"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

24 Sep 2021 06:42 #221486

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

So a little update.

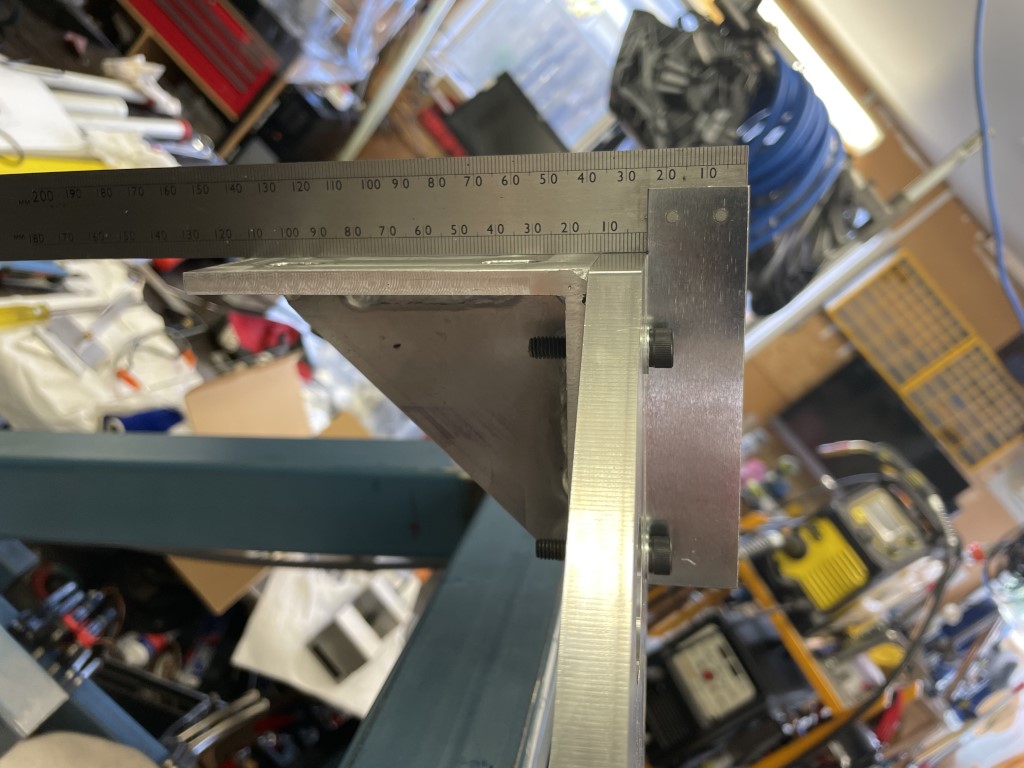

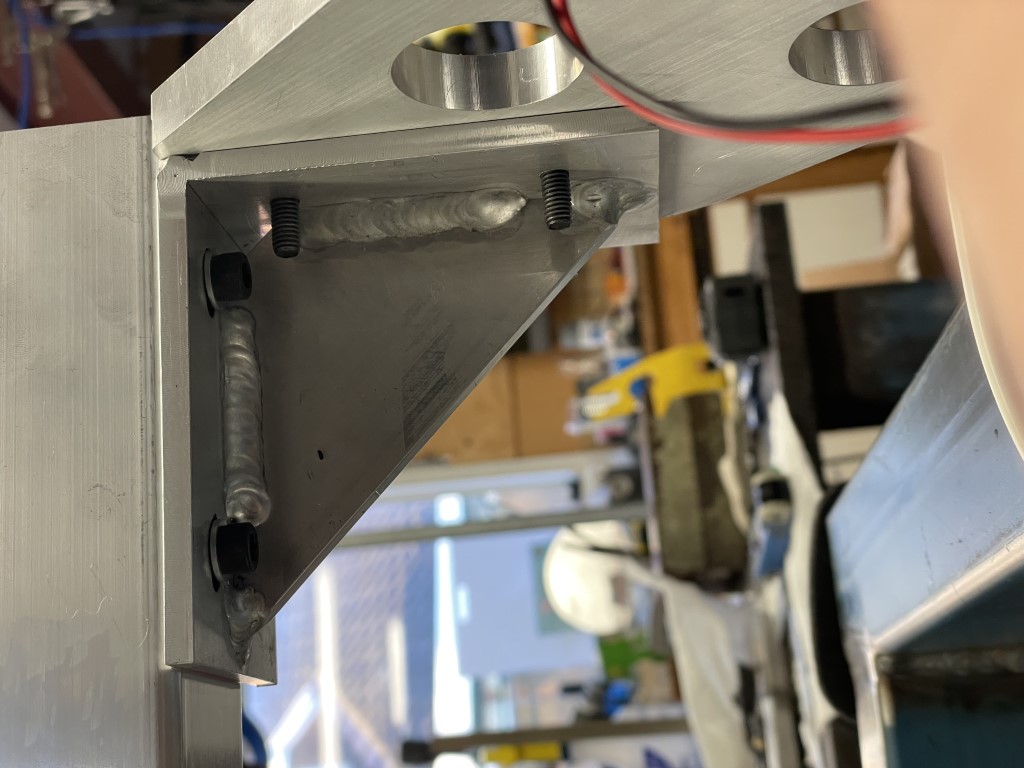

Got the brackets all welded up. Also went back and added some more weld in to get closer to what a proper fillet on 6mm should be.

Then after maching things square the first one mounted with a sqaure on it. Think its looking ok.

I couldn't resist just laying the raw gantry beam on the new mounts. Might need a little trim.

Unfortunately not going to get any progress this weekend as have to head north to parents. But the next thing of real note is going to be the Z/X assembly. Will get into that next week.

Cheers - James.

Got the brackets all welded up. Also went back and added some more weld in to get closer to what a proper fillet on 6mm should be.

Then after maching things square the first one mounted with a sqaure on it. Think its looking ok.

I couldn't resist just laying the raw gantry beam on the new mounts. Might need a little trim.

Unfortunately not going to get any progress this weekend as have to head north to parents. But the next thing of real note is going to be the Z/X assembly. Will get into that next week.

Cheers - James.

Attachments:

The following user(s) said Thank You: tommylight, RNJFAB

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

02 Oct 2021 07:05 #222000

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Update and design thinking.

Got the gantry cut, trimmed the ends square on the mill and drilled/tapped the mounting holes on mill at the same time. Need to get some shorter screws. These are getting a bit long. On the plus side it has proven that the brackets have turned out rather well.

