Arc OK intermitent issues on torch fire

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 16

Using the spindle relay is OK on a 7i76. Thats how PCW suggested and it saves an output but I must confess, I never rewired mine from the output I started with after I read his advice.

Do you think its worth trying a different output for said connection if that could be the issue? otherwise i am still just racking my brain trying to figure this one out.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

Also got word back that its a dry contact.

Your arc ok is a dry contact relay inside the plasma cutter, yes.

I’m saying some machines are sensitive to using a solid state switch to control “torch on”.

This would not work for me, I had to change the torch on to a dry contact mechanical relay. In my case, it’s specifically what Hypertherm calls for. When I get to work I’ll link a video (if I still have one) of what my torch used to do. It’s exactly like your first video.

Please Log in or Create an account to join the conversation.

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 16

Also got word back that its a dry contact.

Your arc ok is a dry contact relay inside the plasma cutter, yes.

I’m saying some machines are sensitive to using a solid state switch to control “torch on”.

This would not work for me, I had to change the torch on to a dry contact mechanical relay. In my case, it’s specifically what Hypertherm calls for. When I get to work I’ll link a video (if I still have one) of what my torch used to do. It’s exactly like your first video.

that would be great cheers.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

I would use the timedelay component and connect the torch on signal to that. Set the delay for about 0.2 seconds

Use timedelay.N.out for your ArcOK.

See: linuxcnc.org/docs/2.8/html/man/man9/timedelay.9.html

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

I've said this before but no one listened... but its such a simple solution.

I would use the timedelay component and connect the torch on signal to that. Set the delay for about 0.2 seconds

Use timedelay.N.out for your ArcOK.

See: linuxcnc.org/docs/2.8/html/man/man9/timedelay.9.html

PlasmaC can already do this natively. It's probably not the appropriate solution to this gentleman's problem though.

linuxcnc.org/docs/devel/html/plasma/plas...html#_lost_arc_delay

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

Also got word back that its a dry contact.

Your arc ok is a dry contact relay inside the plasma cutter, yes.

I’m saying some machines are sensitive to using a solid state switch to control “torch on”.

This would not work for me, I had to change the torch on to a dry contact mechanical relay. In my case, it’s specifically what Hypertherm calls for. When I get to work I’ll link a video (if I still have one) of what my torch used to do. It’s exactly like your first video.

that would be great cheers.

Here you go:

You'll have to take my word for it that there is in fact a tiny arc there. Also, I did have another video after I changed to a dry contact relay, but it legit just shows the torch pulsing as it should and I don't have enough service where I am to upload it currently. At any rate, when my ground cable was near the table, the arc would be stronger. I would often lose valid arc ok at the beginning of a cut, or a second or so into a cut, etc. I was really pulling out my hair until I went to a manual torch to cut something else and the ground clamp wasn't hooked to anything and it all worked fine. Switched it over and it's been find since.

I would look at it like this: It doesn't work right now. The worst thing that can happen is you switch the output and use a mechanical relay, and it still doesn't work. Then you switch it back if you want. Otherwise it solves the problem, Bob's your uncle, and you go on happily cutting.

