"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

Is a single rail on the with some bearings as runner wheels to provide some extra support an option?

Open to advice and education on this.

Thanks - James.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

Oh and if you go to my website, there is an email in the footer. I did round up that assembly for you this morning. Send me an email so I can share it with you from Google Drive.

Oops. go here www.vmn.com.au/

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21231

- Thank you received: 7249

I used a single 25mm HiWin rail and a single carriage on many machines, they are still in perfect working order despite the owners not cleaning them ever!

But if a spec of plasma dust gets inside it will lock the carriage, so a bit of care should be taken when installing the carriage to the rail.

As a general rule, mount the rail at the bottom of the gantry, use screws in all the holes on the rail, have the gantry at least 15 to 20CM above slats, make the Z axis have at least 15cm of movement as it comes handy for cutting designs on square tubes.

Plenty of info here:

forum.linuxcnc.org/plasma-laser/35349-cn...fo-and-guide?start=0

forum.linuxcnc.org/plasma-laser/38974-di...rything-in-one-place

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

JT - re the axis being perpendicular to each other I guess other than being careful on construction that next part is getting the racking on the X under control. Dual motors and independent homing with adjustable home reference points being key to that exercise?

Sounds like a good plan to me.

JT

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

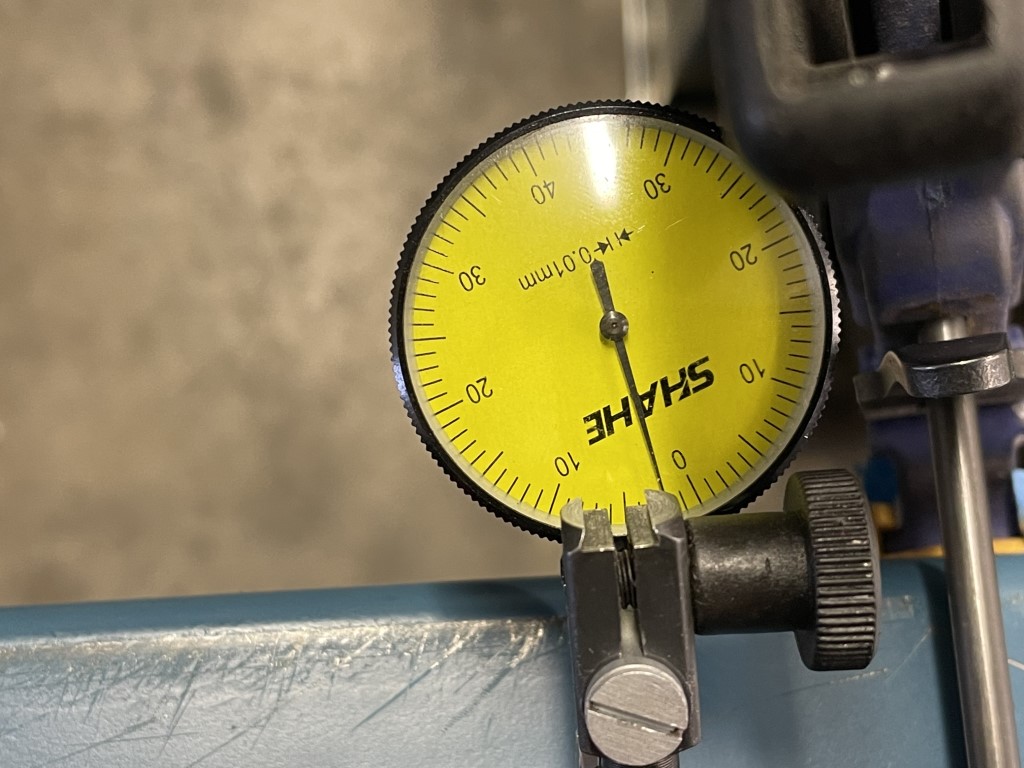

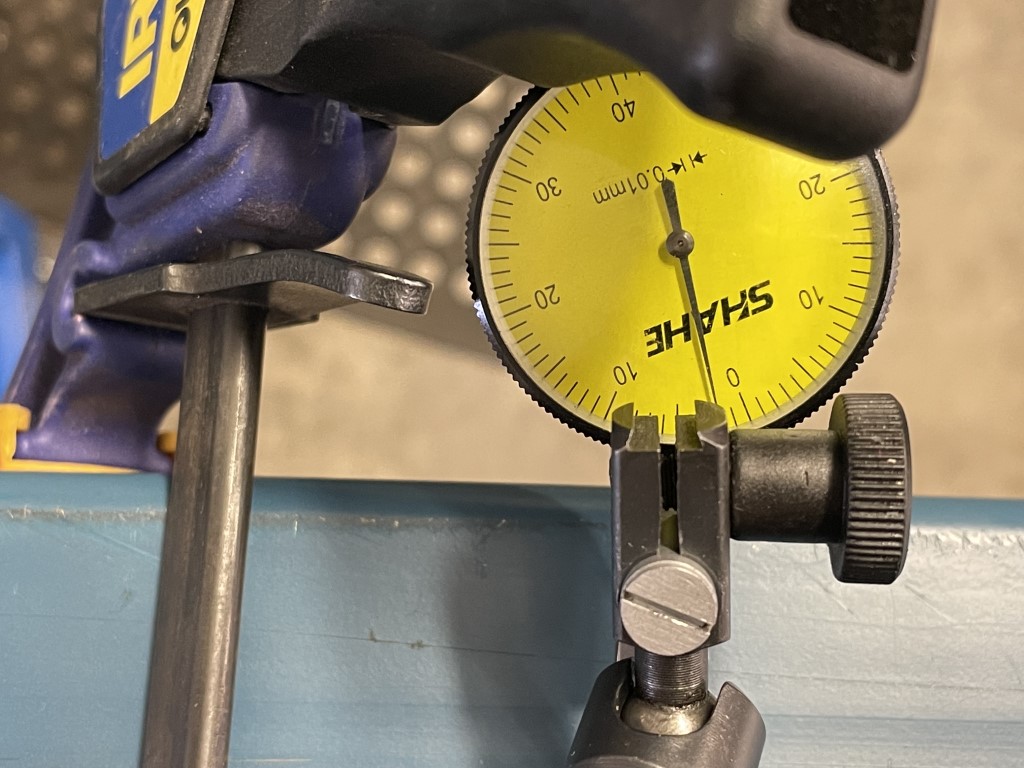

Mounted rail

An alignment bracket

Checking how accurate it is to top of rail

Setting middle of rail to zero as reference point

Right then Left tavel check. Pretty good at 0.02mm from zero. In sweeping across the length and bearing in mind this is hot rolled steel with primer on it there is 0.05 to 0.06 of variation. I would say that is pretty dang good given how this is all being put together.

I think a pretty good start to getting these rails lined up and ultimately in place.

Cheers - James.

Attachments:

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

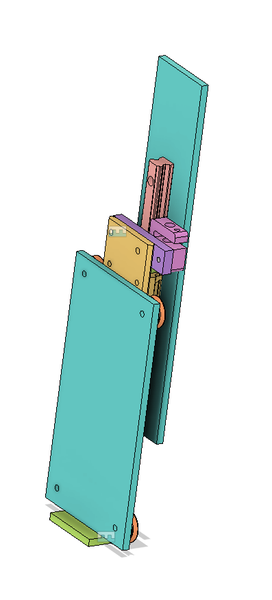

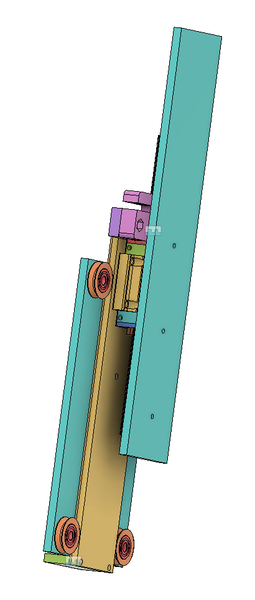

Attachments:

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

Looks like it's really coming along now

Cant wait to see the gantry on and how you go with the z axis

Cheers

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21231

- Thank you received: 7249

forum.linuxcnc.org/show-your-stuff/38547...plasma-build?start=0

Please Log in or Create an account to join the conversation.