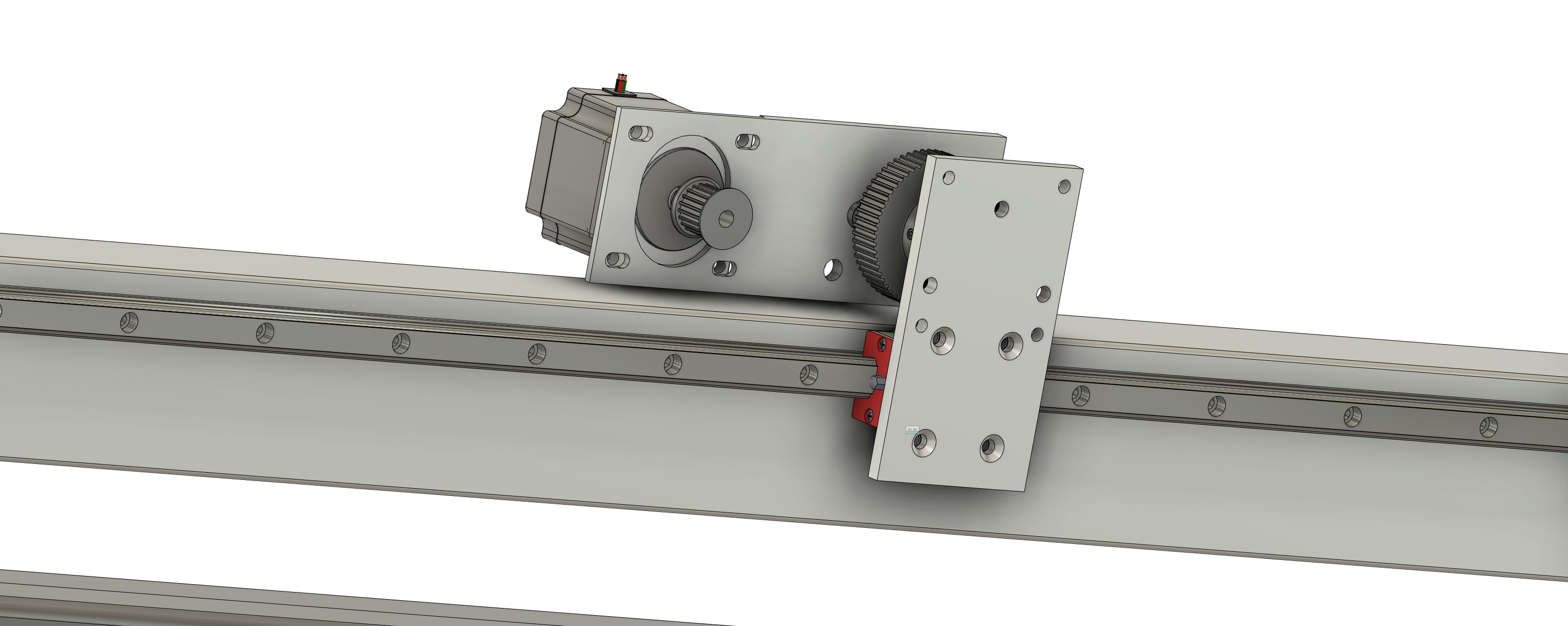

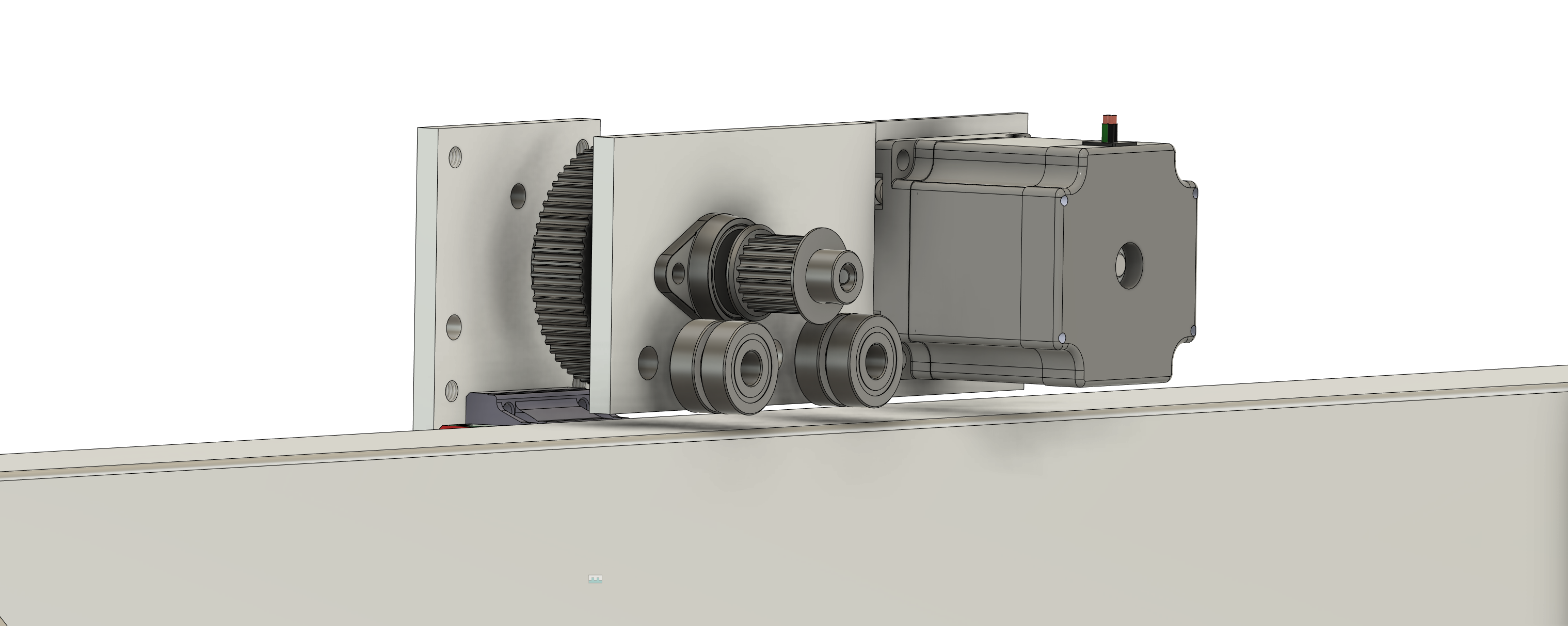

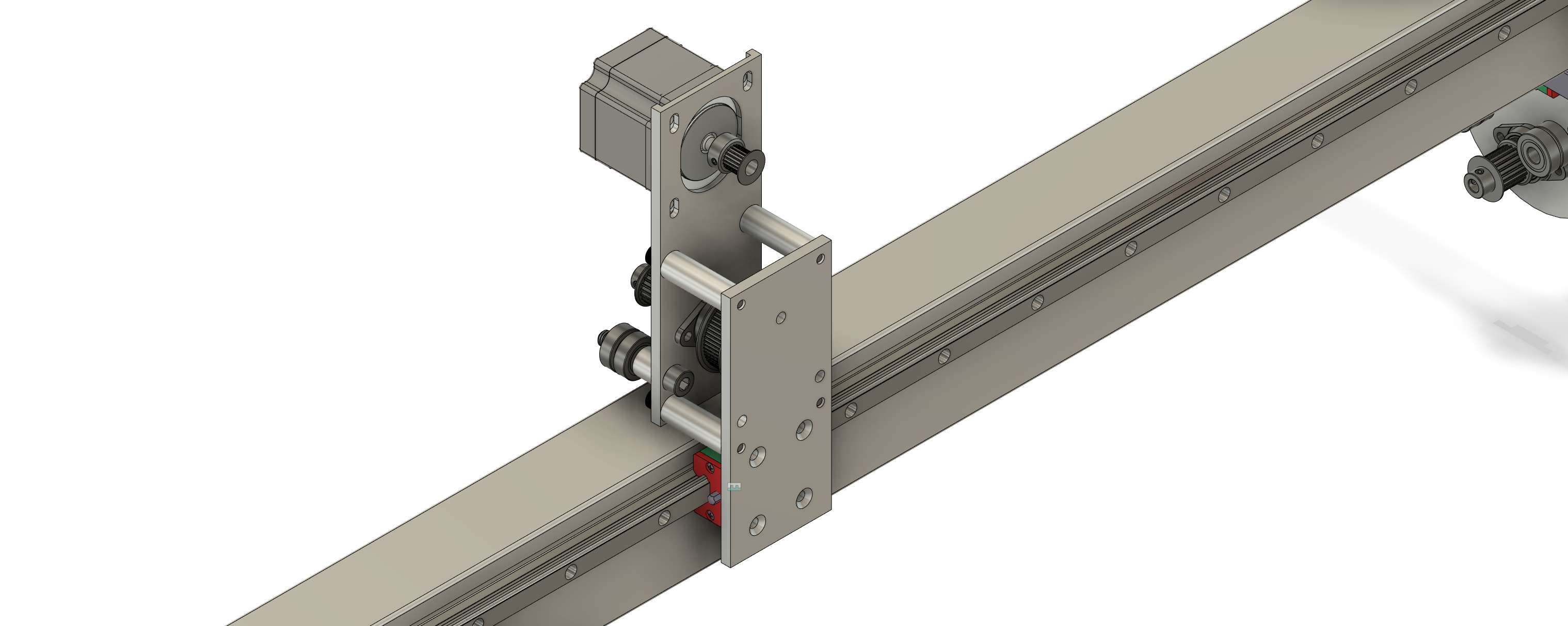

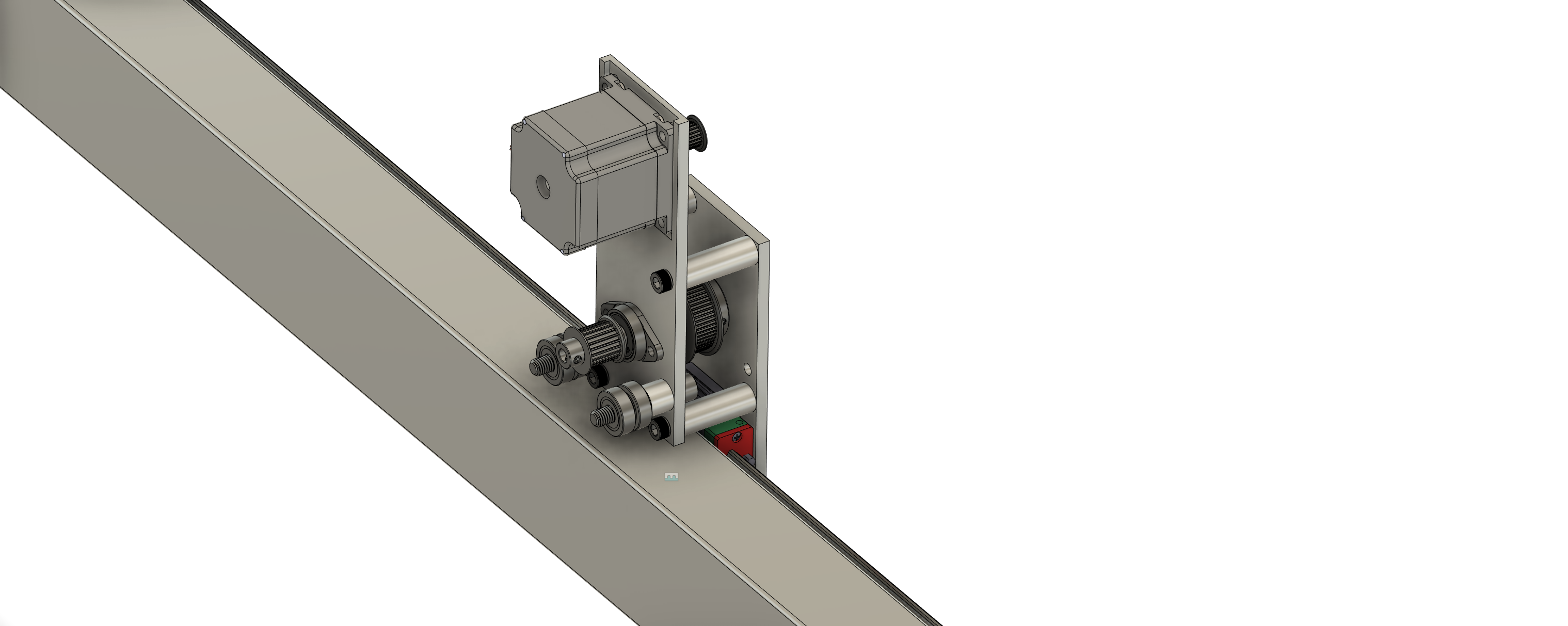

After seeing Tommylight's X axis belt design and it confirming some rough ideas I started converting things into CAD. This helps me get dimensions right first time and get a better feel for what the assembly will look like.

So here is an early idea for an X axis drive system using belts. Still rough and still debating how to secure things together. Obviously there is the potential to leave things in the current orientation or to move it 90deg shifting the motor higher above the gantry and in line with the Z axis.

Improvements/ideas welcome. Also any abservations on limitations and things to watch out for are welcome.

Cheers - James.

Got the gantry cut, trimmed the ends square on the mill and drilled/tapped the mounting holes on mill at the same time. Need to get some shorter screws. These are getting a bit long. On the plus side it has proven that the brackets have turned out rather well.

After seeing Tommylight's X axis belt design and it confirming some rough ideas I started converting things into CAD. This helps me get dimensions right first time and get a better feel for what the assembly will look like.

So here is an early idea for an X axis drive system using belts. Still rough and still debating how to secure things together. Obviously there is the potential to leave things in the current orientation or to move it 90deg shifting the motor higher above the gantry and in line with the Z axis.

Improvements/ideas welcome. Also any abservations on limitations and things to watch out for are welcome.

Cheers - James.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

02 Oct 2021 23:17 #222061

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21209

- Thank you received: 7245

02 Oct 2021 23:28 #222063

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

That works just fine and i like the idlers being very near the beam and from above so the belt is safer from accidental grabs. Also if later you want to add another belt glued to the beam and do "servo belt" style motion, it is already set up!

