Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

05 Jul 2020 08:04 #173650

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I had some troubles today getting my Lam drivers up and running. For some reason my old crappy Chinese motor on the Z axis refused to play with the LS1073a driver. I tried everything. The in desperation I swapped the drivers around and it worked perfectly on the larger DS1076a driver. Go figure.

Anyway, I still have to replace 3 motors in the coming days but on a quick test, it looks like we'll get away with at least 30 m/min (1200 in/min) and 5 m/sec/sec acceleration (200" / sec/sec) Thats 0.5 G's.

So this is what those figures look like:

And for the record, a good solid table like the spaceship, handles those sort of numbers in its stride. No stripped belts and no screaming balls!

Anyway, I still have to replace 3 motors in the coming days but on a quick test, it looks like we'll get away with at least 30 m/min (1200 in/min) and 5 m/sec/sec acceleration (200" / sec/sec) Thats 0.5 G's.

So this is what those figures look like:

And for the record, a good solid table like the spaceship, handles those sort of numbers in its stride. No stripped belts and no screaming balls!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

05 Jul 2020 08:57 #173651

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

A small-ish issue there, if you were jogging the machine on that video, set the Display and Traj section max_velocity at 25 to 50% more than each individual axis in the ini, that way it will not limit the X and Y axis speeds while jogging both of them at the same time.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

05 Jul 2020 09:07 #173653

by phillc54

Replied by phillc54 on topic Rods "Spaceship" Scratch built Plasma Cutter build

I always use me old mate Pythagoras to calculate that.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

05 Jul 2020 09:21 #173654

by rodw

Thats a cool idea Tommy. You might also notice the corners were rounded off with nice chamfers becasue I had no G64 settings. The poor old Chinese NEMA 34's couldn't keep up but the Sany Denki's seemed fine...

Pythagoras is a cool dude. I forgot about him for years but now I'm playing with Linuxcnc he keeps popping back into my life!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

A small-ish issue there, if you were jogging the machine on that video, set the Display and Traj section max_velocity at 25 to 50% more than each individual axis in the ini, that way it will not limit the X and Y axis speeds while jogging both of them at the same time.

Thats a cool idea Tommy. You might also notice the corners were rounded off with nice chamfers becasue I had no G64 settings. The poor old Chinese NEMA 34's couldn't keep up but the Sany Denki's seemed fine...

I always use me old mate Pythagoras to calculate that.

Pythagoras is a cool dude. I forgot about him for years but now I'm playing with Linuxcnc he keeps popping back into my life!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

05 Jul 2020 10:06 #173657

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

I said 25 to 50% as most of the time while testing the X and Y do not have the same max velocity, so i leave it at 50 to be safe.

After setting them both to the same velocity, 41.42% should do just fine.

After setting them both to the same velocity, 41.42% should do just fine.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

05 Jul 2020 14:24 #173670

by Clive S

Phill I didn't realise you was that old.

Replied by Clive S on topic Rods "Spaceship" Scratch built Plasma Cutter build

I always use me old mate Pythagoras to calculate that.

Phill I didn't realise you was that old.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jul 2020 00:34 #173701

by phillc54

HaHa, sometimes I feel that old...

Replied by phillc54 on topic Rods "Spaceship" Scratch built Plasma Cutter build

I always use me old mate Pythagoras to calculate that.

Phill I didn't realise you was that old.

HaHa, sometimes I feel that old...

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

12 Jul 2020 01:19 #174348

by thefabricator03

You see a lot of those aluminum extrusion tables wobble themselves apart at those speeds. I dont care what anyone says, a proper made steel table is hard to beat!

Replied by thefabricator03 on topic Rods "Spaceship" Scratch built Plasma Cutter build

And for the record, a good solid table like the spaceship, handles those sort of numbers in its stride. No stripped belts and no screaming balls!

You see a lot of those aluminum extrusion tables wobble themselves apart at those speeds. I dont care what anyone says, a proper made steel table is hard to beat!

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

12 Jul 2020 05:34 #174357

by rodw

I have to agree. The convenience of extrusions is vastly overshadowed by the additional cost!

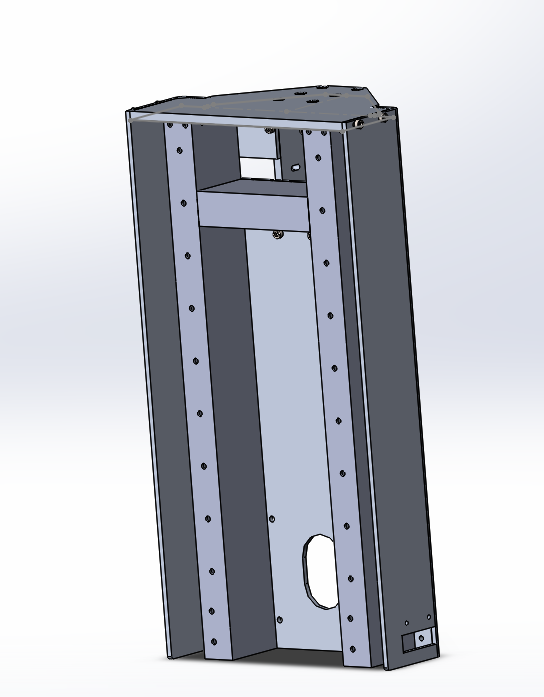

Anyway after another tuning session, I set the X axis to 36 m/min and 8 m/s^2 acceleration (just over 0.8 G). At these settings, it started to bounce around a bit and expose the spaceship's weakness. That is the 6mm folded aluminium gantry ends.

