PlasmaC torch starting problem (Solved with help from the famous three)

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

.[="tommylight" post=160819]Clive, i am sorry for the mess we have created for you, and also sorry for having to ask you this, but several posts back i asked you to check the torch distance from the material after the first and the second probe, now Rod has mentioned the same thing, so please do check that.

I have done that and they are the same

.

.So to recap:

-Please do not lower the low voltage threshold ever again, it did cause us some head scratching, and some stray answers .....,

-PlasmaC is configured and working correctly,

-Wiring is all good,

-The noise is present while the inverter power stage is on, so nothing to worry about, most probably,

-Please oh please lower the pierce height and the cut height !

Pierce at 2mm and cut to 1mm, test and report back

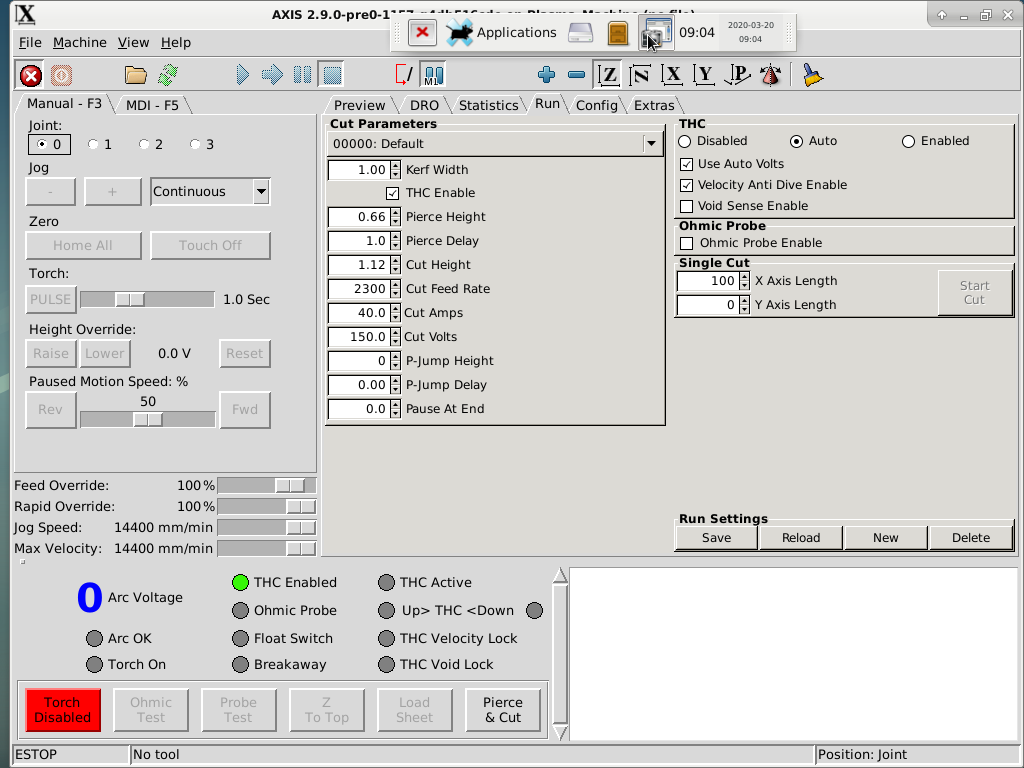

pierce height is 1mm - cut height is 1.12 - Low voltage threshold is 60V

.

I have posted this vid on Rods post as well photos.app.goo.gl/6zcqkkwaVM8b5MBN8

I noticed the air purge stops briefly when the button across the relay contacts is pressed. The button need to be pressed for about 250ms

I also noticed some times when the button is pressed I see a weak pilot but then it always goes to the full pilot

.

.If you can find a reed relay, you can get the arcok signal that never fails and gives no false starts ever, but you do have to remove one of the thick cables on the plasma and replace it with a longer one, with 3 turns made out of it and the reed relay located inside those turns. Use a piece of old pen or similar to prevent the reed relay from braking, they usually are made out of thin glass.

I probably have a reed switch (not relay) as they are in a lot of alarm contacts.

.

.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21243

- Thank you received: 7252

I probably have a reed switch (not relay) as they are in a lot of alarm contacts.

They are also found in satellite dish motors, under a small magnet and are made of plastic, not glass.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Yes, I believe this is correct. PlasmaC will only continue if both are true even though Arc OK is capable of being displayed without a Torch On signal.I may be missing something here. It seems to me that the PlasmaC generated Ark Ok signal should only be true when the plasmac torch on signal is true

@Clive.

Did you try a probe test?

I think you have your Pierce and Cut Heights reversed.

It may be worthwhile checking you gas pressure and setting it toward the lower end of the recommended setting.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11695

- Thank you received: 3947

I have noticed that when the button is pressed it stops the air purge briefly

I'm not sure that firing a torch in the air without cutting something proves anything. Its the arc transfer is the issue.

Does this interruption of the air flow happen when the CNC triggers it with a relay? If not, what is different about your switch and the relay?

Sounds like the air is halted to allow the pilot arc to fire when you press the button.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Yes and I think it is ok

Yes, I believe this is correct. PlasmaC will only continue if both are true even though Arc OK is capable of being displayed without a Torch On signal.I may be missing something here. It seems to me that the PlasmaC generated Ark Ok signal should only be true when the plasmac torch on signal is true

@Clive.

Did you try a probe test?

I think you have your Pierce and Cut Heights reversed.

It may be worthwhile checking you gas pressure and setting it toward the lower end of the recommended setting.

Did you see the vid I posted in Rods answer re the pilot arc with a button across the relay contacts.

photos.app.goo.gl/CMsrzHHvmNoPguUR9

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21243

- Thank you received: 7252

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

.

I have noticed that when the button is pressed it stops the air purge briefly

I'm not sure that firing a torch in the air without cutting something proves anything. Its the arc transfer is the issue.

Does this interruption of the air flow happen when the CNC triggers it with a relay? If not, what is different about your switch and the relay?

OK the switch is wired across the relay contacts so it is doing what the relay should do.

Its hard to see with the relay as it drops out to quick.

.

When it probes for the fail cut (ie the second one) I can press the button and hold it for about 1sec then release and the cut will continue.

.Sounds like the air is halted to allow the pilot arc to fire when you press the button.

Yes it does But if we could get the relay to stop on longer it should work

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Did you try to do several consecutive short cuts by hand, see if it miss fires.

yes. ..I only had the torch in the air to show that it was firing fine.

.

Also I hear a relay probably the solenoid inside the plasma click when I press the button and the air slows

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21243

- Thank you received: 7252

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Actual cuts, the pilot is working, but to know if the transfer is working, actual cuts have to be made.

Do you mean jog the z down to height then press the button and keep it down then jog to do a cut say about 50mm

Please Log in or Create an account to join the conversation.