Do you have the pulleys already? I buy them from "ideaformer1" on ebay, never had issues and you can get 60T + 20T + 200mm GT2 belt for something like 5$ a set. Can't beat that!

Do you have the pulleys already? I buy them from "ideaformer1" on ebay, never had issues and you can get 60T + 20T + 200mm GT2 belt for something like 5$ a set. Can't beat that!

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

03 Oct 2021 06:06 #222073

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Have the pulleys and belt. Got a 4-lead (2mm pitch) 8mm leadscrew on the way for Z and still waiting for limit/home sensors.

Machine torch turned up this week so need to startt thinking about how to get that all working with the Cutskill 60.

Busy busy busy.

Cheers - J.

Machine torch turned up this week so need to startt thinking about how to get that all working with the Cutskill 60.

Busy busy busy.

Cheers - J.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

03 Oct 2021 10:03 #222087

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

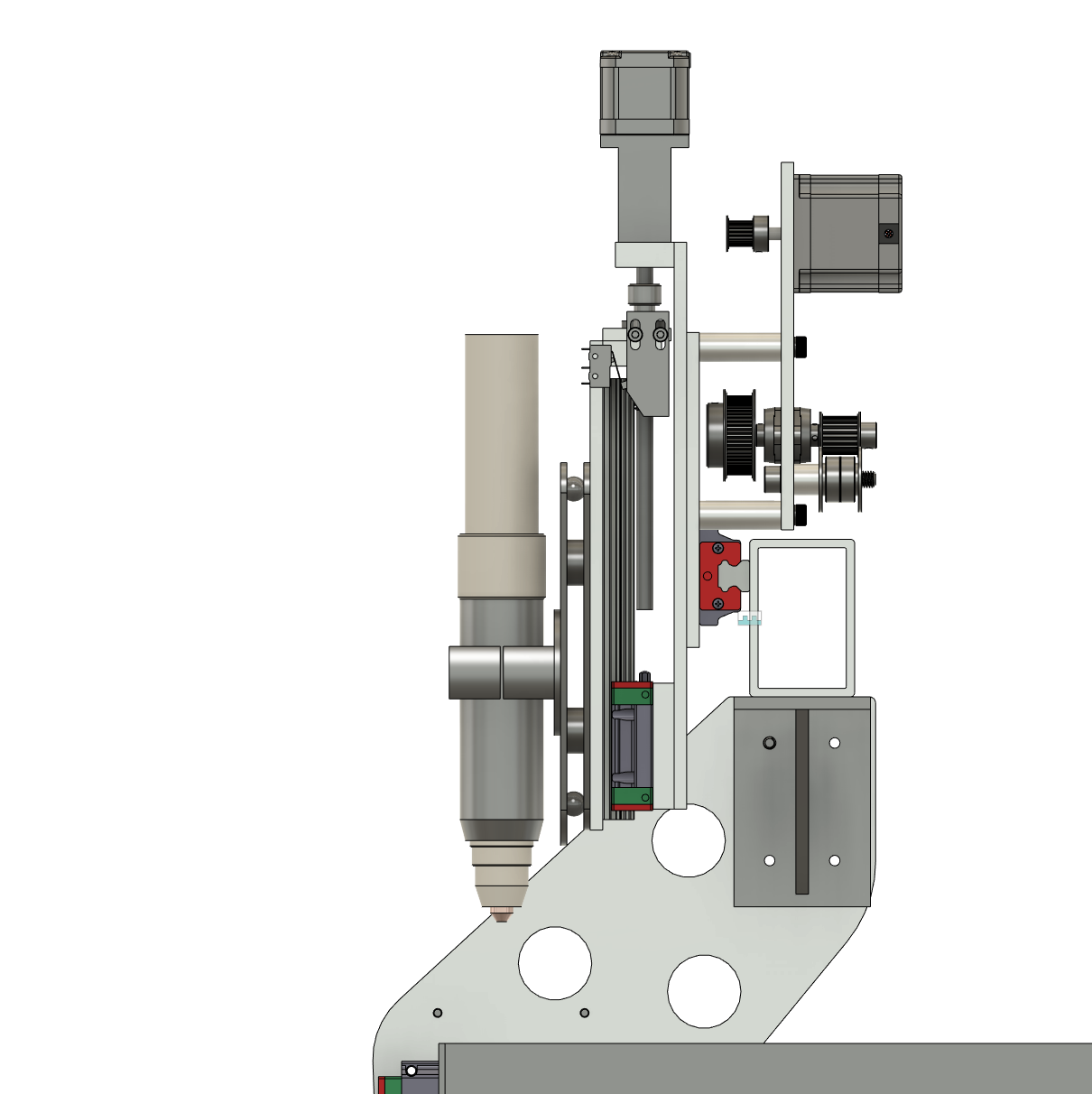

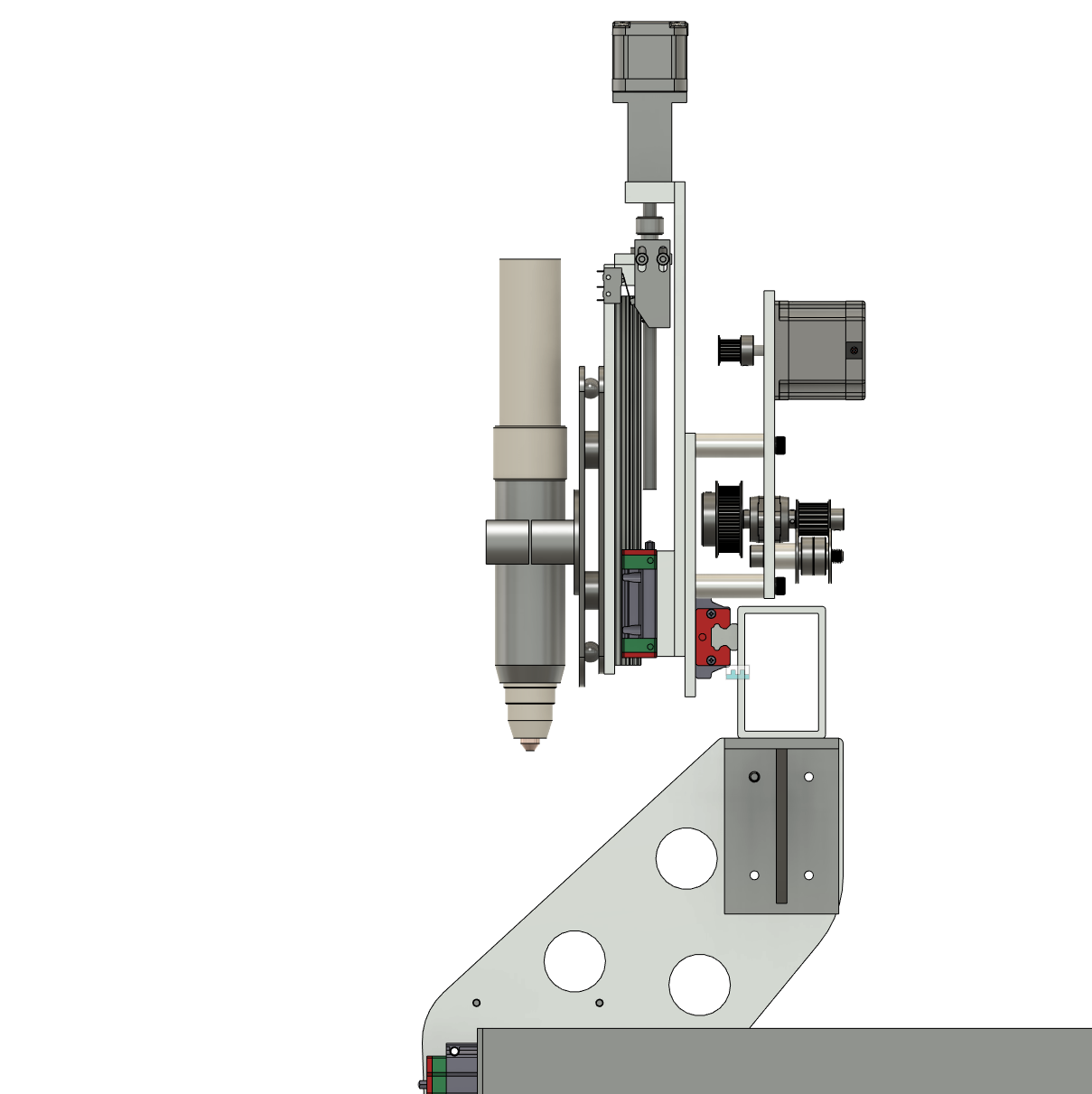

Been a busy CAD day as I flesh out the X and Z designs. Side views of the two mounting positions possible for standard sheet work or "tube" work up ~160mm diameter. Of course with the bracket system I could increase that in the future by creating new/taller brackets.

