Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

22 Jun 2020 10:00 #172315

by rodw

Yeh but NEMA24 does not normally have a 50mm bolt hole pitch. The NEMA24 ones I looked at had the same pitch as the Nema 23 but a different diameter locating flange.

I can't wait to get this turning!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nema 23 = 56mm frame, Nema 24 = 60mm frame !

Yeh but NEMA24 does not normally have a 50mm bolt hole pitch. The NEMA24 ones I looked at had the same pitch as the Nema 23 but a different diameter locating flange.

I can't wait to get this turning!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

22 Jun 2020 10:09 #172318

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

I am not that lucky, all the Nema 24 i have have different pitch, just enough to not fit at all !

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

23 Jun 2020 08:09 #172447

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well, this is what happens when you play with your machine. I found there was some tight spots on the X axis and when I had a look at it, I tightened up all the bolts holding the rack and linear rails and found one missing mounting bolt on the rack which I replaced.. I guess it was time to do some maintenance,

Then I found the X axis pinion shaft I made was quite loose with worn bearings so I spent the afternoon stripping down the pinion and ended up ordering another Flange bearing which is coming via airbag from Perth on the other side of the country. I was missing the correct retaining nut on the old one which is probably why it came loose and wore.

I don't think I totally fixed the tight spots but its a lot better now.

Then I went looking for a NEMA 24 mounting bracket to upgrade my Z axis. I finally found one and it looks a lot better than what I had. Except its 100 mm wide and it has to fit on a 60mm wide backing plate so an adapter is in order. Nothing is easy! Anyway, this is coming via DHL..

www.aliexpress.com/item/32969053665.html...1.0.0.4d634c4dGW7sFL

And I am so impressed with these Sanyo Denki motors, I bought out what was left so have another 15 coming. They just had no idea what they were really worth! (Or where to buy the wiring harnesses possibly!)

Then I found the X axis pinion shaft I made was quite loose with worn bearings so I spent the afternoon stripping down the pinion and ended up ordering another Flange bearing which is coming via airbag from Perth on the other side of the country. I was missing the correct retaining nut on the old one which is probably why it came loose and wore.

I don't think I totally fixed the tight spots but its a lot better now.

Then I went looking for a NEMA 24 mounting bracket to upgrade my Z axis. I finally found one and it looks a lot better than what I had. Except its 100 mm wide and it has to fit on a 60mm wide backing plate so an adapter is in order. Nothing is easy! Anyway, this is coming via DHL..

www.aliexpress.com/item/32969053665.html...1.0.0.4d634c4dGW7sFL

And I am so impressed with these Sanyo Denki motors, I bought out what was left so have another 15 coming. They just had no idea what they were really worth! (Or where to buy the wiring harnesses possibly!)

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

23 Jun 2020 16:17 #172485

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Welcome to the club !And I am so impressed with these Sanyo Denki motors,...

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

25 Jun 2020 02:23 #172673

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

25 Jun 2020 11:58 #172710

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Yummy !

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

01 Jul 2020 22:50 #173357

by my1987toyota

Replied by my1987toyota on topic Rods "Spaceship" Scratch built Plasma Cutter build

well rodw since you took the the time to check out my machine I decided to reply in kind. That plasma table looks fantastic . Well done.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

02 Jul 2020 08:59 #173385

by rodw

Well we Toyota drivers have to stick together regardless of where we are in the world! I'd like to think this thread will get interesting again!

