Arc OK intermitent issues on torch fire

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

23 Dec 2020 23:04 #193039

by tommylight

Replied by tommylight on topic Arc OK intermitent issues on torch fire

Check the torch by removing the cap and checking everything is in place and properly tightened/seated, electrode, swirl ring and nozzle.

Also just in case, check if the ground clamp is clamped to the table.

Also just in case, check if the ground clamp is clamped to the table.

The following user(s) said Thank You: luftlupus

Please Log in or Create an account to join the conversation.

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 84

- Thank you received: 16

23 Dec 2020 23:16 - 23 Dec 2020 23:17 #193040

by luftlupus

You some kind of prophet? cause i just checked it and swapped everything on the end just to be sure swirlring/retaining cap/electrode/tip and it fired... something so simple... only lets me thank you once but THANKS!!

Replied by luftlupus on topic Arc OK intermitent issues on torch fire

Check the torch by removing the cap and checking everything is in place and properly tightened/seated, electrode, swirl ring and nozzle.

Also just in case, check if the ground clamp is clamped to the table.

You some kind of prophet? cause i just checked it and swapped everything on the end just to be sure swirlring/retaining cap/electrode/tip and it fired... something so simple... only lets me thank you once but THANKS!!

Last edit: 23 Dec 2020 23:17 by luftlupus.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

23 Dec 2020 23:20 #193041

by tommylight

Replied by tommylight on topic Arc OK intermitent issues on torch fire

The following user(s) said Thank You: luftlupus

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

23 Dec 2020 23:34 #193042

by tommylight

Replied by tommylight on topic Arc OK intermitent issues on torch fire

Just as info in one place, in case the air starts but there is no pilot arc and subsequently no cutting, check in this order:

-Air pressure while the air is running, should be 4.5 to 5.5 bar,

-Check if the consumables are properly seated/tightened,

-If the consumables are used, change them, even if they still look usable, the black stuff that collects there will in some cases prevent a pilot arc.

In case all of the above fails, find some thin wire about 1cm in length and insert it in the nozzle orifice leaving one part protruding out, carefully set the torch so the wire is in contact with some scrap material then press the trigger to fire the torch while slowly moving the torch over the material.

The above last past is to check if the pilot arc and the high power parts of the plasma source are working, if the procedure works and produces a cut then the high power part is ok and there is a failure in the pilot part of the machine.

Also the above is valid for plasma sources having separate electronics for pilot and cut, does work even for blow back torches to reveal if the power stage is ok leaving the only culprit the electrode/spring or torch seat for them.

-Air pressure while the air is running, should be 4.5 to 5.5 bar,

-Check if the consumables are properly seated/tightened,

-If the consumables are used, change them, even if they still look usable, the black stuff that collects there will in some cases prevent a pilot arc.

In case all of the above fails, find some thin wire about 1cm in length and insert it in the nozzle orifice leaving one part protruding out, carefully set the torch so the wire is in contact with some scrap material then press the trigger to fire the torch while slowly moving the torch over the material.

The above last past is to check if the pilot arc and the high power parts of the plasma source are working, if the procedure works and produces a cut then the high power part is ok and there is a failure in the pilot part of the machine.

Also the above is valid for plasma sources having separate electronics for pilot and cut, does work even for blow back torches to reveal if the power stage is ok leaving the only culprit the electrode/spring or torch seat for them.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 84

- Thank you received: 16

24 Dec 2020 00:02 #193046

by luftlupus

Will add this to my notes. cheers

Replied by luftlupus on topic Arc OK intermitent issues on torch fire

Just as info in one place, in case the air starts but there is no pilot arc and subsequently no cutting, check in this order:

-Air pressure while the air is running, should be 4.5 to 5.5 bar,

-Check if the consumables are properly seated/tightened,

-If the consumables are used, change them, even if they still look usable, the black stuff that collects there will in some cases prevent a pilot arc.

In case all of the above fails, find some thin wire about 1cm in length and insert it in the nozzle orifice leaving one part protruding out, carefully set the torch so the wire is in contact with some scrap material then press the trigger to fire the torch while slowly moving the torch over the material.

The above last past is to check if the pilot arc and the high power parts of the plasma source are working, if the procedure works and produces a cut then the high power part is ok and there is a failure in the pilot part of the machine.

Also the above is valid for plasma sources having separate electronics for pilot and cut, does work even for blow back torches to reveal if the power stage is ok leaving the only culprit the electrode/spring or torch seat for them.

Will add this to my notes. cheers

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

31 Mar 2021 18:00 #204250

by txtrone

Are you referring to the cap going across the pos and neg, rather than being inline on the pos?

