PlasmaC torch starting problem (Solved with help from the famous three)

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

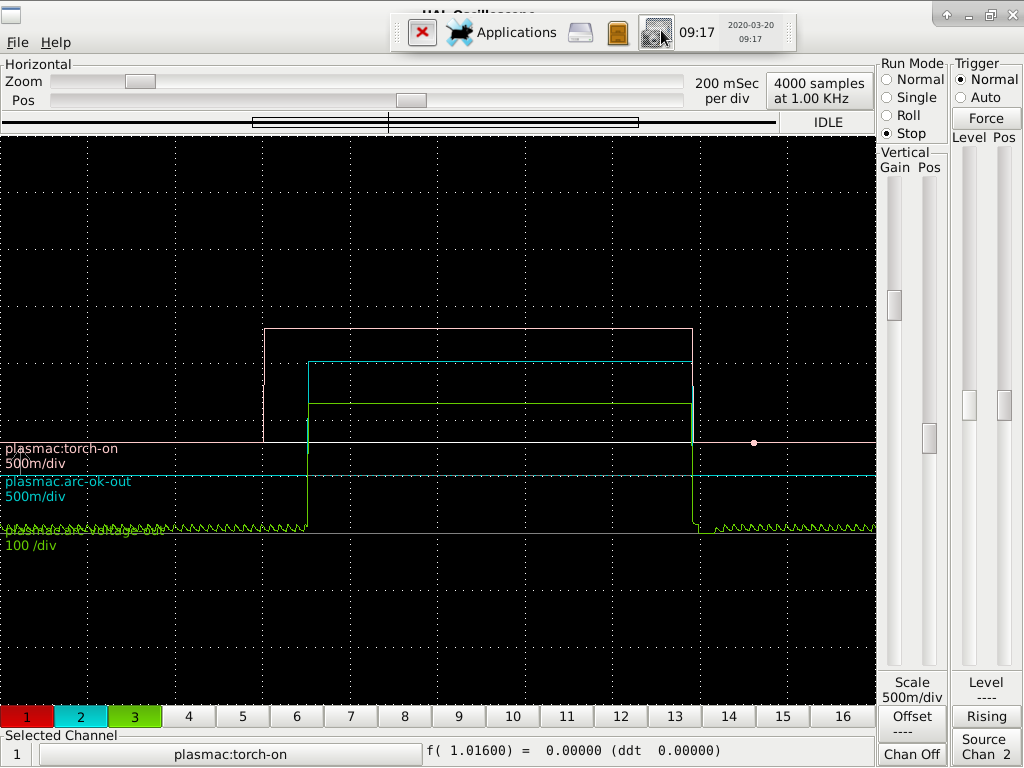

From all these plots it seems to me that PlasmaC is doing what it should do.

My take is that the fails are reading the pilot arc and not the cutting arc.

It is interesting that the first cut is always good and the waveforms do show that.

From the plot below it looks to me like the voltage drops off before the arc ok and the torch on which would be correct behaviour on PlasmaC's part but it would be nice to confirm that with say a 1ms or 5ms division.

Phil thanks.

which signal should I change to 1ms or 5ms or are you asking for the Hoz display set from 200ms to 5ms

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Yes, the horizontal thanks Clive so I can better see the timing of those signals.which signal should I change to 1ms or 5ms or are you asking for the Hoz display set from 200ms to 5ms

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11600

- Thank you received: 3900

www.pirate4x4.com/forum/shop-tools/95508...new-plasma-user.htmlA plasma torch with a pilot arc will fire a low power plasma arc in the air....this is a DC arc that goes from the torch electrode to the torch nozzle...and the force of the air blows the arc out through the nozzle (tip) orifice. The function? The pilot arc is designed to improve the ability of the plasma arc to transfer to the materials that needs to be cut......as the pilot arc approaches the plate, it burns through any surface issues (paint, rust, masking materials) and quickly transfers the arc....which electronically senses that current is now flowing through the work ground cable...and amperage ramps up (you will see the arc get more intense.

Older technology plasmas, and todays industrial mechanized plasma systems....use a pilot arc that is started with a high voltage, high frequency discharge between the nozzle and electrode to get the cutting air ionized. Newer technology air plasma systems use a "blowback start" ( a moving, spring loaded electrode in the torch) to ionize air, and are able to start a pilot arc without the use of high frequency.

