"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

30 Sep 2023 11:11 - 30 Sep 2023 11:12 #281919

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

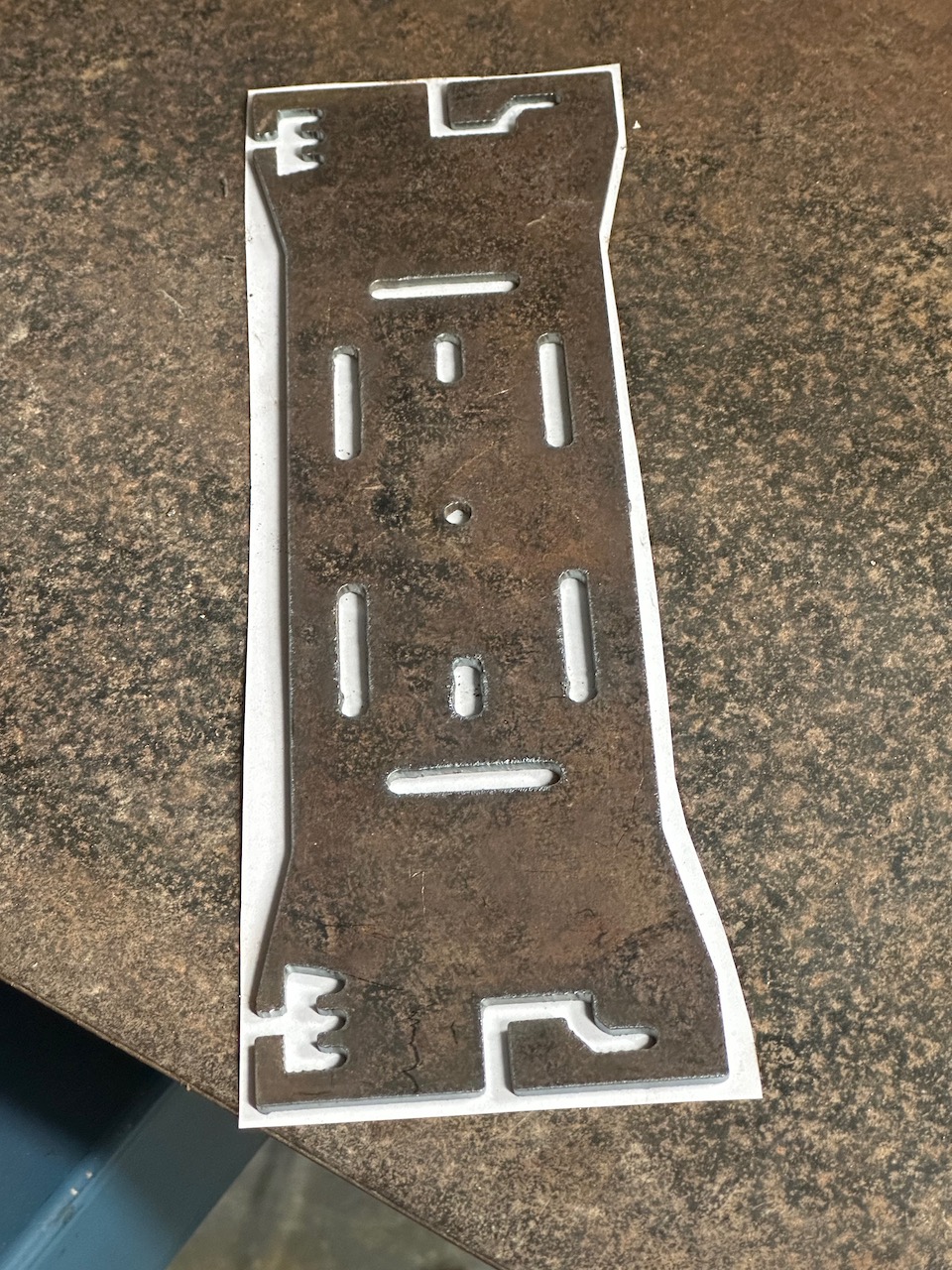

After a lot of trials and testing here is the first "complex" part cut. Still in 2mm mild stee, which is perfect for mount to be folded for my TYT MD-9600 radio.

And here is the video of the cutting process. Key details are:

Feed: 1700mm/min.

Amps: 40

Cut height: 1.5mm

Pierce height: 3.5mm

Material: 2mm mild steel sheet

Lead in: 4mm perpendeicular

Overcut: 1mm

Not saying these are optimal (e.g. overcut might be better to be -2mm with a perpendicular lead out)

Cheers - James.

