Please Help - How to Configure a 5 Axis Head-Head

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

REMAP=M6 modalgroup=6 prolog=change_prolog ngc=psng_manual_change epilog=change_e

to this note the missing ending above:

REMAP=M6 modalgroup=6 prolog=change_prolog ngc=psng_manual_change epilog=change_epilog

Please Log in or Create an account to join the conversation.

- IronManDylan

- Offline

- Premium Member

-

- Posts: 151

- Thank you received: 22

Man, if you are ever in New Mexico or Texas, my family wants to cook you dinner. I am so f*cking happy right now. I have literally been working on this machine none stop for 10 months and there is no way it would be working right now if it wasn't for you. Thank you so much man. Really.

Now before I get too excited I am going to try to do a test cut and make sure there aren't any other bugs lurking in the shadows.. I will post a .zip of the final config here in a moment for future reference to any poor soul who comes across this here forum.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

Man, if you are ever in New Mexico or Texas, my family wants to cook you dinner.

Thanks, I'll keep that in mind. Glad you got it working.

Please do.I will post a .zip of the final config here in a moment for future reference to any poor soul who comes across this here forum.

Although, if you are anything like me, there will never really be a 'final' version. I've been tinkering with mine for the last ten years.

Please Log in or Create an account to join the conversation.

- IronManDylan

- Offline

- Premium Member

-

- Posts: 151

- Thank you received: 22

So I was testing the machine by sending it gcode and was getting some weird 'follow' errors and 'limit' errors from the tool changes and from g43 being posted by the post processor. I fixed these errors by removing all the calls to tool change, and the g43 post, and the Htoonumber from the post processor. I have included my post processor file as well. Btw, if you are confused by how I am able to edit the post-processor so easily it is because I am using VS code. NYCNC on YouTube has a good video on how to use the software to show you where in the post processor a particular line of code is coming from. Works for the canned lines of code for LCNC. That plus "ctrl F" help me out.

Here is my plan to adjust tool height, and if someone has a better idea of how I should do this I am all ears as I have never 5 axis'd before. I have the pivot offset from the center of rotation to the surface of the spindle hardcoded into the INI file. Then I am planning to add the additional tool offset by using g43.1 to set the offset and g38.2 to find the probe with the tool (the biggest issue I can currently see with this is loosing that offset if I turn off the machine, in which case I should write it down or reprobe in...). I still have to figure out the best workflow for how to do that with the probes that I have (the probe module may be able to do all this in an automated way using M6, but I cannot see that part of the module because of axis gui), but this is my plan. I have a collet system in my machine, so I have to probe in the tool every time it is changed anyway, so having a tool library is not useful. Also. I cannot see if I have a tool "loaded" or not, because that information is at the bottom of AXIS gui and that is being cut off by my small screen. So that makes troubleshooting offsets more difficult. This way is more labor intensive than having it automated but...

The probing is buggy. It crashed once on me, just plowed right through my part. I can measure outside corners and edges just fine. However, I cannot measure for center finding, when I do so the probe centers about +.1" in y and x. Very odd. And annoying cause this is the feature that would be most useful to me. I wonder if "arm offset" is turned on and that is causing this issue or if it is something else. Again, I cannot see if it is turned on though cause AXIS gui is too long for my screen. Aciera, if you have any idea why this may be occurring, let me know.

