Z axis

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

26 May 2020 23:58 #169024

by tommylight

Replied by tommylight on topic Z axis

That does not affect anything, the machines will not move without receiving the ARCOK signal, just the wait time is a bit longer.

That certainly doesn't make things easy.

Twice i had plasma cutters that would wait longer when fired from the CPC port than from the torch trigger. One of them, an older Hypertherm wait about 3 to 4 seconds when triggered from the PC. Strange, but must be they use different timers as the PC part must be isolated from everything.The Torch On should behave exactly the same as the trigger on the hand torch.

All other ones i used do the same wait regardless from where they are triggered.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- jay1st

-

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

27 May 2020 14:26 #169131

by jay1st

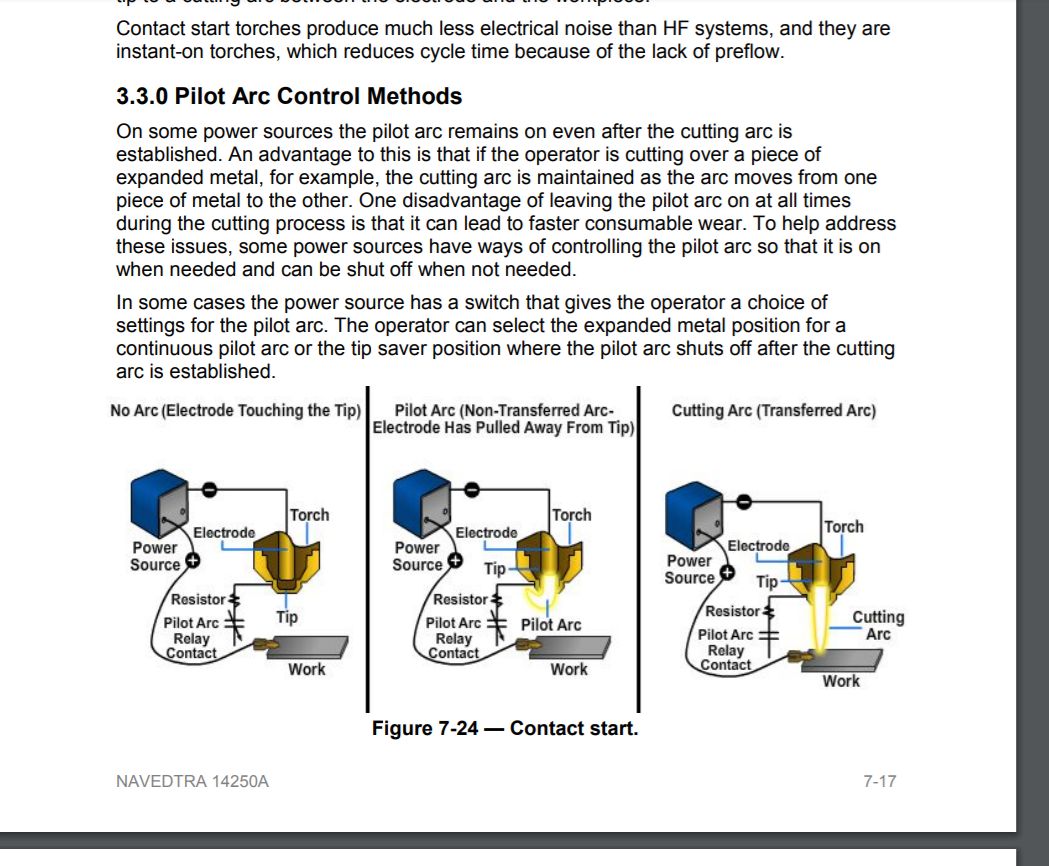

Nope, it can be pilot arc without HF.

There is still a ground wire coming back to the generator, and if the torch keeps firing over a gap without any metal around then it's a pilot arc system llike mine.

So the THCAD will never be able t detect any variation in voltage due to height change as the gap inside the torch never changes thus keeping the voltage more or less constant. See picture attached for the principle of pilotarc

Replied by jay1st on topic Z axis

jay1st I am aware that a plasma machine does not have to be HF to be a pilot arc. I will be the first to admit I should have not pinched pennies when I bought my plasma machine. Reading the link you provided it appears l have a very similar problem to what you had, but correct me if I am wrong your machine is a HF type right ? As I do not have a HF type plasma machine, your approach does not apply. I could be wrong wrong though.

Nope, it can be pilot arc without HF.

There is still a ground wire coming back to the generator, and if the torch keeps firing over a gap without any metal around then it's a pilot arc system llike mine.

So the THCAD will never be able t detect any variation in voltage due to height change as the gap inside the torch never changes thus keeping the voltage more or less constant. See picture attached for the principle of pilotarc

Attachments:

Please Log in or Create an account to join the conversation.

- motal2004

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 16

02 Jun 2020 00:54 - 02 Jun 2020 01:22 #169752

by motal2004

Replied by motal2004 on topic Z axis

Alright so after taking a couple days off. I’m back

I started from a very beginning.

Installed a Linux mint 19.2 Linuxcnc Build , pulled from the forum.

I build my working base configuration.

Moved to plasmaC

I build my asxis plasmaC configuration and when inputting required information I selected mode 1.