And here is the video of the cutting process. Key details are:

Feed: 1700mm/min.

Amps: 40

Cut height: 1.5mm

Pierce height: 3.5mm

Material: 2mm mild steel sheet

Lead in: 4mm perpendeicular

Overcut: 1mm

Not saying these are optimal (e.g. overcut might be better to be -2mm with a perpendicular lead out)

Cheers - James.

Attachments:

Last edit: 30 Sep 2023 11:12 by Joco.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

01 Oct 2023 09:05 #281971

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

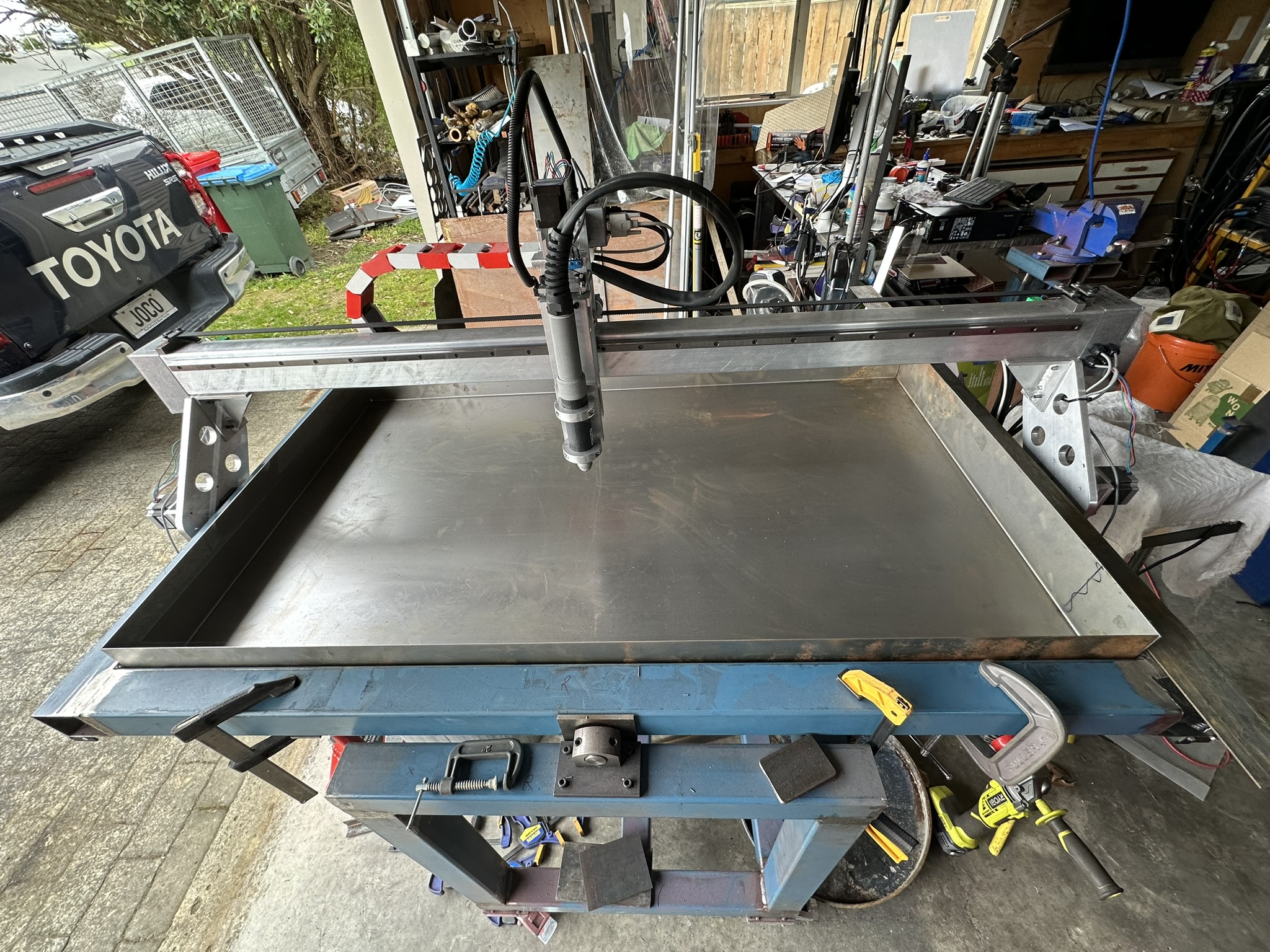

Manged to dig out some 6mm steel and try a test. Used the settings straigt out of a cut chart I found.

