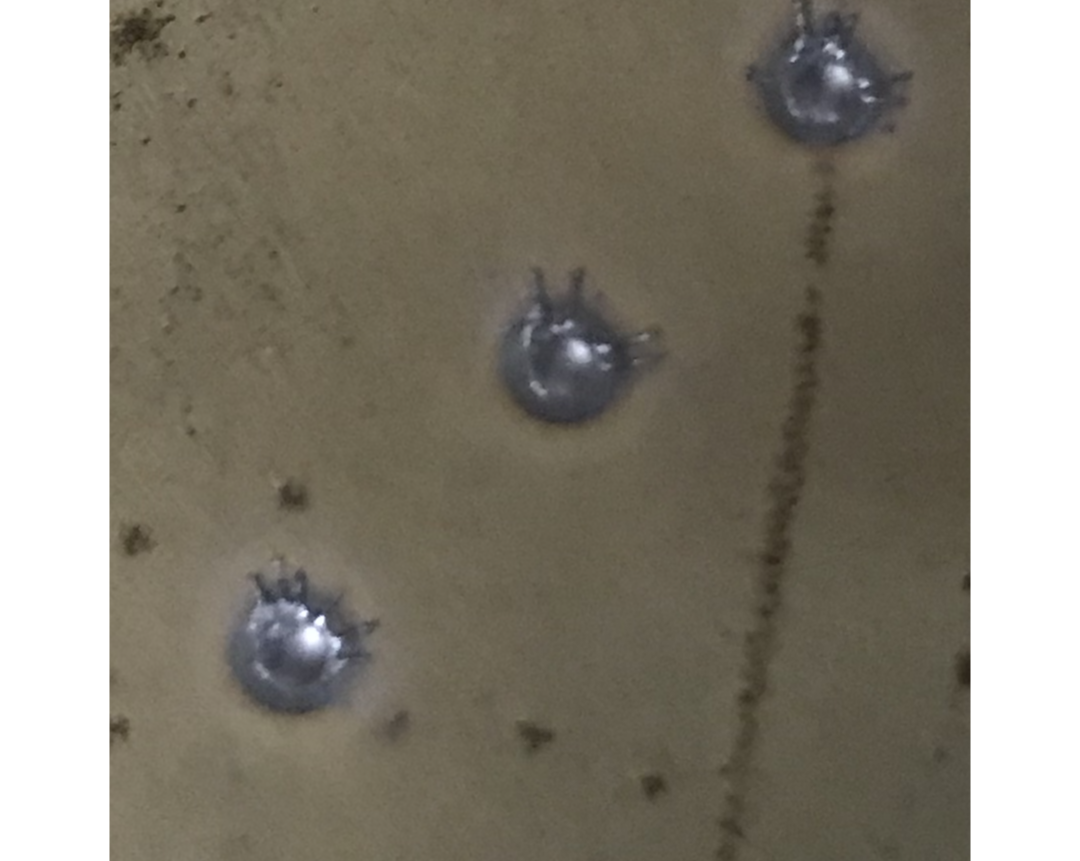

I did a few tests with my TD A-60 and did manage to make a couple of marks. The power supply was set to 45A and the torch height was .090", the correct height for piercing with the Finecut consumables used. I tested using the torch pulse function at pulse widths from .1s to .9s. The test material was 14ga (2mm) hot rolled steel. Sorry I haven't looked into using the center punch post or PlasmaC functions.

Some top level observations:

1. The power supply didn't produce any arc voltage until the plasmac.torch-on pulse width was .6s or greater.

2. The arc voltage starts to decay rapidly 7ms to 10ms after plasmac.torch-on goes low.

3. The power supply OK to Move signal (plasmac.arc-ok-in) is delayed from the apparent arc transfer by about 15ms.

4. At approximately 2.5ms of arc time past OK to Move (plasmac.arc-ok-in) going true the center punch mark produced an approximately .039" (1mm) deep mark. I had no way to finely control this time during the test so the next longest increment punched all the way through the material.

The pulse times from right to left are .7s, .8s, .9s and .7s. While in the photo it appears that both .7s dimples went all the way through the material I wasn't able to push a 30ga wire through either hole. When I examined the back side of the material it confirmed that the .7s pulses (about 2.5ms arc time after Ok to Move went true) did not penetrate the material completely.

I have attached Halscope screen shots for pulse times of .6s to .9s.

