Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

02 Sep 2020 00:11 #180377

by rodw

No we don't. Its no longer relevant as the top punch and the bottom die are programmed into the Presstek NC controller via a touch screen. Then Presstek is calibrated to the top of the die. See icontrol.net.au/ for the software

Watch the videos on that site. The software runs on any windows PC. I think using it as a retrofit would transform your presses. it seems very powerful and highly productive, designed for a production workflow...

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Hi, Rodw.

Do you have the maintenance manual for your Amada to adjust the punch and die to compensate for difference in penetration?

I have here if you wantand can share it!

Where i work we have 2press breake from Amada, one i put one VFD to control the backgauge.

No we don't. Its no longer relevant as the top punch and the bottom die are programmed into the Presstek NC controller via a touch screen. Then Presstek is calibrated to the top of the die. See icontrol.net.au/ for the software

Watch the videos on that site. The software runs on any windows PC. I think using it as a retrofit would transform your presses. it seems very powerful and highly productive, designed for a production workflow...

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

02 Sep 2020 02:49 #180386

by Himarc3D

Replied by Himarc3D on topic Rods "Spaceship" Scratch built Plasma Cutter build

I think you misunderstood me because my english isnt good...

The machine you have i think just control the bottom pressure (patented by amada here in japan and worldwide, simple mechanism very, very efficient because its simple) new machine models you can control individual punchs pressure and open/close too individually. In Japan Amada ITS is called RG series.

drive.google.com/file/d/1ZEcO4WWsUvNtX2P...f4c/view?usp=sharing

check the technical manual at 18-3 section its about what im talking, but for small bend like the one you made in the video its indifferent but if you pretend to use the entire length maybe you need the proper calibration, if you check using the dial gauge and after that you cant make all punchs 0 (maybe its already 0 all) you can align the bottom center or just use the warraty and let who sold do it, its time consuming the calibration of bottom maybe who sold it can do it.

The machine you have i think just control the bottom pressure (patented by amada here in japan and worldwide, simple mechanism very, very efficient because its simple) new machine models you can control individual punchs pressure and open/close too individually. In Japan Amada ITS is called RG series.

drive.google.com/file/d/1ZEcO4WWsUvNtX2P...f4c/view?usp=sharing

check the technical manual at 18-3 section its about what im talking, but for small bend like the one you made in the video its indifferent but if you pretend to use the entire length maybe you need the proper calibration, if you check using the dial gauge and after that you cant make all punchs 0 (maybe its already 0 all) you can align the bottom center or just use the warraty and let who sold do it, its time consuming the calibration of bottom maybe who sold it can do it.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

02 Sep 2020 03:00 #180389

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Sorry, that was my misunderstanding. Yes I found that document, printed out and saved a copy. I did see that calibration diagram. I have not really used the machine to know if that calibration is out. And yes, what I folded was just some scrap material from a plasma job. Until I get that part recut and need to fold it, I won't really know. I think it will be rare for us to want to fold a part more than a single die block (835 mm) long.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

02 Sep 2020 03:21 #180391

by Himarc3D

Replied by Himarc3D on topic Rods "Spaceship" Scratch built Plasma Cutter build

No sorry. im very gratefull for you guys, really.

I think its nice to know if you can use all, who knows the future...if you get some customer that need some kind of ducts, heater or anything...just after you accept the job you find you cant make it after you give your word isnt nice, right.

we had this problem here using ITS 103 but we figured out, Amada support avoid touch old type machines...the technical staff come 2 times and didn't solved the problem, after we did it. They tried to sell new machine to us using the government subsidy...

I think its nice to know if you can use all, who knows the future...if you get some customer that need some kind of ducts, heater or anything...just after you accept the job you find you cant make it after you give your word isnt nice, right.

we had this problem here using ITS 103 but we figured out, Amada support avoid touch old type machines...the technical staff come 2 times and didn't solved the problem, after we did it. They tried to sell new machine to us using the government subsidy...

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

02 Sep 2020 04:23 #180393

by rodw

Funny, I bought this old machine with a government subsidy.

