Arc OK intermitent issues on torch fire

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

03 Apr 2021 00:07 #204585

by txtrone

Replied by txtrone on topic Arc OK intermitent issues on torch fire

Thank you

Please Log in or Create an account to join the conversation.

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

04 Apr 2021 01:11 #204698

by txtrone

Would this FNQ-1 fuse be adequate?

Replied by txtrone on topic Arc OK intermitent issues on torch fire

The fuses are to protect the sense wires from fault currents so they

should be as close to plasma machine as possible. 1A should be fine

(It should be rate to interrupt the plasma voltage and current)

Would this FNQ-1 fuse be adequate?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

04 Apr 2021 11:23 #204734

by tommylight

Replied by tommylight on topic Arc OK intermitent issues on torch fire

Notice the "time delay" in the pdf, those are slow acting fuses, for electronics use always fast acting ones, they are usually made of see through glass with a very thin wire inside.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

04 Apr 2021 12:11 #204748

by txtrone

What voltage should the fuse be rated for? 250?

Replied by txtrone on topic Arc OK intermitent issues on torch fire

Notice the "time delay" in the pdf, those are slow acting fuses, for electronics use always fast acting ones, they are usually made of see through glass with a very thin wire inside.

What voltage should the fuse be rated for? 250?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17588

- Thank you received: 5143

04 Apr 2021 13:01 #204758

by PCW

Replied by PCW on topic Arc OK intermitent issues on torch fire

0ADAC0600-BE might be a better choice as it's cheaper, has a DC rating

and will fit in a standard 3AG inline fuseholder

and will fit in a standard 3AG inline fuseholder

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

04 Apr 2021 17:41 #204788

by txtrone

I like that price point! Sorry to beat this to death, but earlier you suggested a 1A... this model is 0.6A ... I assume that anything over a half amp on the sense or torch wires is too much and this fuse will break the circuit before anything or anyone gets hurt. Does that sound correct-ish? thx again PCW!

Replied by txtrone on topic Arc OK intermitent issues on torch fire

0ADAC0600-BE might be a better choice as it's cheaper, has a DC rating

and will fit in a standard 3AG inline fuseholder

I like that price point! Sorry to beat this to death, but earlier you suggested a 1A... this model is 0.6A ... I assume that anything over a half amp on the sense or torch wires is too much and this fuse will break the circuit before anything or anyone gets hurt. Does that sound correct-ish? thx again PCW!

Please Log in or Create an account to join the conversation.

- txtrone

-

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

05 Apr 2021 01:11 #204835

by txtrone

Tommylight do you think the ArcOk signaling method created by using 'three turns around the reed relay' is actually a better (or as good as) method than what comes built into many machines today? When I first read about this (your?) method I thought it sounded quite MacGyver-esque... and not the new MacGyver either... the real mid-1980s-OG-MacGyver. Just curious.

Replied by txtrone on topic Arc OK intermitent issues on torch fire

And i do agree on not using any resistor or capacitor, try it without it. I never used any of those on several (count more than 20) and never had issues, but i am pretty sure it might be needed sometimes.

To be fair Tommy, from what you've written over the years, many of the machines you have built did not have a builtin AcOK relay so it was a non issue for them. At least you know to look for the issue if it ever bites you!

Tommylight do you think the ArcOk signaling method created by using 'three turns around the reed relay' is actually a better (or as good as) method than what comes built into many machines today? When I first read about this (your?) method I thought it sounded quite MacGyver-esque... and not the new MacGyver either... the real mid-1980s-OG-MacGyver. Just curious.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

05 Apr 2021 01:37 #204839

by tommylight

Replied by tommylight on topic Arc OK intermitent issues on torch fire

The derived arcok from THCAD works perfectly although i am sure there might be situations where it might fail but not due the the way it works but due to how plasma sources work.

The reed version has no way of failing if done right as it relies on a big amount of current passing through that wire.

By now i have 4 machines using the derived arcok from thcad and they never failed, but that needs a bit of tweaking, roughly setting the low limit to 60-80V and the high limit to 250V and then gradually lowering it till it starts failing or till it reaches 140-160V and leaving it there. That will prevent the machine getting the arcok in case the torch has fired and it is to high so the current passing through it will be low and the subsequent voltage will be anything from 180 to 280 or more V, causing the plasma to fail the arc as it can not be transferred to cutting power.

Or to put it simpler it MIGHT give arcok even when not cutting at full power in such case. The above tweaking prevents that.

The low side is less important as that would be the case when the torch is very low or touching the material hence the voltage will be low but it will not impede the cutting process, it will just mess up the nozzle.

The reed version has no way of failing if done right as it relies on a big amount of current passing through that wire.

By now i have 4 machines using the derived arcok from thcad and they never failed, but that needs a bit of tweaking, roughly setting the low limit to 60-80V and the high limit to 250V and then gradually lowering it till it starts failing or till it reaches 140-160V and leaving it there. That will prevent the machine getting the arcok in case the torch has fired and it is to high so the current passing through it will be low and the subsequent voltage will be anything from 180 to 280 or more V, causing the plasma to fail the arc as it can not be transferred to cutting power.

Or to put it simpler it MIGHT give arcok even when not cutting at full power in such case. The above tweaking prevents that.