1200mm/min, 1.5mm cut height, 3.5mm pierce height, 45A, 4mm lead in and 1m overcut. Not a bad effort for a firsyt test cut on that thickness. But MAN the smoke! I'm going to pack things away a bit and get on to sorting the water table. The smoke/fumes are cracy.

1200mm/min, 1.5mm cut height, 3.5mm pierce height, 45A, 4mm lead in and 1m overcut. Not a bad effort for a firsyt test cut on that thickness. But MAN the smoke! I'm going to pack things away a bit and get on to sorting the water table. The smoke/fumes are cracy.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

07 Oct 2023 18:59 #282512

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

07 Oct 2023 20:18 #282513

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Looking niceeeeee!

Leave a bit of depth so you can cut under water and look at people watching it, makes for some strange looks when they figure out using electricity and air to make fire under water!

Just do not forget to air the nozzle after so it does not corrode.

Leave a bit of depth so you can cut under water and look at people watching it, makes for some strange looks when they figure out using electricity and air to make fire under water!

Just do not forget to air the nozzle after so it does not corrode.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

08 Oct 2023 04:15 - 08 Oct 2023 04:20 #282527

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Its 4" (103mm) deep. I planned it so I could put in a smaller (less high) set of slats for cutting under a little water. From what I could gather the under water method is most benifical for stainless. And then it will likely be no more than 3 or 4mm thick.