I'll remember to keep an eye on the calibration and go to the manual if we have problems.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

They tried to sell new machine to us using the government subsidy...

Funny, I bought this old machine with a government subsidy.

I'll remember to keep an eye on the calibration and go to the manual if we have problems.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

04 Sep 2020 11:53 #180666

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

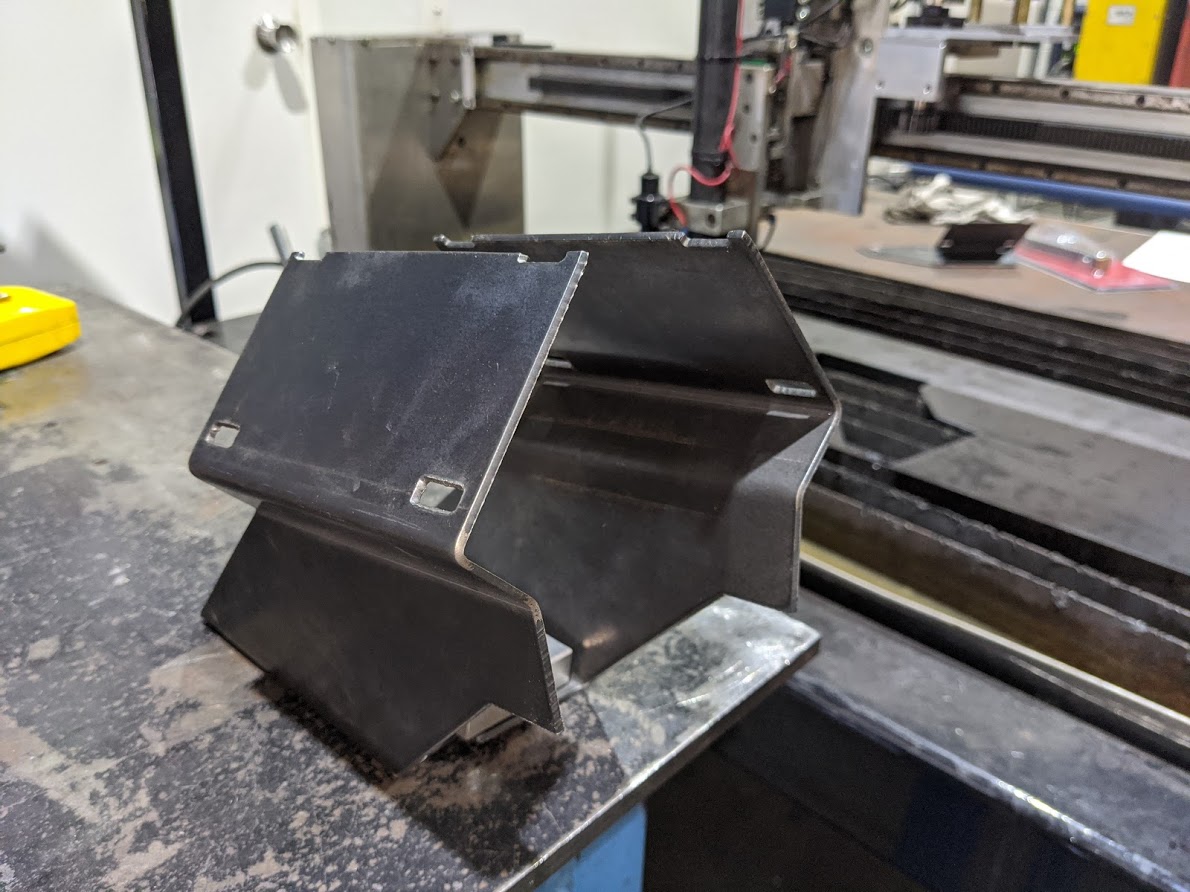

Well, finally did a real fold on my new press brake and as an added bonus, we had to design a part and plasma cut it

The things we do for our customers to deliver a quality product.. These are mounts for shock absorber remote reservoirs (cans).

We did not really like the manufacturer's mounts on our Hilux (think Tacoma if you are in the US). We were worried that they would be hit by the tyre on full lock.