The low side is less important as that would be the case when the torch is very low or touching the material hence the voltage will be low but it will not impede the cutting process, it will just mess up the nozzle.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

05 Apr 2021 04:44 #204857

by rodw

Replied by rodw on topic Arc OK intermitent issues on torch fire

My take is that if you have an arcok output on your plasma cutter be sure to use it.

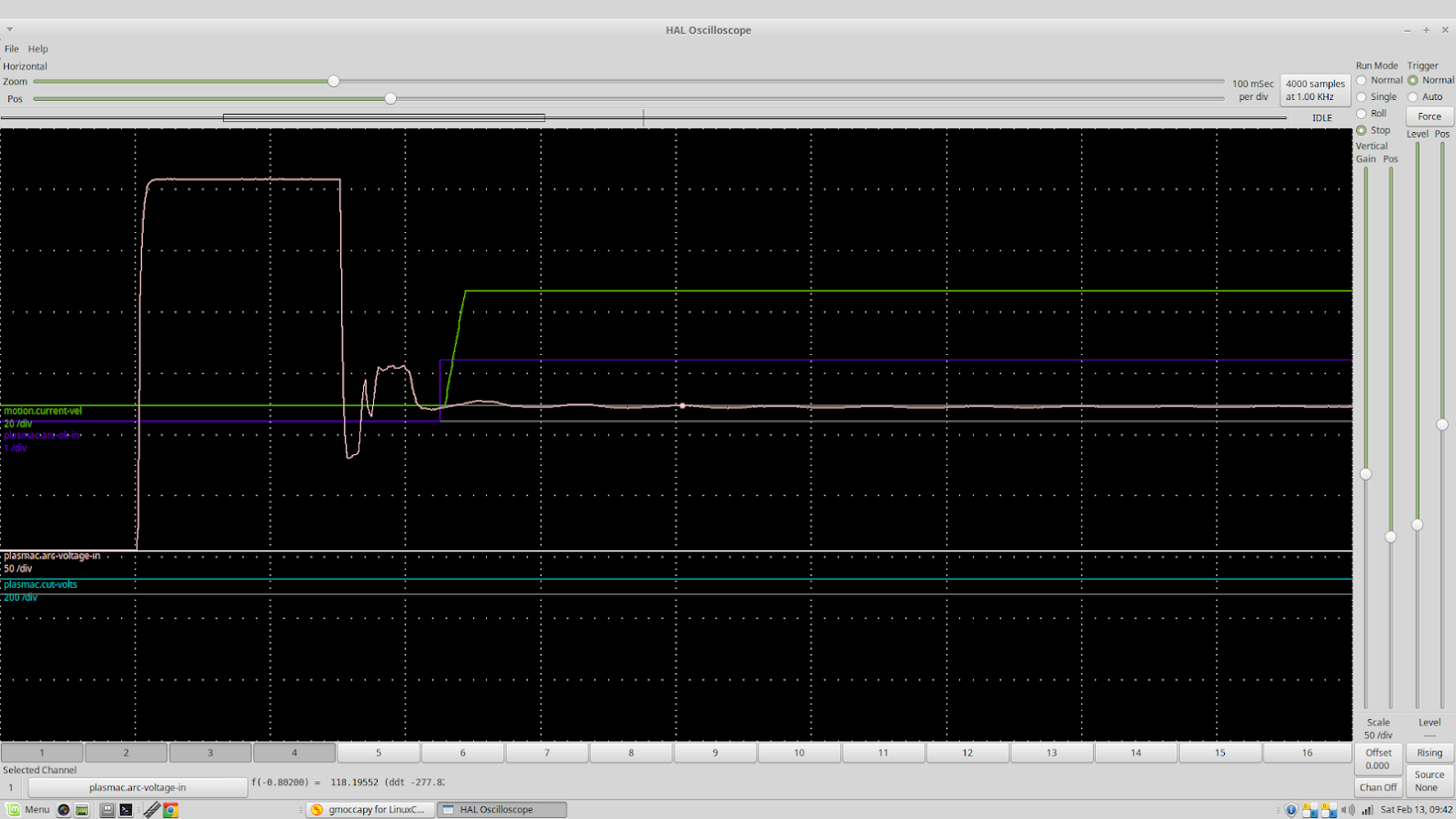

This plot I shared on another thread shows the voltage fluctuation on piercing before the ArcOK is turned on.

See: forum.linuxcnc.org/plasma-laser/41420-arc-voltage-on-piercing

You can see there is quite some fluctuations in the voltage and the risk is that Plasmac's low threshold could force the ArcOK to drop out. The current synthesised ArcOK algorithm is a little simplistic for my liking. The plasma cutter does more work than just looking at the torch voltage before enabling ArcOK. I'd like to see an algorithm based on tracking the arc behaviour shown in the plot.

This plot I shared on another thread shows the voltage fluctuation on piercing before the ArcOK is turned on.

See: forum.linuxcnc.org/plasma-laser/41420-arc-voltage-on-piercing

You can see there is quite some fluctuations in the voltage and the risk is that Plasmac's low threshold could force the ArcOK to drop out. The current synthesised ArcOK algorithm is a little simplistic for my liking. The plasma cutter does more work than just looking at the torch voltage before enabling ArcOK. I'd like to see an algorithm based on tracking the arc behaviour shown in the plot.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

05 Apr 2021 04:57 #204858

by phillc54

Replied by phillc54 on topic Arc OK intermitent issues on torch fire

I have NO issues at all with synthesised ArcOK.

The following user(s) said Thank You: rodw, txtrone

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.094 seconds