I would look at your pierce height. Its possible with the air flowing the arc does not have sufficient force to transfer to the material. Its clear that there is no current sensed through the work ground cable. Was your plasma designed to accpet a pilot arc torch? IS the new torch compatible?

Looks like you could implement ohmic sensing with the right shield cup BTW.

Other than that, I think you are out of options

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11600

- Thank you received: 3900

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21131

- Thank you received: 7219

Now on these plots it is clearly visible what is going on, and i have to agree with Phill's conclusion that PlasmaC is working properly and doing everything it should do.

So to recap:

-Please do not lower the low voltage threshold ever again, it did cause us some head scratching, and some stray answers .....,

-PlasmaC is configured and working correctly,

-Wiring is all good,

-The noise is present while the inverter power stage is on, so nothing to worry about, most probably,

-Please oh please lower the pierce height and the cut height !

Pierce at 2mm and cut to 1mm, test and report back

P.S.

If you can find a reed relay, you can get the arcok signal that never fails and gives no false starts ever, but you do have to remove one of the thick cables on the plasma and replace it with a longer one, with 3 turns made out of it and the reed relay located inside those turns. Use a piece of old pen or similar to prevent the reed relay from braking, they usually are made out of thin glass.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

I must admit that I have only ever used a CNC enabled plasma power supply that generated it's own OK to Move (arc ok ) signal.

John

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

.

Yes, the horizontal thanks Clive so I can better see the timing of those signals.which signal should I change to 1ms or 5ms or are you asking for the Hoz display set from 200ms to 5ms

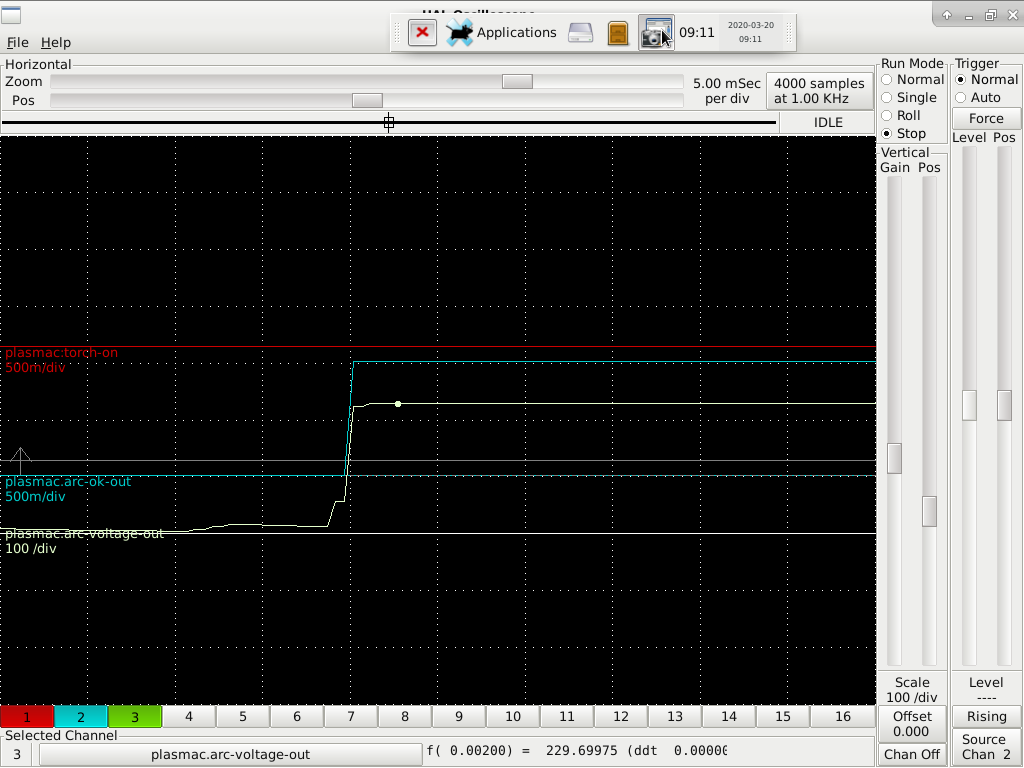

fail 5ms

.