So our revised mount moves the can higher and allows it to be mounted partly above the chassis rail by using an angled mount. We could not go too far over as there were other components in the road so it kinda did my head in when Dean told me where the can had to sit when I was designing the part.

If you look closely, you can see oscillations in the cuts near the corners and also inside the square slots. This is due to the massive increase in acceleration we have achieved (now 0.5 G) with our recent motor upgrade. Now we have a press brake, that opens up some new ways to stiffen up the gantry ends so watch this space!

The things we do for our customers to deliver a quality product.. These are mounts for shock absorber remote reservoirs (cans).

We did not really like the manufacturer's mounts on our Hilux (think Tacoma if you are in the US). We were worried that they would be hit by the tyre on full lock.

So our revised mount moves the can higher and allows it to be mounted partly above the chassis rail by using an angled mount. We could not go too far over as there were other components in the road so it kinda did my head in when Dean told me where the can had to sit when I was designing the part.

If you look closely, you can see oscillations in the cuts near the corners and also inside the square slots. This is due to the massive increase in acceleration we have achieved (now 0.5 G) with our recent motor upgrade. Now we have a press brake, that opens up some new ways to stiffen up the gantry ends so watch this space!

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

04 Sep 2020 16:41 #180706

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Yes we can, but we pretend we do not !If you look closely, you can see oscillations in the cuts near the corners and also inside the square slots.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

08 Sep 2020 11:42 - 08 Sep 2020 11:43 #181252

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Its been a long week. After folding those parts on Friday, because you guys were complaining about fingerprints on the old screen, on Saturday, I decided to upgrade the console using a neat little 15" touch screen monitor (Asus VT168H) and an Odroid H2+ (Please don't ask me which OS I installed).

But I had a wiring issue on the serial cable from the PC to the Ikon controller. I figured it would not be hard to fix and the day was done so I decided to come back the next day and switched the PC off. It immediately tried to do a firmware upgrade over the serial link. Then the LED on the controller was flashing madly so somehow it managed to talk to the controller and stuff it totally. Come Monday morning it was still stuck on the same screen so I called the technician and he came around at 7:00am this morning and soon sorted it out. What awesome service!

So i'm actually impressed with how they mounted the monitor and hid all the messy cables in a cabinet, I'm going to copy their idea eventually as I have been planning on doing something like this for a long time....

I've ordered a SMC bulkhead cable so once it turns up, I'm going to mount the wifi antenna on the top of the case instead of hidden in behind the monitor mount.

But I had a wiring issue on the serial cable from the PC to the Ikon controller. I figured it would not be hard to fix and the day was done so I decided to come back the next day and switched the PC off. It immediately tried to do a firmware upgrade over the serial link. Then the LED on the controller was flashing madly so somehow it managed to talk to the controller and stuff it totally. Come Monday morning it was still stuck on the same screen so I called the technician and he came around at 7:00am this morning and soon sorted it out. What awesome service!

So i'm actually impressed with how they mounted the monitor and hid all the messy cables in a cabinet, I'm going to copy their idea eventually as I have been planning on doing something like this for a long time....

I've ordered a SMC bulkhead cable so once it turns up, I'm going to mount the wifi antenna on the top of the case instead of hidden in behind the monitor mount.

Attachments:

Last edit: 08 Sep 2020 11:43 by rodw.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

08 Sep 2020 12:16 #181260

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nice !

I feel a draft going on, is there a window(s) open somewhere ?

I feel a draft going on, is there a window(s) open somewhere ?

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

08 Sep 2020 12:23 #181266

by rodw

Shhh! And to think that I blew Linuxcnc off the Odroid and paid $100 for a Win10 license.

I have to say though that the Presstek Ikon control is very nice to use. Plus it totally hides the OS from view!

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nice !

I feel a draft going on, is there a window(s) open somewhere ?

Shhh! And to think that I blew Linuxcnc off the Odroid and paid $100 for a Win10 license.

I have to say though that the Presstek Ikon control is very nice to use. Plus it totally hides the OS from view!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.241 seconds