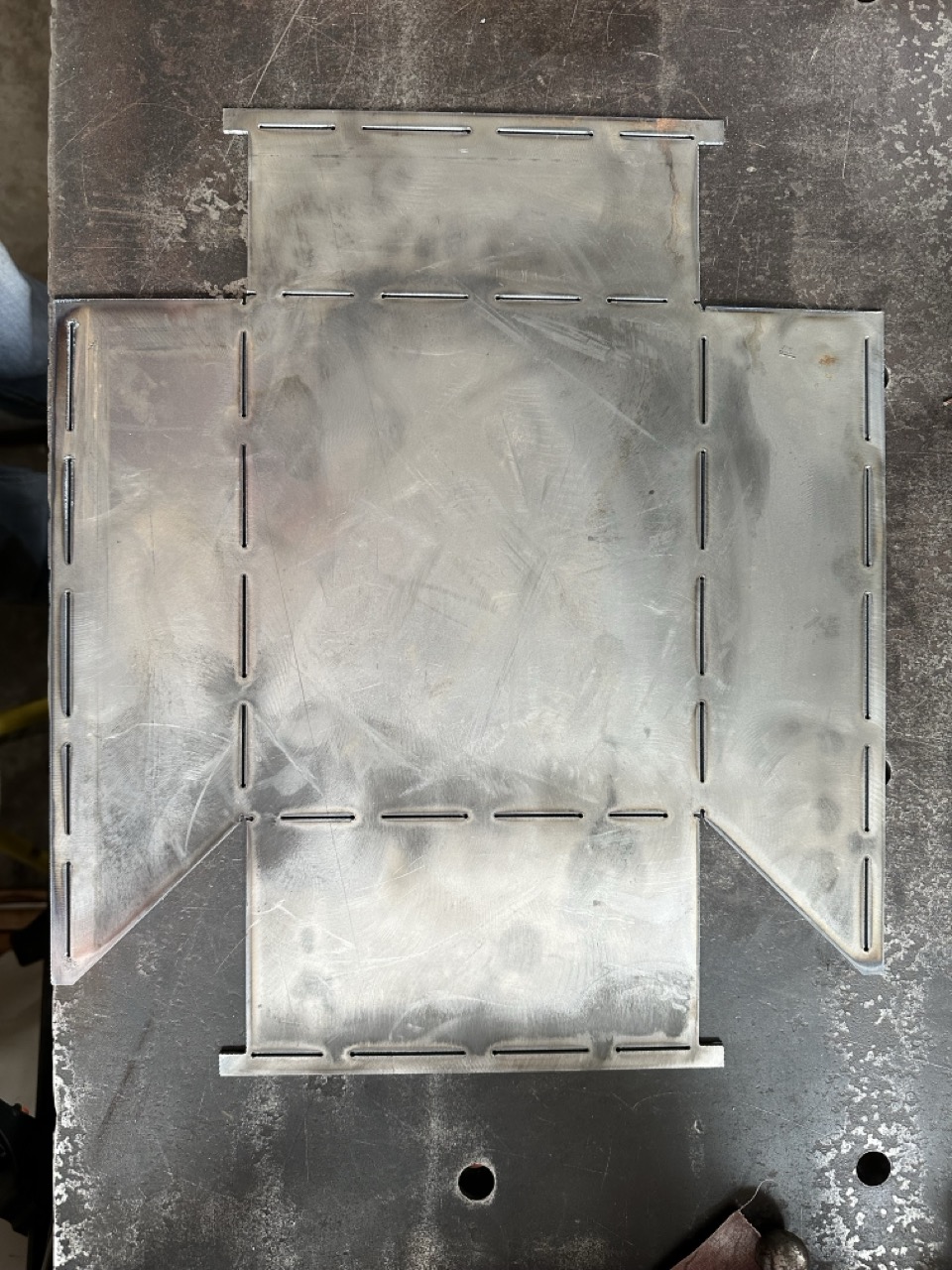

Today mess making video brought to you by plasma cutting without a water table. It's cutting out a shape to be folded into a sump insert for the water tray.

Today mess making video brought to you by plasma cutting without a water table. It's cutting out a shape to be folded into a sump insert for the water tray.

Attachments:

Last edit: 08 Oct 2023 04:20 by Joco.

The following user(s) said Thank You: tommylight, Clive S, rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11727

- Thank you received: 3972

08 Oct 2023 08:38 #282531

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Looks great, will be good to see it complete.

For 2mm steel, get in the habit of using a minumum flange of 20mm. One day you might be working with a press brake. Typical bend needs 10 x thickness for the V block. Nothing worse than designing a part you can't fold!

For 2mm steel, get in the habit of using a minumum flange of 20mm. One day you might be working with a press brake. Typical bend needs 10 x thickness for the V block. Nothing worse than designing a part you can't fold!

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Oct 2023 08:14 #282801

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

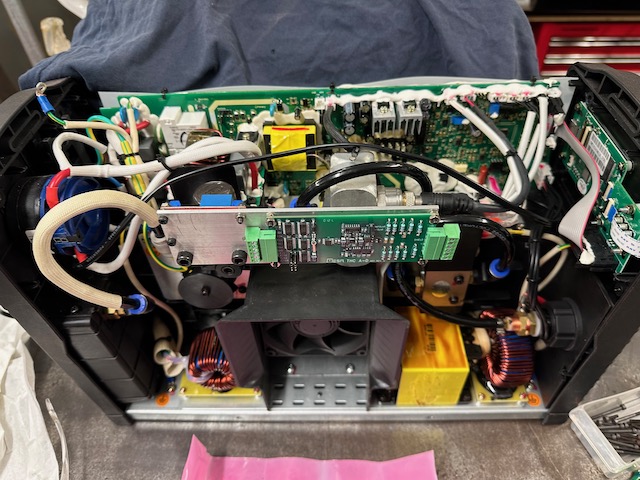

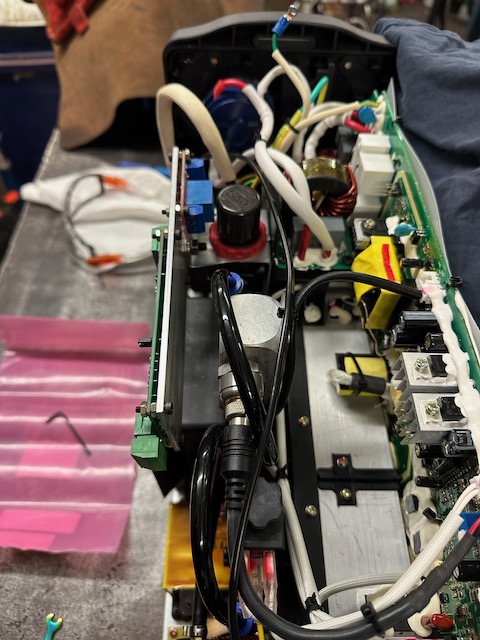

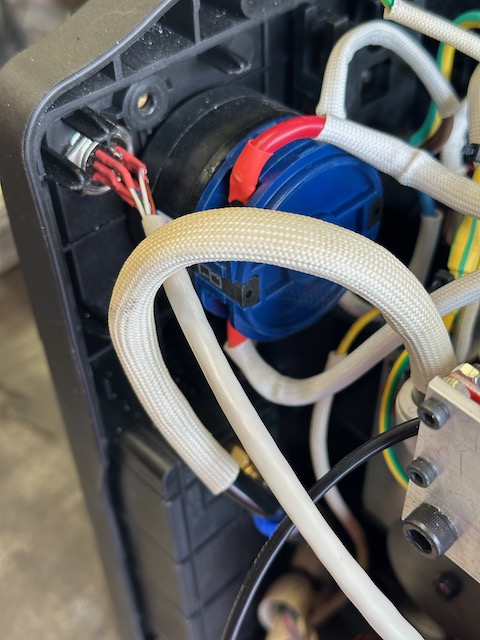

Have started the process of properly enabling the CIgweld Cutskill 60 for CNC control. Stage one is a mounting bracket that holds the THCAD and the relay for torch on/off control. Note that ArcOK is handled via a reed switch on the work return lead. This has proven to be operating very reliably.