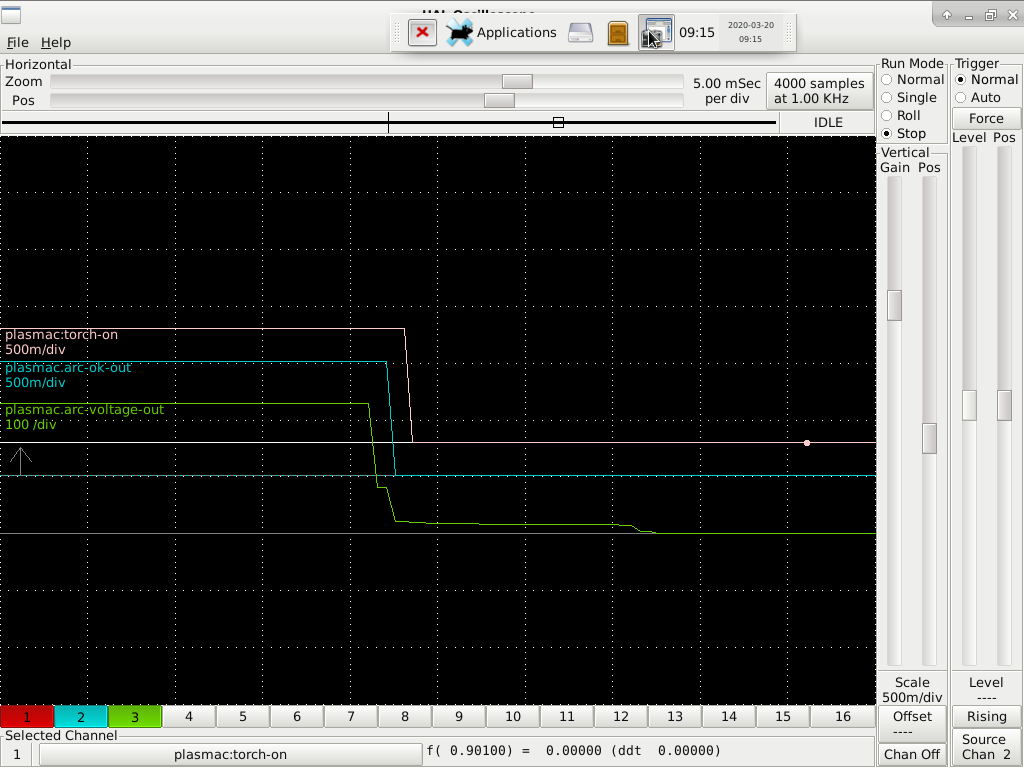

End trace 5ms

.