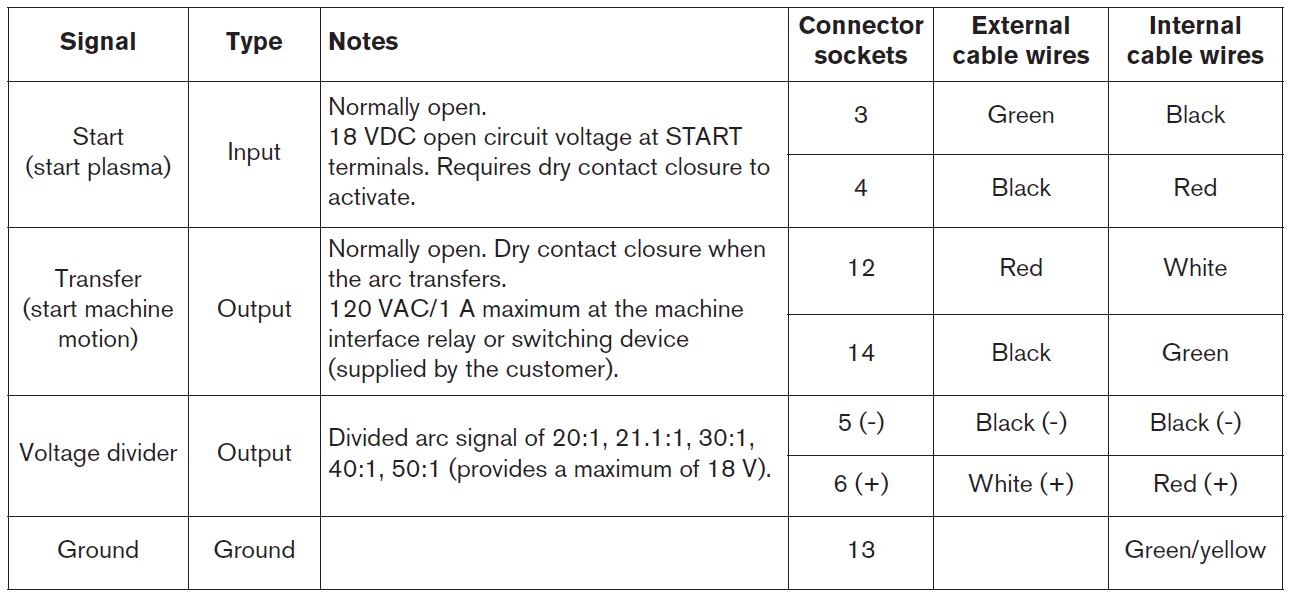

Below is an excerpt from the hypertherm manual which shows requiring dry contact closure to activate:

It seems some people get away with using a SSR. It was a problem for me.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

I've said this before but no one listened... but its such a simple solution.

I would use the timedelay component and connect the torch on signal to that. Set the delay for about 0.2 seconds

Use timedelay.N.out for your ArcOK.

See: linuxcnc.org/docs/2.8/html/man/man9/timedelay.9.html

PlasmaC can already do this natively. It's probably not the appropriate solution to this gentleman's problem though.

linuxcnc.org/docs/devel/html/plasma/plas...html#_lost_arc_delay

Plasmac has some native handling but what I propose is bypassing Plasmac and always enforcing Arc OK. I think as has been reported in the past that Plasmac gets confused with HF induced voltage fluctuations. Please don't poo poo considered advice from someone who has been playing with plasma cutting for several years before Plasmac was even conceived and has studied thousands of voltage plots.

This gentleman's problems will be solved if he follows my advice and it won't cost him a cent.

I personally think your concerns about the spindle relay are unfounded. There are a number of users following that approach and I've been using an optocoupled relay for the last two years to trigger my torch without any issues.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

The aforementioned feature was added 1 month ago. He IS getting a valid arc ok at least for a few mS, or he wouldn't get the "valid arc-ok lost". The new (1 month ago) feature allows a user to set a pin with a time period for PlasmaC to force the arc-ok true AFTER it loses the signal, without interruption. Which is essentially what you're proposing. Otherwise, to bypass the arc ok completely, without your free solution, he could just click "ignore arc-ok".Plasmac has some native handling but what I propose is bypassing Plasmac and always enforcing Arc OK.

The RAZOR CUT 45 (what OP has) is a "low frequency pilot arc" plasma cutter.I think as has been reported in the past that Plasmac gets confused with HF induced voltage fluctuations.

Not sure I "poo poo"'d anything? I guess I missed the voltage plots? Or was that just irrelevant rambling/chest pounding? Either way, it doesn't mean my experiences have no merit.Please don't poo poo considered advice from someone who has been playing with plasma cutting for several years before Plasmac was even conceived and has studied thousands of voltage plots.

Perhaps, but it caused me a very similar issue, and changing it to what the manual calls for fixed it.I personally think your concerns about the spindle relay are unfounded. There are a number of users following that approach and I've been using an optocoupled relay for the last two years to trigger my torch without any issues.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21163

- Thank you received: 7228

Update PlasmaC to at least version 0.182

Use a hardware ARCOK if possible

Software ARCOK works properly, it is just trickier to set up.

If torch on is working, leave it as is. To test it, use the MESH/Ignore ArcOK feature in PlasmaC and cut something while watching the ARCOK input on halshow or halmeter.

B.T.W, there might be cases when an opto can cause issues with starting something. To long ....

Please Log in or Create an account to join the conversation.

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 16

I feel sorry for the OP.....

Update PlasmaC to at least version 0.182

Use a hardware ARCOK if possible

Software ARCOK works properly, it is just trickier to set up.

If torch on is working, leave it as is. To test it, use the MESH/Ignore ArcOK feature in PlasmaC and cut something while watching the ARCOK input on halshow or halmeter.

B.T.W, there might be cases when an opto can cause issues with starting something. To long ....

Ok so i just did around 40 cuts with meshmode and not one issue while starting the arcs, could the machine be getting a false arcok reading within the first 1 second triggering the invalid arc maybe? (short video of screen)

Please Log in or Create an account to join the conversation.