PlasmaC torch starting problem (Solved with help from the famous three)

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11600

- Thank you received: 3900

It seems like your machine is not a candidate for synthesised ArcOK.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

Why don't you try a timedelay of say 0.2 to 0.5 seconds after torch on and use that as a ArcOK? Leave it on until the cut is finished.

It seems like your machine is not a candidate for synthesised ArcOK.

Would you mind expanding how to achieve that, ie where would the time delay be put and how do I change it as ArkOK.

Before your post . I have been testing again and notice that the ArkOK stops on until the volts drop to zero which take a few seconds to do that. I can fire the torch using a push button across the relay contacts when the air is still purging

Edit: Is there anyway I could trick the THC into zero volts at the start. ?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

If a pushbutton can fire the torch then the torch on signal also should.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

On another tack it may be worth trying the lowpass filter as explained here:

linuxcnc.org/docs/devel/html/plasma/plas...r-guide.html#lowpass

Again you would need to have Arc OK Low higher than the stray voltage.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

It would probably be worthwhile running Halscope on these pins plasmac:torch-on plasmac:arc-ok-out plasmac:arc-voltage-out

On another tack it may be worth trying the lowpass filter as explained here:

linuxcnc.org/docs/devel/html/plasma/plas...r-guide.html#lowpass

Again you would need to have Arc OK Low higher than the stray voltage.

Thanks for your time Phil. I am sorry to be a pain.

I have tried ArkOK at various volts up to 100.

The relay that fires the torch just briefly triggers but does not hold on.

I have tried the lowpass filter was at zero have tried 50,100,200 and with ArcOK_Low at 100.

it doe not change the hovering volts 0-20 after the cut

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11600

- Thank you received: 3900

Why don't you try a timedelay of say 0.2 to 0.5 seconds after torch on and use that as a ArcOK? Leave it on until the cut is finished.

It seems like your machine is not a candidate for synthesised ArcOK.

Would you mind expanding how to achieve that, ie where would the time delay be put and how do I change it as ArkOK.

Plasmac Mode 1 allows you attach an ArcOK signal (plasmac.arc_ok_in) so change modes and use the timedelay component with the in pin coming from the Torch On signal. (plasmac:torch-on) I'll let Phill confirm I have the right pins. Connect the timedelay.out pin to the ArcOK input.

I initially thought of using some sort of latch component but there did not seem to be one available in hal.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

It would probably be worthwhile running Halscope on these pins plasmac:torch-on plasmac:arc-ok-out plasmac:arc-voltage-out

ArcOK high is set at 200What is your Arc OK High set at?