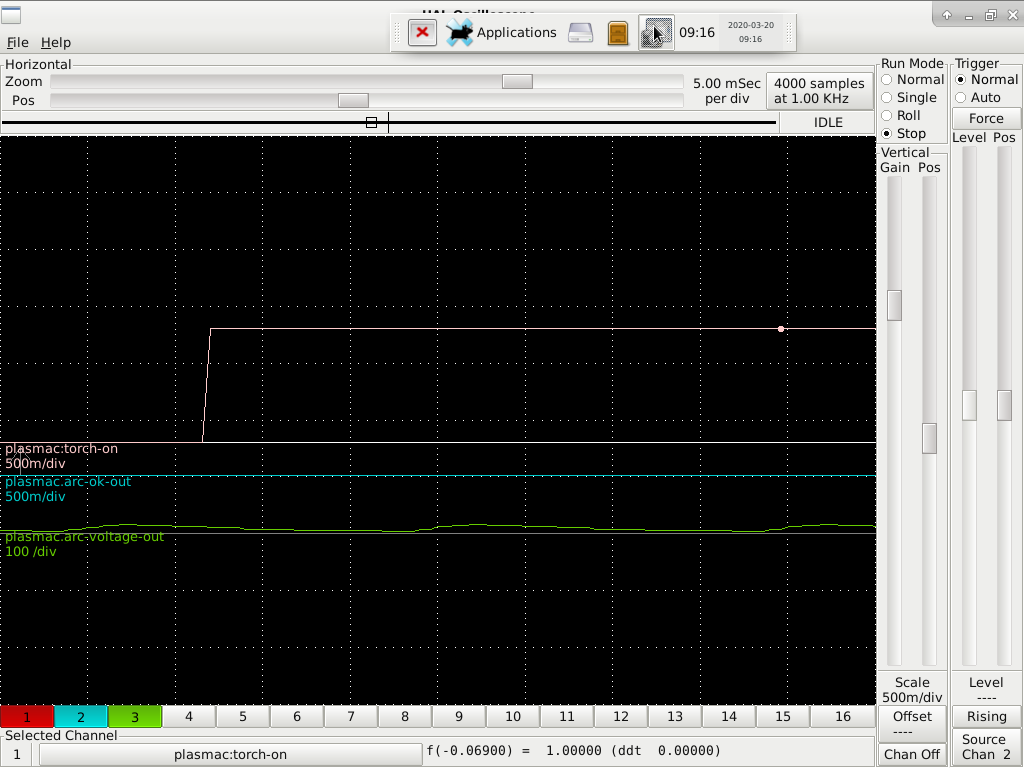

start trace 5ms

.

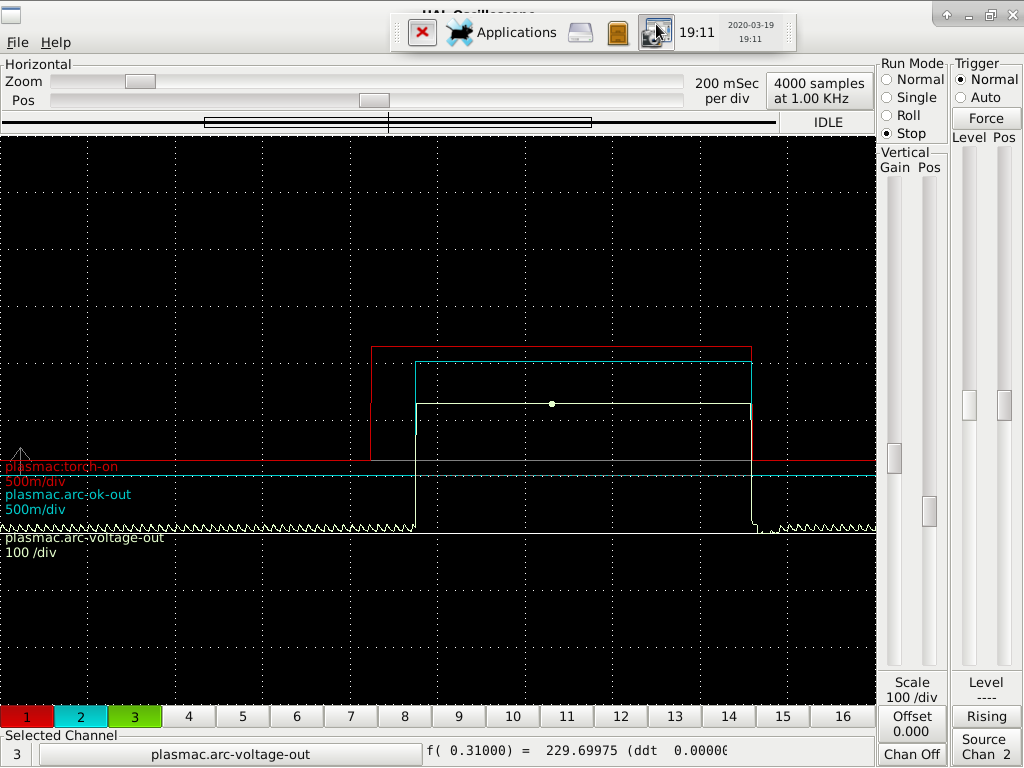

full trace 200ms

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

It seems Tom and Rod are on the right track about the pilot arc not transferring so the pilot arc turns off.

It may be worthwhile doing some probe tests and check the height. It should end up at Pierce Height until it times out and returns to the start point.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

I would look at your pierce height. Its possible with the air flowing the arc does not have sufficient force to transfer to the material. Its clear that there is no current sensed through the work ground cable. Was your plasma designed to accpet a pilot arc torch? IS the new torch compatible?

[/quote]

I purchased my machine and torch at the same time. In fact I had a long conversation with them to make sure it was pilot arc.

The machine originally was sold with a hand torch but they kindly paired it with the 80A machine torch and they also wired the plug with the correct connections for that torch.

Here is a short vid showing that the torch will fire in air with a button I wired across the relay contacts.

photos.app.goo.gl/6zcqkkwaVM8b5MBN8

I have noticed that when the button is pressed it stops the air purge briefly

Please Log in or Create an account to join the conversation.