Do you have an opinion on using a resistor vs cap in this setup?

I am currently wiring my hypertherm pm85 and my head is about to explode from all of the (well intentioned) conflicting information I am getting. It reminds me of conversations/debates/arguments I have witnessed over the years between master electricians and electrical engineers. "You can't do that! It will NOT work!!!" ... "That's interesting, I've been doing it like that for 30 years!!!" etc etc

Replied by txtrone on topic Arc OK intermitent issues on torch fire

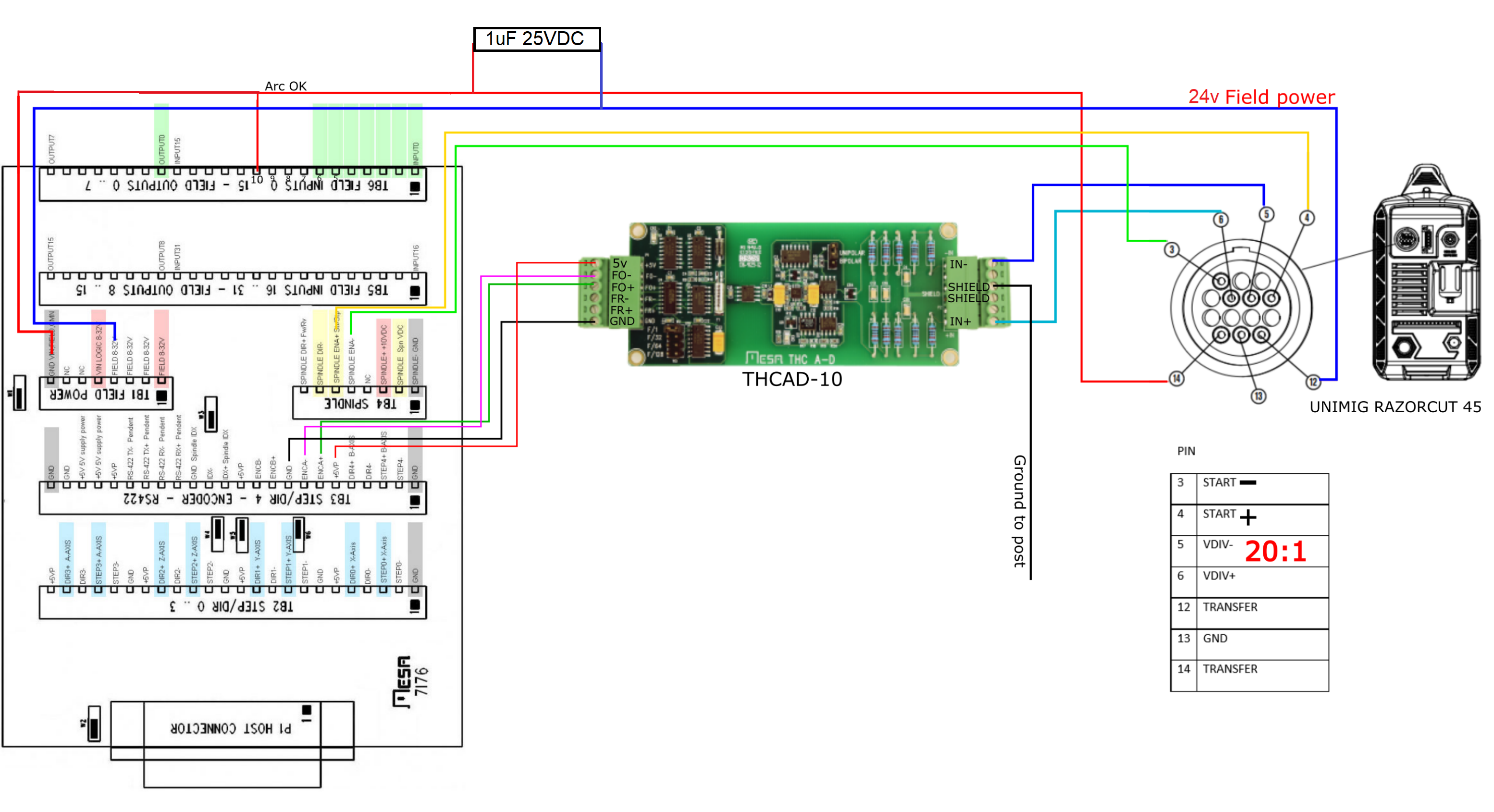

Last post first schematics shows a wiring error that will cause the ARCOK (transfer) to short the VFIELD power.

I really hope it is not wired like that.

Are you referring to the cap going across the pos and neg, rather than being inline on the pos?

