"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

25 Jul 2021 00:22 #215826

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Looks good but from my experience I would swap the striker plate position with the switch position. I had no end of issues with reliable wiring when the switch was allowed to move...

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

25 Jul 2021 01:17 #215830

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

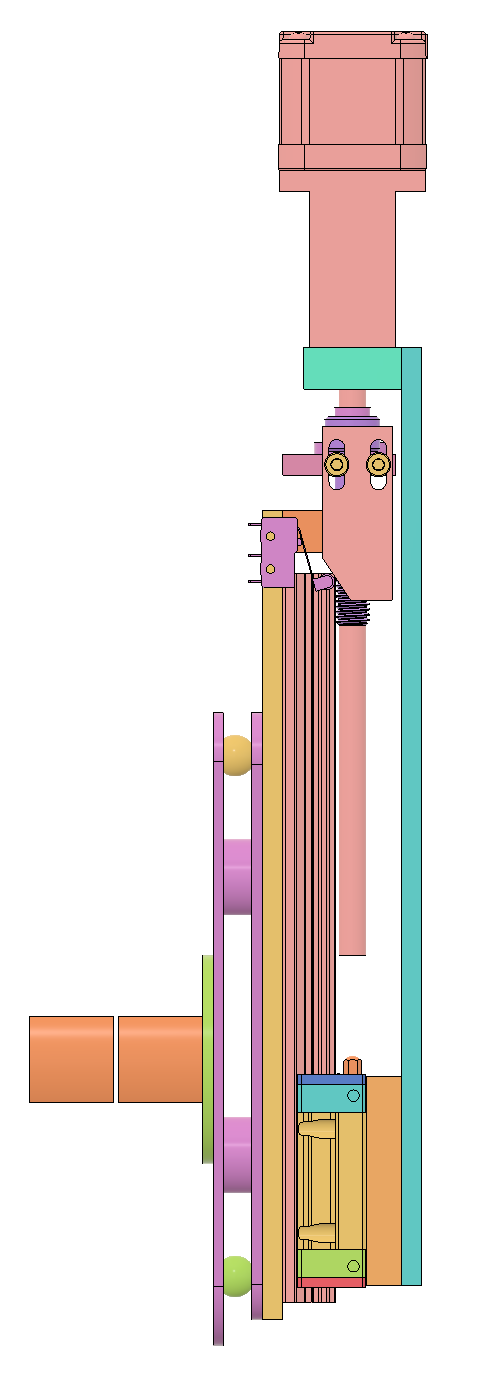

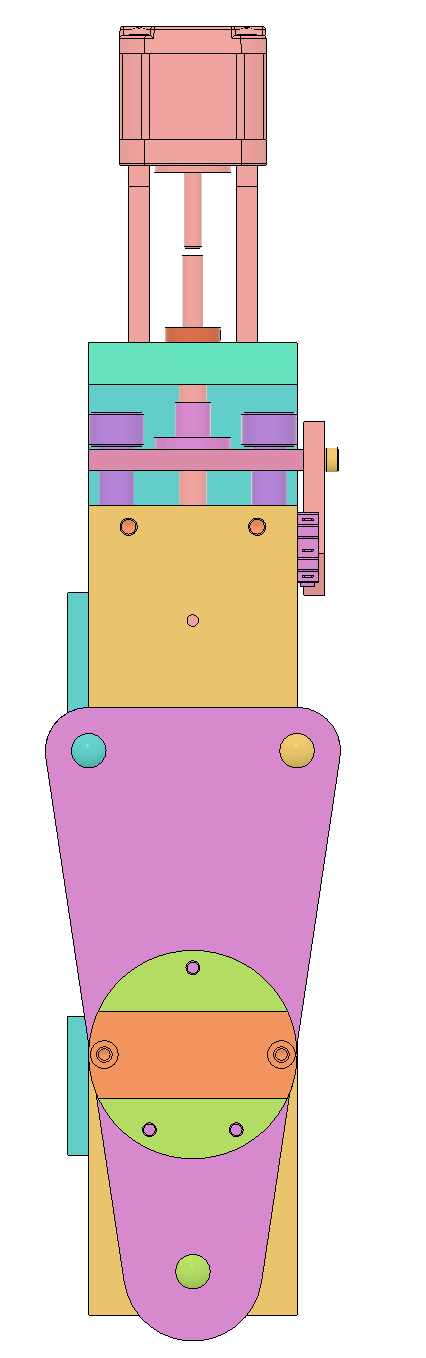

Rod - hmmm might need some more explanation. Unless I am missing it I'm sure the Z limit switch is non moving and for the floating switch it has to move.