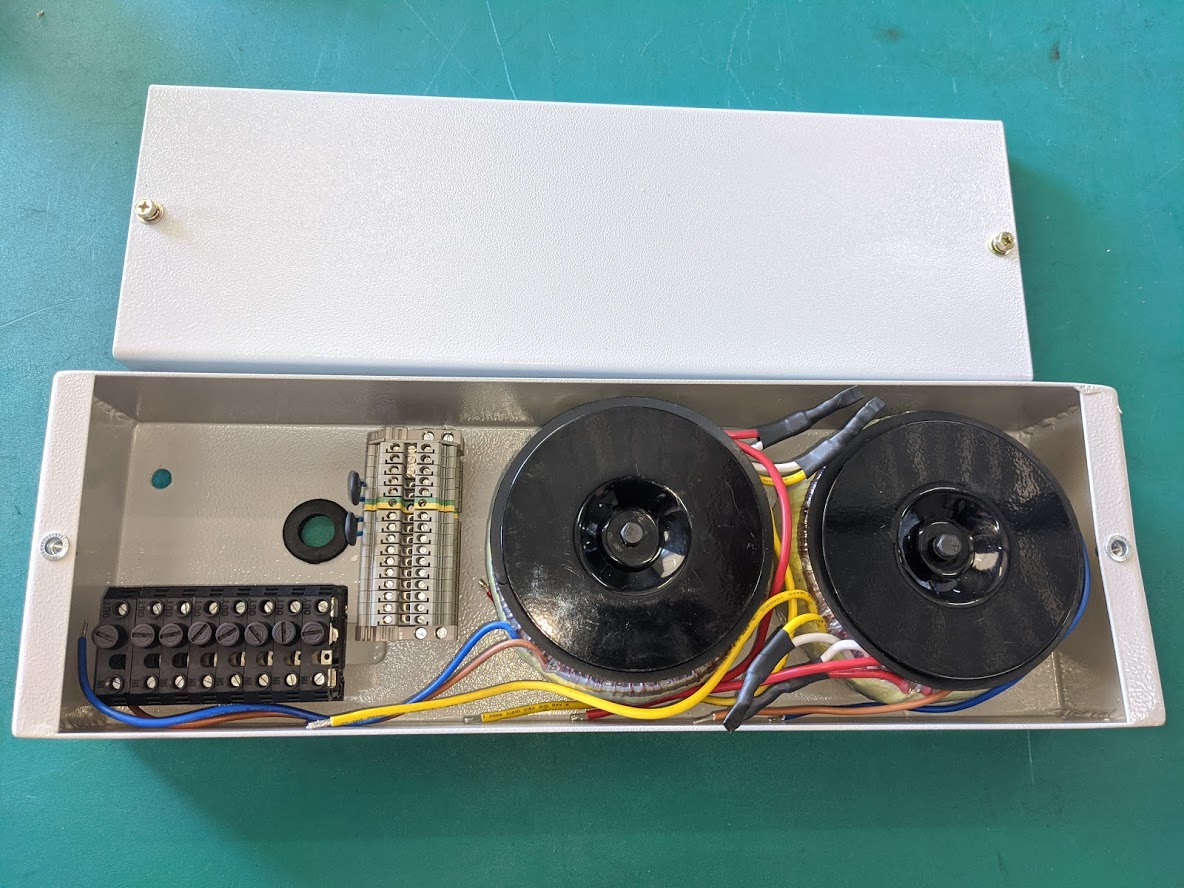

Finally this afternoon, I got the wiring pretty much done and I'm hoping my mate Chris will have time to give me a hand to refit the control box to the table tomorrow.

This box weighs about 17kg now. The wiring is just temporary and I'll have to disassemble it before it all comes together.

But finally, we have power lights on the Lam drivers! 90 volts wow!

A little bit tidier now

Just in time to becasue these arrived today as well

A NEMA 24 mounting bracket is also here so I can upgrade my Z axis with a Sanyo Denki motor. But to do that, I need my table back working again as I have to design and cut a mount for it.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

well rodw since you took the the time to check out my machine I decided to reply in kind. That plasma table looks fantastic . Well done.

Well we Toyota drivers have to stick together regardless of where we are in the world! I'd like to think this thread will get interesting again!

Finally this afternoon, I got the wiring pretty much done and I'm hoping my mate Chris will have time to give me a hand to refit the control box to the table tomorrow.

This box weighs about 17kg now. The wiring is just temporary and I'll have to disassemble it before it all comes together.

But finally, we have power lights on the Lam drivers! 90 volts wow!

A little bit tidier now

Just in time to becasue these arrived today as well

A NEMA 24 mounting bracket is also here so I can upgrade my Z axis with a Sanyo Denki motor. But to do that, I need my table back working again as I have to design and cut a mount for it.

Attachments:

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

02 Jul 2020 09:04 #173386

by thefabricator03

Replied by thefabricator03 on topic Rods "Spaceship" Scratch built Plasma Cutter build

What are the blue spade connectors on the back of the drives for? Earthing?

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

02 Jul 2020 09:13 #173387

by rodw

Yeh, originally, I used 5 pin connectors for the stepper cabling so I could pass the shield through on one pin and then I folded the shield back and added a male spade connector right at the stepper motors. Then they go up to an earth point just out of frame at the top right.

As it turned out, it was the right thing to do becasue the LAM's have a connector for the shield. Its a bit messy where the connectors are because I added piggy back spade connectors so I could terminate the shield on the driver and the enclosure. I'll try and remember to take a pic tomorow.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

What are the blue spade connectors on the back of the drives for? Earthing?

Yeh, originally, I used 5 pin connectors for the stepper cabling so I could pass the shield through on one pin and then I folded the shield back and added a male spade connector right at the stepper motors. Then they go up to an earth point just out of frame at the top right.

As it turned out, it was the right thing to do becasue the LAM's have a connector for the shield. Its a bit messy where the connectors are because I added piggy back spade connectors so I could terminate the shield on the driver and the enclosure. I'll try and remember to take a pic tomorow.

Please Log in or Create an account to join the conversation.

Time to create page: 0.217 seconds