Do you have an opinion on using a resistor vs cap in this setup?

I am currently wiring my hypertherm pm85 and my head is about to explode from all of the (well intentioned) conflicting information I am getting. It reminds me of conversations/debates/arguments I have witnessed over the years between master electricians and electrical engineers. "You can't do that! It will NOT work!!!" ... "That's interesting, I've been doing it like that for 30 years!!!" etc etc

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

31 Mar 2021 19:09 #204267

by snowgoer540

In the diagram that post is referring to, the field power + side is wired directly to the input for arc ok. It was a mistake in the diagram.

As for resistor vs cap, it’s two different ways to skin the same cat.

From my rudimentary understanding, resistor forces extra current all the time, and does not account for mfg’s different ratings of minimum switching loads at different voltages. Capacitor provides a burst of electricity for cleaning the contacts at close but doesn’t pull extra amperage all the time.

Here’s a link that may help: en.m.wikipedia.org/wiki/Wetting_current

There are plenty of resources out there to research and draw your own informed decision.

I’m not an electrical engineer. But if I were going to run one (have not yet found this to be necessary with my hypertherm 65 (but the fact that contact oxidation and minimum switching currents are a real thing is filed away for later)) I would likely pick the capacitor. It was far more important in my setup to add a debounce to the arc ok input. Which is now standard at 5mS. I’ve seen others need as much as 10mS. At any rate, your local humidity/temperature/etc may be different.

Replied by snowgoer540 on topic Arc OK intermitent issues on torch fire

Last post first schematics shows a wiring error that will cause the ARCOK (transfer) to short the VFIELD power.

I really hope it is not wired like that.

Are you referring to the cap going across the pos and neg, rather than being inline on the pos?

Do you have an opinion on using a resistor vs cap in this setup?

I am currently wiring my hypertherm pm85 and my head is about to explode from all of the (well intentioned) conflicting information I am getting. It reminds me of conversations/debates/arguments I have witnessed over the years between master electricians and electrical engineers. "You can't do that! It will NOT work!!!" ... "That's interesting, I've been doing it like that for 30 years!!!" etc etc

In the diagram that post is referring to, the field power + side is wired directly to the input for arc ok. It was a mistake in the diagram.

As for resistor vs cap, it’s two different ways to skin the same cat.

From my rudimentary understanding, resistor forces extra current all the time, and does not account for mfg’s different ratings of minimum switching loads at different voltages. Capacitor provides a burst of electricity for cleaning the contacts at close but doesn’t pull extra amperage all the time.

Here’s a link that may help: en.m.wikipedia.org/wiki/Wetting_current

There are plenty of resources out there to research and draw your own informed decision.

I’m not an electrical engineer. But if I were going to run one (have not yet found this to be necessary with my hypertherm 65 (but the fact that contact oxidation and minimum switching currents are a real thing is filed away for later)) I would likely pick the capacitor. It was far more important in my setup to add a debounce to the arc ok input. Which is now standard at 5mS. I’ve seen others need as much as 10mS. At any rate, your local humidity/temperature/etc may be different.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

31 Mar 2021 19:15 #204270

by txtrone

Thanks! I may leave it out for now and see how things go.

Quick side question. I powered my THCAD 10 from the same 'common' PSU as the Mesa board. Is there anything wrong with that? or does it need to get power from the Mesa board?

Replied by txtrone on topic Arc OK intermitent issues on torch fire

In the diagram that post is referring to, the field power + side is wired directly to the input for arc ok. It was a mistake in the diagram.

As for resistor vs cap, it’s two different ways to skin the same cat.

Thanks! I may leave it out for now and see how things go.

Quick side question. I powered my THCAD 10 from the same 'common' PSU as the Mesa board. Is there anything wrong with that? or does it need to get power from the Mesa board?

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

31 Mar 2021 19:27 - 31 Mar 2021 19:27 #204273

by snowgoer540

Assuming you have a 7i96 you should take it from the encoder area of TB2. Looks like TB2 pins 6 (+5v) and pin 9 (gnd). This is for better noise immunity, I believe.

Replied by snowgoer540 on topic Arc OK intermitent issues on torch fire

In the diagram that post is referring to, the field power + side is wired directly to the input for arc ok. It was a mistake in the diagram.

As for resistor vs cap, it’s two different ways to skin the same cat.

Thanks! I may leave it out for now and see how things go.

Quick side question. I powered my THCAD 10 from the same 'common' PSU as the Mesa board. Is there anything wrong with that? or does it need to get power from the Mesa board?