I did deliberately swap the rail/truck positioning around. The truck is now the fixed mounting point and the rail is on the moving part. Essentially a linear rail version of Tommy's linear rod concept.

Cheers - J.

I did deliberately swap the rail/truck positioning around. The truck is now the fixed mounting point and the rail is on the moving part. Essentially a linear rail version of Tommy's linear rod concept.

Cheers - J.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

25 Jul 2021 07:10 #215840

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Sounds like I was the one missing something!Rod - hmmm might need some more explanation. Unless I am missing it I'm sure the Z limit switch is non moving and for the floating switch it has to move.

I did deliberately swap the rail/truck positioning around. The truck is now the fixed mounting point and the rail is on the moving part. Essentially a linear rail version of Tommy's linear rod concept.

Cheers - J.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

26 Jul 2021 08:55 #215937

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

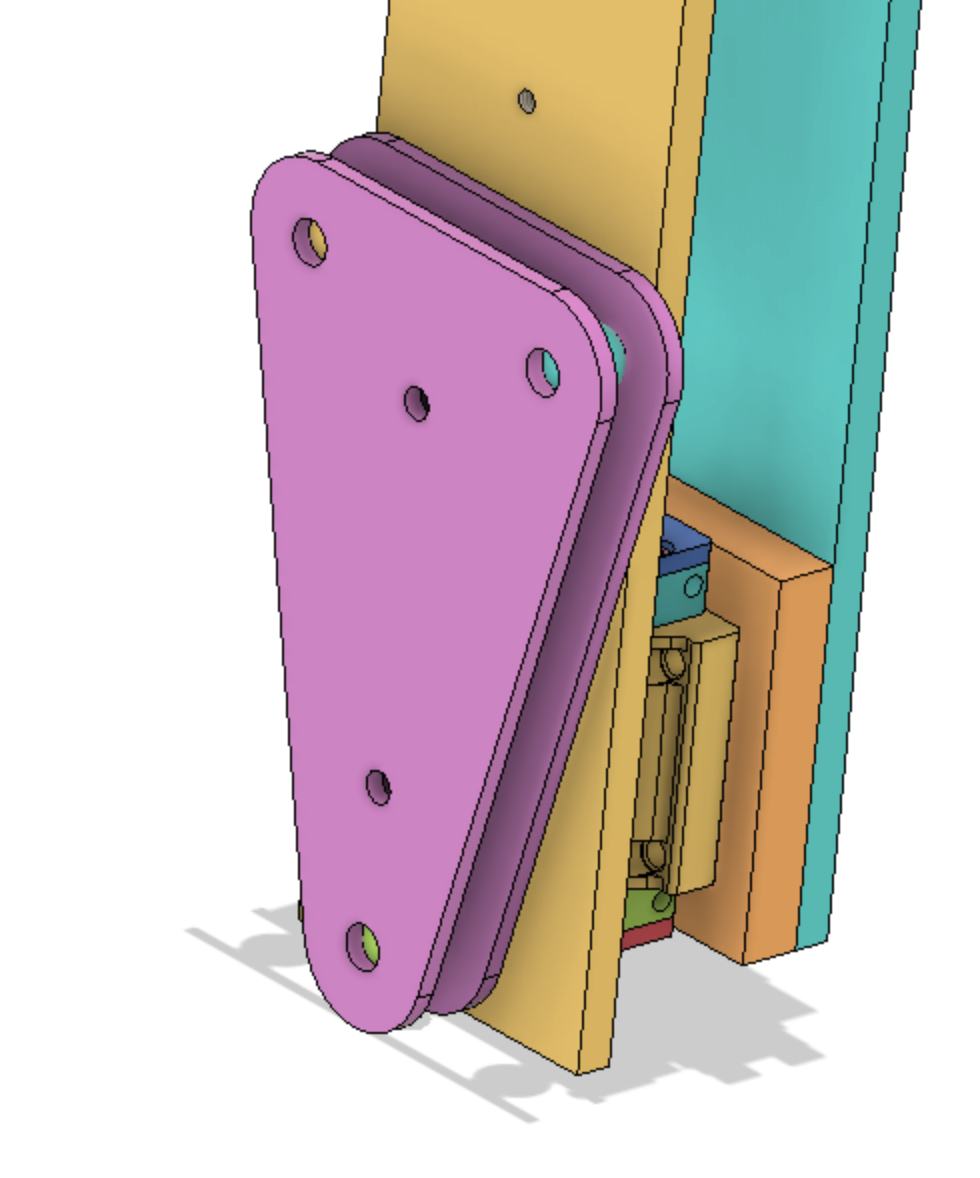

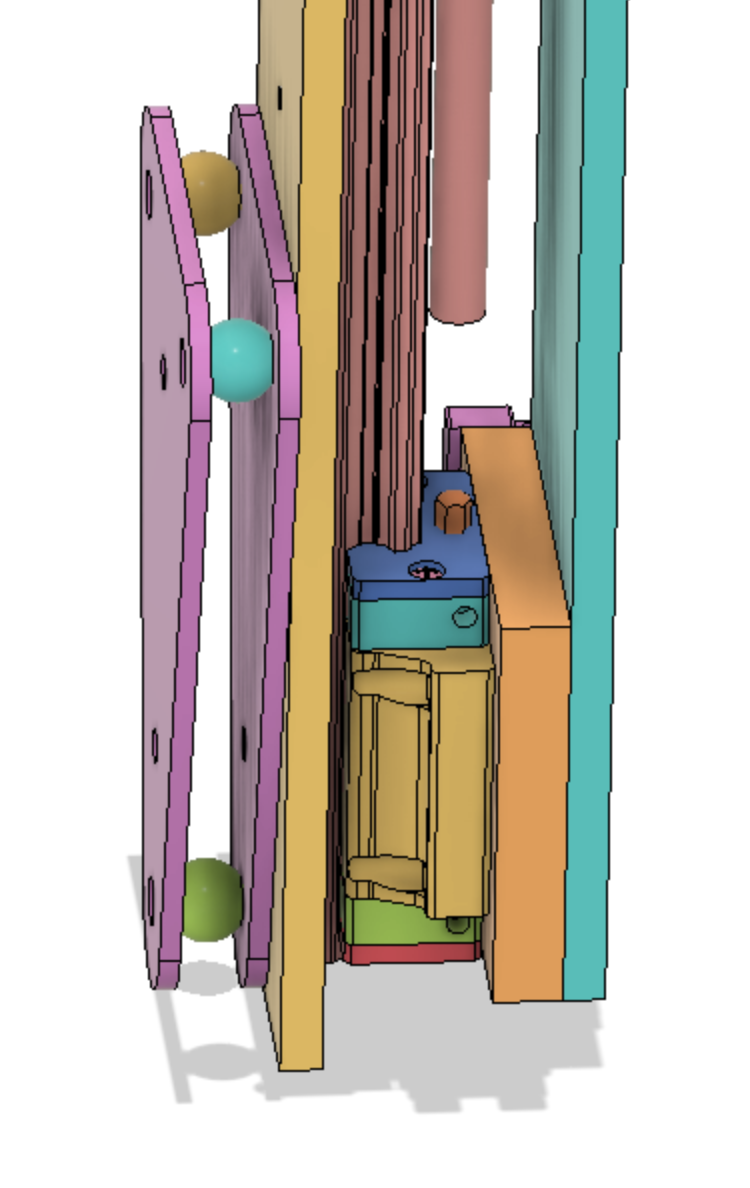

Initial concept for torch breakaway. I'm still working on dimensions and need to check what magnet sizes I can source which will influence the ball bearing sizes etc etc.

This isn't a new design and its concept is based on a design SeanP over on Spider Plasma created.

Anyway, thought I would post what I had at this point.

This isn't a new design and its concept is based on a design SeanP over on Spider Plasma created.

Anyway, thought I would post what I had at this point.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

26 Jul 2021 10:08 #215942

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

I like it!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21369

- Thank you received: 7288