Standard mount.

High clearance mount

Standard mount.

High clearance mount

Attachments:

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

03 Oct 2021 18:32 - 03 Oct 2021 18:37 #222125

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

One question for those following along and any who have “been there, done that”, is the single 15mm linear rail with that single truck/bearing going to handle the loads in play during motion with that assembly on it?

As a reminder the gantry supports a cutting distance of 1260mm. Overall length of the beam is 1522mm.

Should I be considering changes to support 2 trucks? Or dual rails? Or am I starting to worry about nothing?

I would appreciate thoughts from anyone more familiar with the engineering and load performance of these sorts of things.

Cheers - James.

As a reminder the gantry supports a cutting distance of 1260mm. Overall length of the beam is 1522mm.

Should I be considering changes to support 2 trucks? Or dual rails? Or am I starting to worry about nothing?

I would appreciate thoughts from anyone more familiar with the engineering and load performance of these sorts of things.

Cheers - James.

Last edit: 03 Oct 2021 18:37 by Joco. Reason: Added gantry length data

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

03 Oct 2021 19:41 #222129

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Well, that is not hard too determine. The HGR specs (found on their dimensional diagrams) include torque specs for Mr, Mp and My. These are 0.15 or 0.17 kNm (150 or 170 Nm) depending on the direction of the rotation about the carriage.

Force from inertia = m x a

So say your assembly weighs 5 kg and your acceleration is 3 m/sec/sec, your inertial force equals 15 N

If you were to use CAD to define the centre of gravity of your assembly, you could define the rotational torque applied. Lets say your CoG was 100mm (0.1m) from the linear rail, the torque would be 15 * 0.1 = .15 Nm, about 1% of the HGR spec.

So at a guess, you have nothing to worry about

Force from inertia = m x a

So say your assembly weighs 5 kg and your acceleration is 3 m/sec/sec, your inertial force equals 15 N

If you were to use CAD to define the centre of gravity of your assembly, you could define the rotational torque applied. Lets say your CoG was 100mm (0.1m) from the linear rail, the torque would be 15 * 0.1 = .15 Nm, about 1% of the HGR spec.

So at a guess, you have nothing to worry about

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

03 Oct 2021 20:53 #222135

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Rod - THANK YOU! I'm a bit shite at the physic's stuff. And invariably get myself turned around and bent in half trying to work it out. Then look at the numbers and never quite trust them.

So with the independent review I will barrel on as planned. Only bunner is wont be in town until next weekend. But means I can plan out all my machining steps. Might do one last tweek to how the nema23 is mounted. It would ideally have a 6mm offset to the left so way more of the pully is fully engaged on the motor shaft. So a bolted overlapped plate will do that. Or I just try the existing design on that part and see how it goes. Can always remake/adjust it.

So with the independent review I will barrel on as planned. Only bunner is wont be in town until next weekend. But means I can plan out all my machining steps. Might do one last tweek to how the nema23 is mounted. It would ideally have a 6mm offset to the left so way more of the pully is fully engaged on the motor shaft. So a bolted overlapped plate will do that. Or I just try the existing design on that part and see how it goes. Can always remake/adjust it.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21209

- Thank you received: 7245

03 Oct 2021 21:17 #222142

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

HGR/HGH/HGW combo at 15mm will handle that easily but MGN15 will not be comfy.

www.hiwin.com/pdf/linear_guideways.pdf

Page 21, types and loads

Page 40 loads on all directions

www.hiwin.com/pdf/linear_guideways.pdf

Page 21, types and loads

Page 40 loads on all directions

Please Log in or Create an account to join the conversation.

Time to create page: 0.271 seconds