Pic 1 shows the front view the THCAD-10 front and centre. The mounting is off the aire pressure control.

Pic 2 is looking down the length of the bracket. You can see the blue relay on the back side of the bracket.

Thanks - J.

Pic 1 shows the front view the THCAD-10 front and centre. The mounting is off the aire pressure control.

Pic 2 is looking down the length of the bracket. You can see the blue relay on the back side of the bracket.

Thanks - J.

Attachments:

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

13 Oct 2023 07:27 #282871

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

18 Oct 2023 07:00 - 18 Oct 2023 07:05 #283212

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Started doing some investigation into piercing strategies after some conversations on the topic. To start with how to leverage the wiggle leadin that sheetcam supports. Here are a couple of little videos that showed a dry run of (a) the wiggle under normal plasmac control and (b) using my custom plasmac with a new pin set to True.

(a) In the first part of the video you will see the normal probe sequence then a short wait, the torch drops to cut height then the wiggle and cuting morion continues.

(b)in the second half the video shows the probe then goes immediately into wiggle and then after ~3 wiggles the torch drops to cut height and continues on with cutting.

This second video is doing the actual cut with an active torch as shown by (b) above. This is 27A on 6mm mild steel in an attempt to mimic a thick steel pierce". First tome ever done on this setting so obviously tuning to be done on the number of wiggles. But it does prove that the process will execute on a live torch.

The next line of investigation will be in to the ramp leadin pierce that sheetcam supports.

Cheers - J.

(a) In the first part of the video you will see the normal probe sequence then a short wait, the torch drops to cut height then the wiggle and cuting morion continues.

(b)in the second half the video shows the probe then goes immediately into wiggle and then after ~3 wiggles the torch drops to cut height and continues on with cutting.

This second video is doing the actual cut with an active torch as shown by (b) above. This is 27A on 6mm mild steel in an attempt to mimic a thick steel pierce". First tome ever done on this setting so obviously tuning to be done on the number of wiggles. But it does prove that the process will execute on a live torch.

The next line of investigation will be in to the ramp leadin pierce that sheetcam supports.

Cheers - J.

Last edit: 18 Oct 2023 07:05 by Joco.

The following user(s) said Thank You: tommylight, Clive S, rodw, caretech

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

22 Oct 2023 18:54 #283524

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

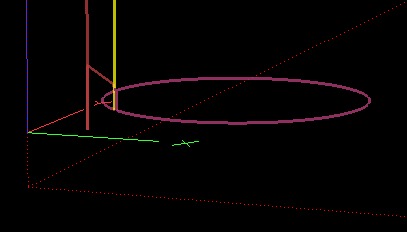

After reading the Hypertherm paper on moving pierce (ramp pierce) I have a little progress. I tried using

sheetcam generated code but it relies on having z gcode kept by qtplasmac. This also got messy as you need to touch Z0 off as material top. I decided I wanted to keep the “throw material on, align/zero xy home and go. So that meant doing all the Z ramp heigh change inside plasmac.

After quite a bit of code reading and scribbles I have an initial ramping pierce using the height stage transitions per hypertherm. Next will be the speeds and associated transition time points for them. That being Gouge, Intermediate/Crawl and Cut.

here is a sim pic of the ramp from pierce height to pierce end height then to cut height.

cheers - J

sheetcam generated code but it relies on having z gcode kept by qtplasmac. This also got messy as you need to touch Z0 off as material top. I decided I wanted to keep the “throw material on, align/zero xy home and go. So that meant doing all the Z ramp heigh change inside plasmac.

After quite a bit of code reading and scribbles I have an initial ramping pierce using the height stage transitions per hypertherm. Next will be the speeds and associated transition time points for them. That being Gouge, Intermediate/Crawl and Cut.

here is a sim pic of the ramp from pierce height to pierce end height then to cut height.

cheers - J

Attachments:

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.491 seconds