6_10... 1412-16-19.png is .6s pulse width

7_10...1412-22-48.png is .7s pulse width, far right dimple in photo

8_10...1412-26-50.png is .8s pulse width, second from right in photo

9_10...1412-30-10.png is .9s pulse width, second from left in photo

7_10-2...1412-38-32.png is .7s pulse width, far left in photo

The results for using a TD torch or using a HT power supply will be different.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11646

- Thank you received: 3919

Rod

I am sure that without using external hardware (as Keith does) or fast arc voltage monitoring the path to success will be different for HT and TD power supplies. My TD A-60 requires a torch fire signal at least .7s long to get the torch to fire even briefly when using the torch fire button on Plasmac (maybe some knowledgeable TD engineer can weigh in on this) . The OK to Move signal is also very slow, I typically use zero pierce delay up to 10ga steel. I believe that stopping the arc is fairly quick once the torch fire signal is removed. This is sounding like it is time for a little halscope investigation.

John

Thanks John, the intent is to turn on the torch relay, wait until an arc starts, then turn off the arc after the delay expires. That way the lag in turning on is eliminated.

I too thought the TD arcOK was fairly slow.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

What is the first arc voltage pulse, is that HF start?

Rod,

The experimental component I posted will do that, for values over 300 the delay is (300 minus value)mS after Arc OK detected.

Edit: Or did you mean after any arc voltage is sensed?

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

We will need to find an ESAB or TD engineer for the real answer to that question. This power supply and torch are conventional blow back start the same as all the newer HT ones. I do know that the entire time that I have been using halscope to work on THC and corner hold problems my TD A-60 combined with my Franken torch the arc start has always looked like that. Maybe one of our deep pocketed friends with a HT power supply and torch can provide the group with some good arc start halscope plots for comparison.

I am thinking that an adjustable dead time and a rising voltage trip point should make for a good center punch divot. From my halscope plots I am seeing the OK to Move going true a short delay after the arc voltage reaches 40V. I have no way to know what the current set point is when the pilot arc is struck between the nozzle and the electrode, I do know that there is a good sized inductor in series with the output which will cause voltage to lead current in the circuit, the classic negative reactance like an arc lamp or welding machine once the arc starts. My current guess is that the arc voltage dip is when the arc actually transfers to the work piece and the rising voltage is when the constant current starts raising to the set point. Again my guess is that the OK to Move goes true when the arc current reaches the set point and the arc voltage is above some firmware set point. This is all a guess mind you, maybe a real plasma cutter engineer will speak up here.

John

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Thanks, that certainly is an interesting waveform and not one that I expected. I also didn't expect that much delay from the torch on signal until the arc voltage rise. It makes doing things with timing a bit hit and miss. It would definitely be interesting to see plots from other machines with the same conditions.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11646

- Thank you received: 3919

John,

What is the first arc voltage pulse, is that HF start?

John does not have a HF start machine.

Rod,

The experimental component I posted will do that, for values over 300 the delay is (300 minus value)mS after Arc OK detected.

Edit: Or did you mean after any arc voltage is sensed?

I meant after any voltage is sensed. Well actually, it will be after a voltage > 24.5 volts is sensed.

I have always centre spotted until an ArcOK comes on and then turn off. I did post a comparison of what I am able to do with a 220 ms delay from torch on and my old wait til arcOK method earlier in this thread. You don't need a different spindle to achieve this. Thats why I don't see any value in Phill's current experimental version.

Anyway here it is again.

So the rectangular parts show the front and back of 2mm mild steel spotted with the old wait til ArcOK method. (front on left, rear on right) I call this centre punch

The donut shows the 220 ms (front on left and rear on the right). Lets call it Centre spot.

You can see the exit hole on the 220ms centre spot is a lot smaller.

I still have not replicated what I observed when a bug in a component turned on the probe signal when the arc exceeded 24.5 volts. a probe signal disables motion immediately. The divot was just a tiny pinprick and a lot smaller than Doc's!

So what I'd like to see is another experimental version that turns on the torch, waits until the arc voltage exceeds 24.5 volts and then waits out the spot delay.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

The experimental version does do that.So what I'd like to see is another experimental version that turns on the torch, waits until the arc voltage exceeds 24.5 volts

So you don't want to wait for an Arc OK, you want the torch of nn mS after 24.5 Volts is reached. What does the 24.5V relate to?and then waits out the spot delay.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11646

- Thank you received: 3919

Correct, I wanted a smaller spot than what waiting for an ArcOK gave meSo you don't want to wait for an Arc OK, you want the torch of nn mS after 24.5 Volts is reached.

What does the 24.5V relate to?

There is an exceedingly complex multi variate regression equation that indicates this is the perfect number during the third lunar phase if you are located in the southern hemispehere below the 23rd parallel ......

Just kidding!!

24.5 volts is the full scale reading of my Hypersensing THCAD-5. I know the sensing power supply only outputs 24 volts so if it sees full scale, it can only be becasue the arc is on and it turns on a pin called arc-is-on. I was going to write something that started the delay based on my existing pin outside of plasmac. But it is much easier for plasmac to do it

I think this approach might need to ensure the movement/code before the M5 might need to include a dwell that exceeds the centre spot delay...

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11646

- Thank you received: 3919

Please Log in or Create an account to join the conversation.