Next I began the adding of the THCAD lines in the hal file. But also comments out everything pertaining to mode 1 and switch to mode 0. I Homed machine imputes my offset and scale info

Resting voltage is ready zero

Opened up imperial_squares.ngc file a

Set my plasma cuttter to 30 amp at 110 ipm

Cutting Voltage was was 93 ish on screen .

Made lots of progress, couple questions

Machine stop after first cut and got “valid arc lost program is pause”

What do I do for that?

Second I’m 1/16 of an inc , 1.5875mm , on the small size off I measure the cut square. Do I go up or down on the axis tunning?

I started from a very beginning.

Installed a Linux mint 19.2 Linuxcnc Build , pulled from the forum.

I build my working base configuration.

Moved to plasmaC

I build my asxis plasmaC configuration and when inputting required information I selected mode 1.

Next I began the adding of the THCAD lines in the hal file. But also comments out everything pertaining to mode 1 and switch to mode 0. I Homed machine imputes my offset and scale info

Resting voltage is ready zero

Opened up imperial_squares.ngc file a

Set my plasma cuttter to 30 amp at 110 ipm

Cutting Voltage was was 93 ish on screen .

Made lots of progress, couple questions

Machine stop after first cut and got “valid arc lost program is pause”

What do I do for that?

Second I’m 1/16 of an inc , 1.5875mm , on the small size off I measure the cut square. Do I go up or down on the axis tunning?

Last edit: 02 Jun 2020 01:22 by motal2004.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

02 Jun 2020 04:11 #169764

by phillc54

Replied by phillc54 on topic Z axis

Have you done some probe tests to confirm the heights are correct?

Could the size difference be due to kerf width?

Could the size difference be due to kerf width?

Please Log in or Create an account to join the conversation.

- motal2004

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 16

02 Jun 2020 14:01 #169805

by motal2004

Replied by motal2004 on topic Z axis

I took a quick peak this before leaving for work this morning at My machine torch, it appears it is kicked in just a little bit, I’m thinking that’s where I am loosing my 1/16 in my cuts I will try correcting that tonight.

As far as for probe testing, I did hit the probe test button before my cuts yesterday. This morning I jog the z axis all the way to the bottom, hitting the sheet metals, I jog up 1 inch on screen, measure physically and it’s 1 inch , jogged 2 inches on screen and physically re measure and I’m getting what seems to be consistent accurate measurements when jogging the z axis.

At lunch I’m going to do some re reading the manual again. I might be missing something.

Last think to me it appears that the GUI configuration of axis move slower then gmoccapy. Is that just in my head?

As far as for probe testing, I did hit the probe test button before my cuts yesterday. This morning I jog the z axis all the way to the bottom, hitting the sheet metals, I jog up 1 inch on screen, measure physically and it’s 1 inch , jogged 2 inches on screen and physically re measure and I’m getting what seems to be consistent accurate measurements when jogging the z axis.

At lunch I’m going to do some re reading the manual again. I might be missing something.

Last think to me it appears that the GUI configuration of axis move slower then gmoccapy. Is that just in my head?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

02 Jun 2020 23:12 #169883

by phillc54

Replied by phillc54 on topic Z axis

Axis motion should be the same.

Please Log in or Create an account to join the conversation.

- motal2004

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 16

05 Jun 2020 00:07 #170182

by motal2004

Replied by motal2004 on topic Z axis

For imperial_circle ngc or imperial_square.ngc

When I cutting it will cut the first part but when It moves to second cut I get error message of “valid arc lost program is paused”

Any suggestions?

When I cutting it will cut the first part but when It moves to second cut I get error message of “valid arc lost program is paused”

Any suggestions?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

05 Jun 2020 00:20 #170186

by tommylight

Replied by tommylight on topic Z axis

Video, and hal scope trace of arc voltage, what mode are you using ?For imperial_circle ngc or imperial_square.ngc

When I cutting it will cut the first part but when It moves to second cut I get error message of “valid arc lost program is paused”

Any suggestions?

Please Log in or Create an account to join the conversation.

- motal2004

- Offline

- Premium Member

-

Less

More

- Posts: 150

- Thank you received: 16

09 Jun 2020 04:14 - 09 Jun 2020 04:18 #170751

by motal2004

Replied by motal2004 on topic Z axis

Mode 0

voltage is reading correctly cutting at about 123V

on on my test part i has 7 cuts, 6 circles and the outside cut. i have to hit pause bottom to moved on to the next cut.

I have videos that i'm trying to figure out how to up load. here is a link to them for now,

drive.google.com/drive/folders/1kC6XCTTn...V2GHv8h-?usp=sharing

quality of video is not best , sorry

voltage is reading correctly cutting at about 123V

on on my test part i has 7 cuts, 6 circles and the outside cut. i have to hit pause bottom to moved on to the next cut.

I have videos that i'm trying to figure out how to up load. here is a link to them for now,

drive.google.com/drive/folders/1kC6XCTTn...V2GHv8h-?usp=sharing

quality of video is not best , sorry

Last edit: 09 Jun 2020 04:18 by motal2004.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

09 Jun 2020 04:50 - 09 Jun 2020 04:51 #170752

by phillc54

Replied by phillc54 on topic Z axis

Access is denied to the video.

I thought you had a machine with Arc OK out.

I thought you had a machine with Arc OK out.

Last edit: 09 Jun 2020 04:51 by phillc54.

Please Log in or Create an account to join the conversation.

Time to create page: 0.182 seconds