26 Jul 2021 10:34 #215948

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

+1I like it!

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

30 Jul 2021 00:40 #216288

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

30 Jul 2021 03:13 - 30 Jul 2021 03:13 #216295

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

I think I might have a had a brain wave or brain fart. Will work on an idea and post it but I "think" I can simplify this and get easier reposioning for bevel cust.

Last edit: 30 Jul 2021 03:13 by Joco.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

30 Jul 2021 12:43 #216345

by BigJohnT

Replied by BigJohnT on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

The limit switch looks bullet proof now.

Looking good!

JT

Looking good!

JT

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

30 Jul 2021 14:43 #216351

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

I wonder how useful the fillet feature would be? Lets say you were cutting an end cap to weld onto a tube or square section.

How many setups would you have and how would you manage them?

If its not an end cap, there are plenty of ways to design a part to be welded without a fillet once you have a CNC plasma cutter at your disposal. eg. tab and slot construction. You can even cut the tabs shorter than the material thickness and weld from the back for a nice clean finish with no visible welds.

How many setups would you have and how would you manage them?

If its not an end cap, there are plenty of ways to design a part to be welded without a fillet once you have a CNC plasma cutter at your disposal. eg. tab and slot construction. You can even cut the tabs shorter than the material thickness and weld from the back for a nice clean finish with no visible welds.

Please Log in or Create an account to join the conversation.

Time to create page: 0.265 seconds