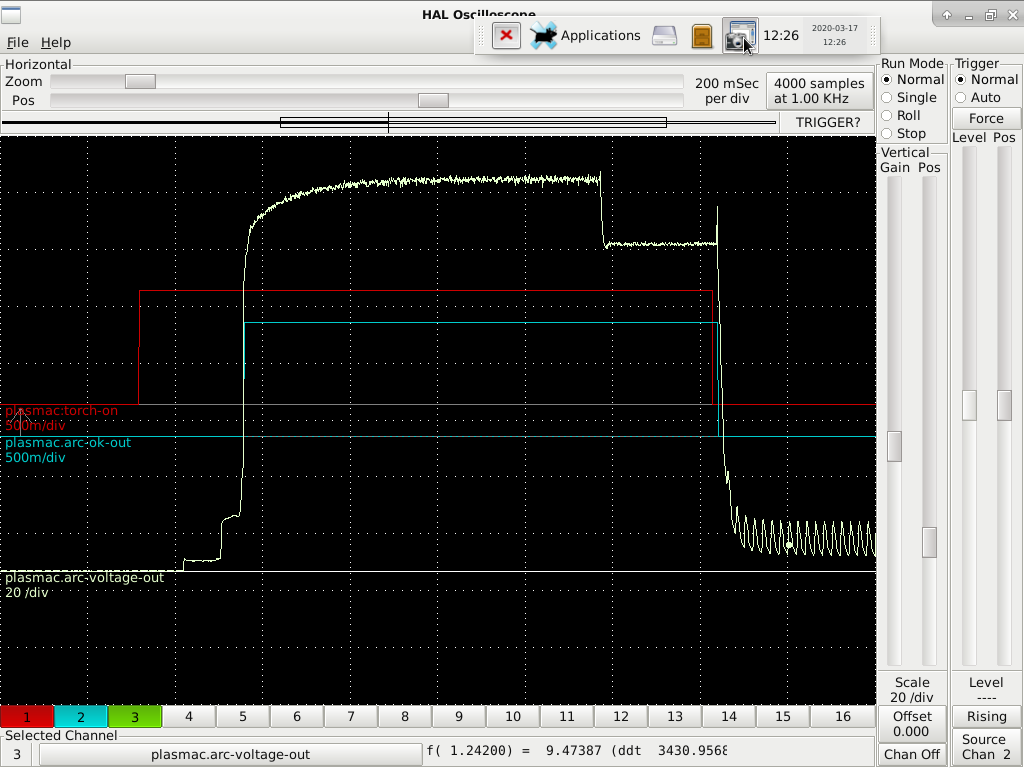

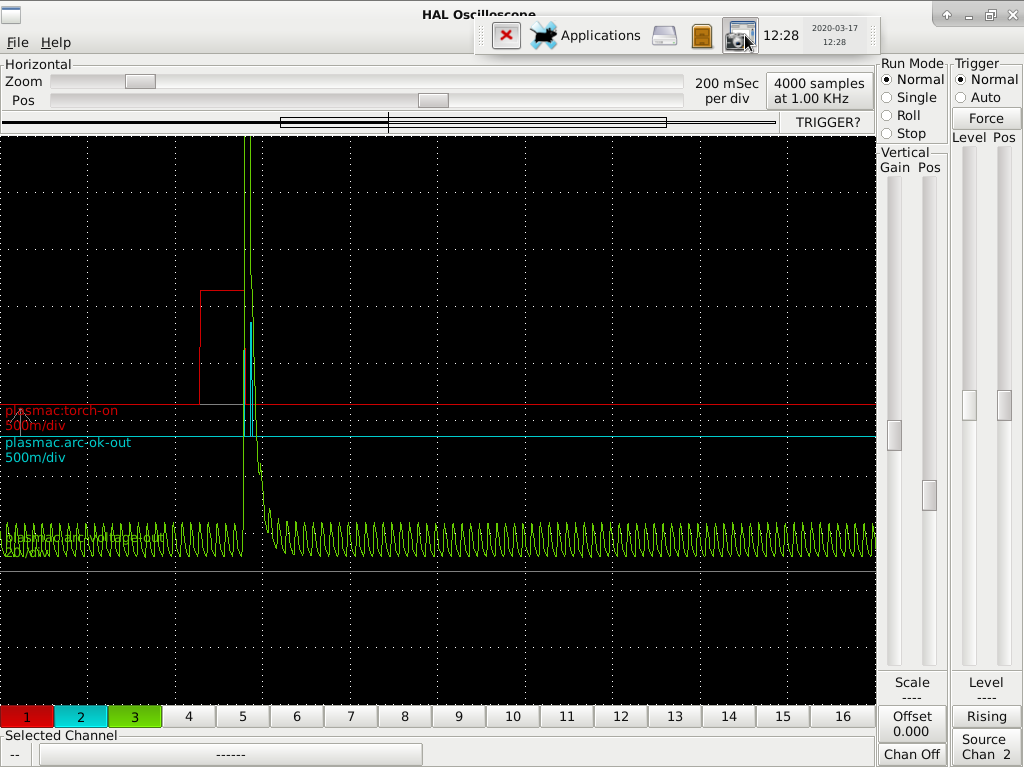

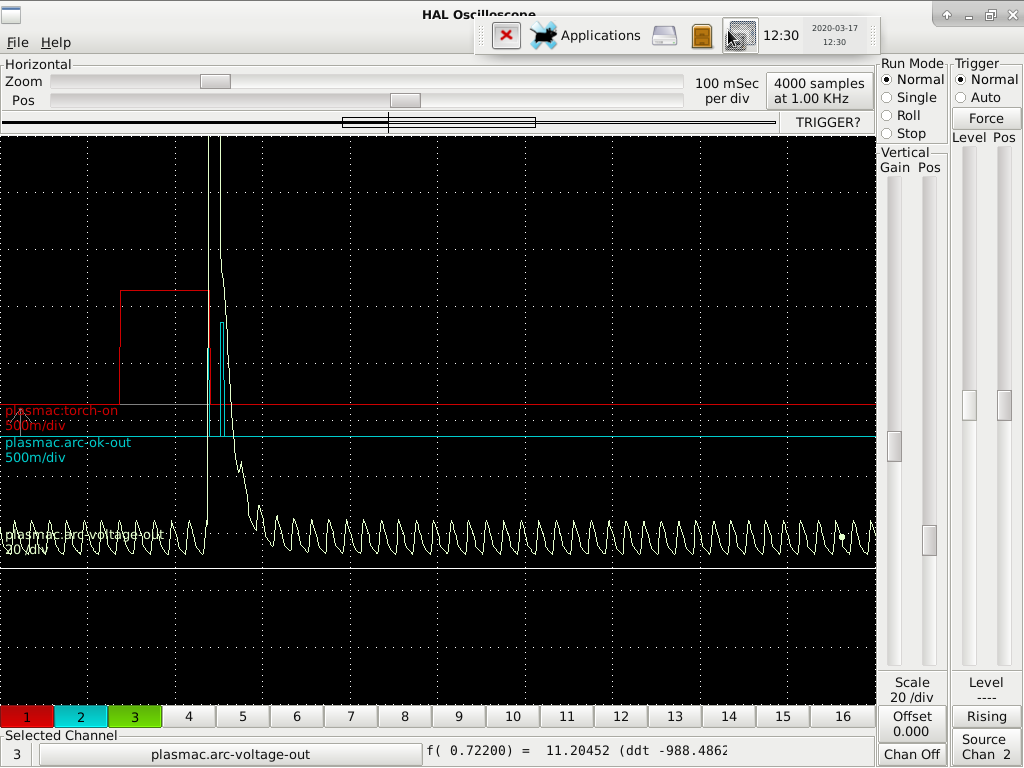

screen shots. The top one is the first cut that works fine the next two are fails ie. arc fail

The above are at the 200 mSec per div scale and the below at at 100 mSec per div

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11600

- Thank you received: 3900

There is a noise issue in your system. I feel your pain.

From memory you have a 7i96,

Have you got an EMI Filter on the mains power? If you have not got an IEC connector you can get hard wired ones.

Is your plasma cutter earthed separate to your mains inlet to power?

Is your table grounded.

Have you got a central ground point with seperate wires back to every motor on your system that bridges all your linear rails? This also needs to be extended to your floating head etc. Hypertherm have a good document on this

BUt the most effective for me was the EMI filter.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

Clive, there is something wrong here with that sawtooth. that is oscillating in sympathy with with your 50 Hz mains power.

There is a noise issue in your system. I feel your pain.

From memory you have a 7i96,

Have you got an EMI Filter on the mains power? If you have not got an IEC connector you can get hard wired ones.

Is your plasma cutter earthed separate to your mains inlet to power?

Is your table grounded.

Have you got a central ground point with seperate wires back to every motor on your system that bridges all your linear rails? This also needs to be extended to your floating head etc. Hypertherm have a good document on this

BUt the most effective for me was the EMI filter.

Rod.. Many thanks for the comments.

Re the above. I have built more that 12 machines and I think I understand the importance of grounding which you are correct to point out.

Yes I have a 7i96 and yes I have a hard wired 10A EMI filter

The actual plasma cuter does not have a separate ground (earth) connection so am relying on the 3 pin plug. I also have tried powering the plasma from another socket. I will also bond the case to the machine frame to see if that make a difference .

I have bonded the Z,X and Y axis to my star ground including all the stepper shields.

If you look on the first halscope there is no 50 HZ showing at the start of the trace and only comes in after the cut.

But on the failed cut it starts with the 50HZ.

I did not check to see the the 50HZ stopped when the air stopped purging. I will though in the morning.

control box photos.app.goo.gl/4Bfb1wv8APv84wAV6

Please Log in or Create an account to join the conversation.