I always knew this was likely to be a problem but never knew how much wiring was going to be in there so I never designed any braces for it. So now I am working on designing a H shaped brace that will go full length top to bottom and pick up bolts through the top lid and the linear carriage mounts down the bottom. The crossbar of the H will be bolted to the gantry rail so it should stiffen it up enormously. I'm planning on using 80 x 40 x 3mm square section but might end up converting it to a U shaped section.

I'm not sure how much this idea will need to be butchered to allow for the wiring. But I think its a job for another weekend!

This weekend, I replaced the two Y axis motors

The new motors are the smaller ones with the pulleys on them. With shipping these cost about 4x what the other cheap ones are and are 7 amp vs the larges 4.2 amp motors. ANyway a bit of wight saving to offset the proposed braces.

Getting the pulley on worried me a bit. the Pulley had a 5mm keyway and the new motors had a 1/8" keyway. The old motors had a flat on the shaft and no keyway so I just used the provided grub screws. But this time with the forces I'm expecting I really thought I needed to use a keyway so I managed to machine a couple of stepped keys.

Anyway, I have not tried very hard, but this axis will easilly kept up with the 36 m/min and 8 ms^2 Acceleration after a couple of test runs. And that was only on 5 amps.

The Z axis motor is still to be replaced!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

You see a lot of those aluminum extrusion tables wobble themselves apart at those speeds. I dont care what anyone says, a proper made steel table is hard to beat!

I have to agree. The convenience of extrusions is vastly overshadowed by the additional cost!

Anyway after another tuning session, I set the X axis to 36 m/min and 8 m/s^2 acceleration (just over 0.8 G). At these settings, it started to bounce around a bit and expose the spaceship's weakness. That is the 6mm folded aluminium gantry ends.

I always knew this was likely to be a problem but never knew how much wiring was going to be in there so I never designed any braces for it. So now I am working on designing a H shaped brace that will go full length top to bottom and pick up bolts through the top lid and the linear carriage mounts down the bottom. The crossbar of the H will be bolted to the gantry rail so it should stiffen it up enormously. I'm planning on using 80 x 40 x 3mm square section but might end up converting it to a U shaped section.

I'm not sure how much this idea will need to be butchered to allow for the wiring. But I think its a job for another weekend!

This weekend, I replaced the two Y axis motors

The new motors are the smaller ones with the pulleys on them. With shipping these cost about 4x what the other cheap ones are and are 7 amp vs the larges 4.2 amp motors. ANyway a bit of wight saving to offset the proposed braces.

Getting the pulley on worried me a bit. the Pulley had a 5mm keyway and the new motors had a 1/8" keyway. The old motors had a flat on the shaft and no keyway so I just used the provided grub screws. But this time with the forces I'm expecting I really thought I needed to use a keyway so I managed to machine a couple of stepped keys.

Anyway, I have not tried very hard, but this axis will easilly kept up with the 36 m/min and 8 ms^2 Acceleration after a couple of test runs. And that was only on 5 amps.

The Z axis motor is still to be replaced!

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

25 Jul 2020 06:21 - 25 Jul 2020 06:22 #175710

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I learnt again the value of walking away when things go wrong today.

I've still had my machine apart with no water in the pan because during the week I hired a scissor lift had an electrician in to add a fair bit of wiring and some high bay lights. I wanted to be able to wheel the table around so every cable was disconnected. I think I must have the brightest workshop in the Southern Hemispehere now!

And I got rid a lot of powerboards and extension leads.

I needed to get some parts cut before the table goes into its final position and off its casters so I poured back in the pretty dirty water with additive in it that will have to do for a few days. So I set up for a cut and had no ArcOK which was quite annoying. So a couple of hours troubleshooting and making sure I had not broken something while I was upgrading my motors and drives.

Clearly, there was a fault tin the plasma cutter so I went home in disgust only to realise half way home that I had not bothered to connect the work clamp!

So I ordered some welding cable connectors so the work lead will plug into the table and I'll have another flylead coming off it to attach a clamp to the table. Thats something I've been meaning to do for a while!

The good news is that after rapiding to a new cut location with massively faster velocities and acceleration, the table stops wobbling during the probe event so I might get away with it for a while until I upgrade my gantries.

I remember now. I wanted to make the gantry out of 10mm folded plate but the laser cutter said they would crack when he folded them so I downsized to 6mm plate which I knew would be an issue.

I've still had my machine apart with no water in the pan because during the week I hired a scissor lift had an electrician in to add a fair bit of wiring and some high bay lights. I wanted to be able to wheel the table around so every cable was disconnected. I think I must have the brightest workshop in the Southern Hemispehere now!

And I got rid a lot of powerboards and extension leads.

I needed to get some parts cut before the table goes into its final position and off its casters so I poured back in the pretty dirty water with additive in it that will have to do for a few days. So I set up for a cut and had no ArcOK which was quite annoying. So a couple of hours troubleshooting and making sure I had not broken something while I was upgrading my motors and drives.

Clearly, there was a fault tin the plasma cutter so I went home in disgust only to realise half way home that I had not bothered to connect the work clamp!

So I ordered some welding cable connectors so the work lead will plug into the table and I'll have another flylead coming off it to attach a clamp to the table. Thats something I've been meaning to do for a while!

The good news is that after rapiding to a new cut location with massively faster velocities and acceleration, the table stops wobbling during the probe event so I might get away with it for a while until I upgrade my gantries.

I remember now. I wanted to make the gantry out of 10mm folded plate but the laser cutter said they would crack when he folded them so I downsized to 6mm plate which I knew would be an issue.

Last edit: 25 Jul 2020 06:22 by rodw.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

Time to create page: 1.708 seconds