Assuming you have a 7i96 you should take it from the encoder area of TB2. Looks like TB2 pins 6 (+5v) and pin 9 (gnd). This is for better noise immunity, I believe.

Last edit: 31 Mar 2021 19:27 by snowgoer540.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

31 Mar 2021 20:40 - 31 Mar 2021 20:42 #204288

by tommylight

Replied by tommylight on topic Arc OK intermitent issues on torch fire

The above has the red wire directly connected to Vfield, that is wrong as the arc transfer relay will connect that to ground causing a short to the power supply.

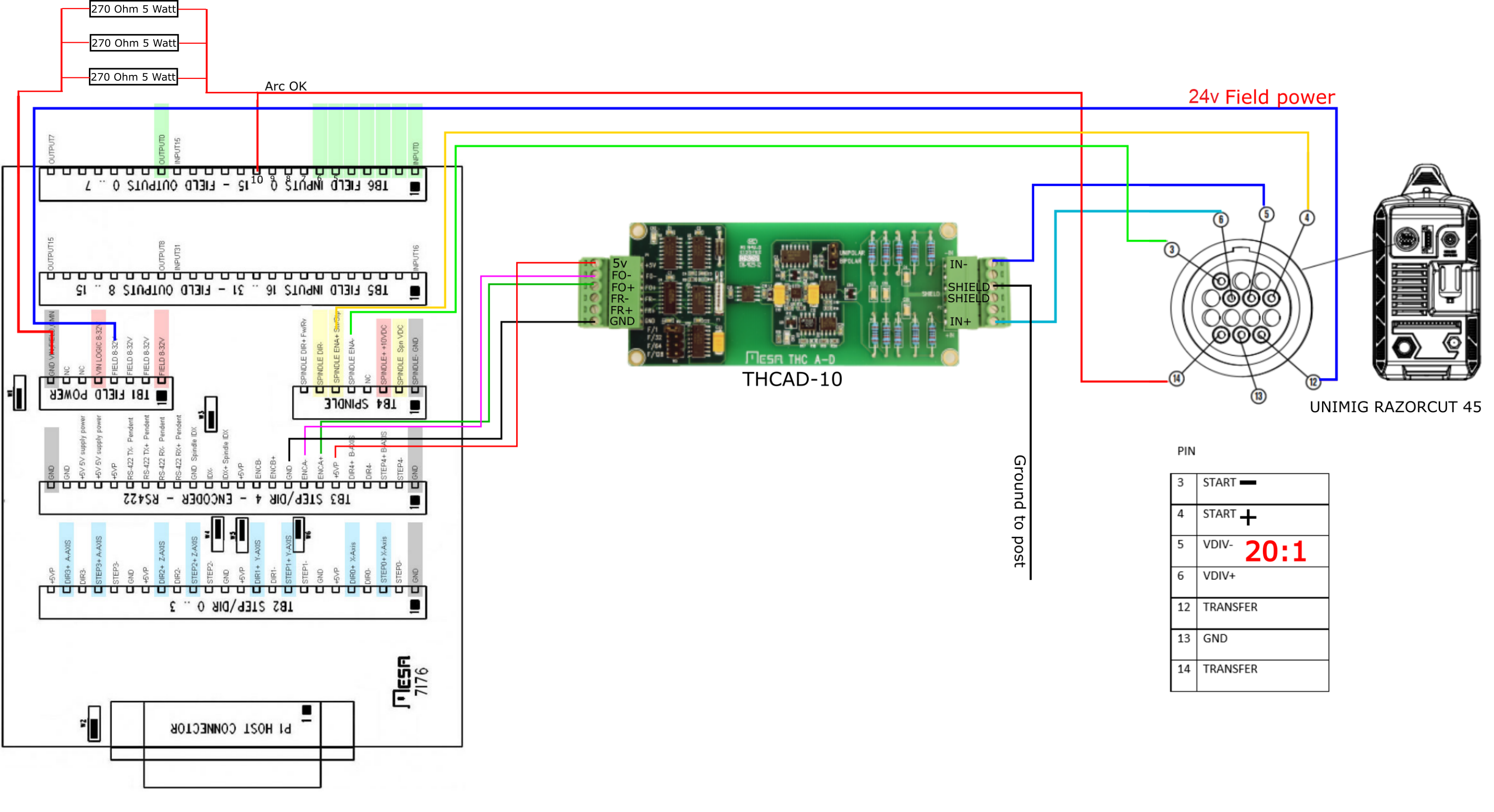

This is correct, notice the resistors between the input and the Vfield on the red wire.

Last edit: 31 Mar 2021 20:42 by tommylight. Reason: wrong attachment

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.136 seconds