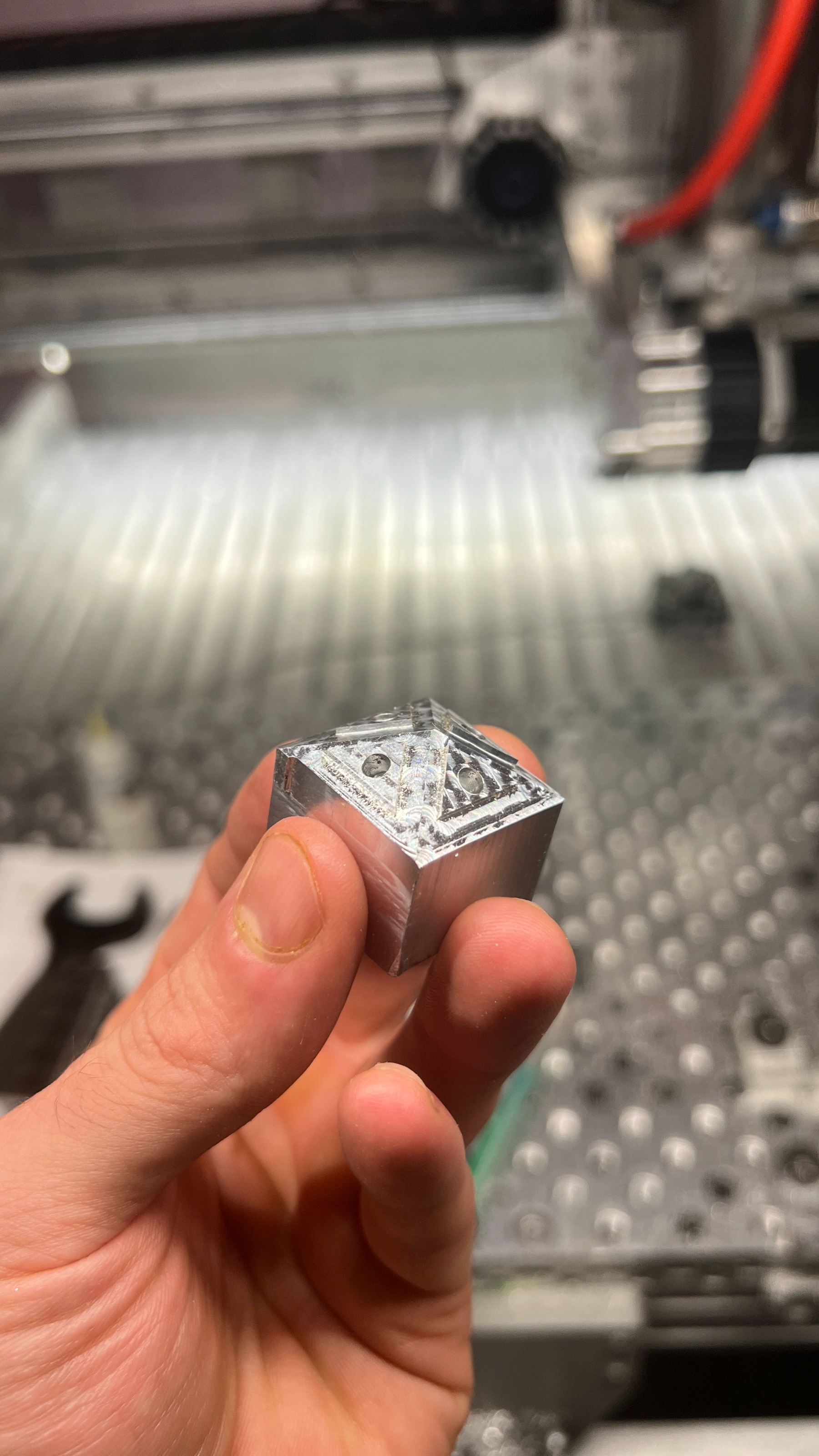

Beyond that I have tested everything else. Tool waits to spin up before it goes. It moves around in 5 axis seemingly okay. All that without my z axis having to become my y axis ;)I will do a test cut first thing tomorrow while I am fresh. Will post a photo.

PS: the compressed file is a .7z file even though it has the .tar extension (.tar file wouldn't fit...) and the .txt file is a .cps file (cant upload a .cps file here).

edit: I even wired up the table axis motor to make sure there weren't any surprises there and it is spinning and therefore appears to be working too!

Please Log in or Create an account to join the conversation.

- IronManDylan

- Offline

- Premium Member

-

- Posts: 151

- Thank you received: 22

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

More info here:

wiki.printnc.info/en/controllers/linuxcnc/tool-setter-no-probe

Regarding use of ProbeScreen I really have no idea since all I have ever used is a dial probe but this thread is about ProbeScreen from the very beginning so it goes back quite a few years. Maybe you can get some information there.

forum.linuxcnc.org/49-basic-configuratio...-with-probe?start=50

Please Log in or Create an account to join the conversation.

- IronManDylan

- Offline

- Premium Member

-

- Posts: 151

- Thank you received: 22

The alignment of my spindle center seems to be a little bit Y- to the joint of the A axis. So I need a way to fix this in the kinematic model. Do you know which of these need to be modified to do that:

HALCMD = sets :pivot-y 0

HALCMD = sets :pivot-z 2.3000

HALCMD = sets :offset-x 0

HALCMD = sets :offset-z 0

Obviously, I would think it would be "pivot-y", but 'pivot' seems like a strange term to call this. And you said that you modified this kinematics system off of another system, so I was wondering if they are labeled in an intuitive way. I am going to go try that now but was curious what you think.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

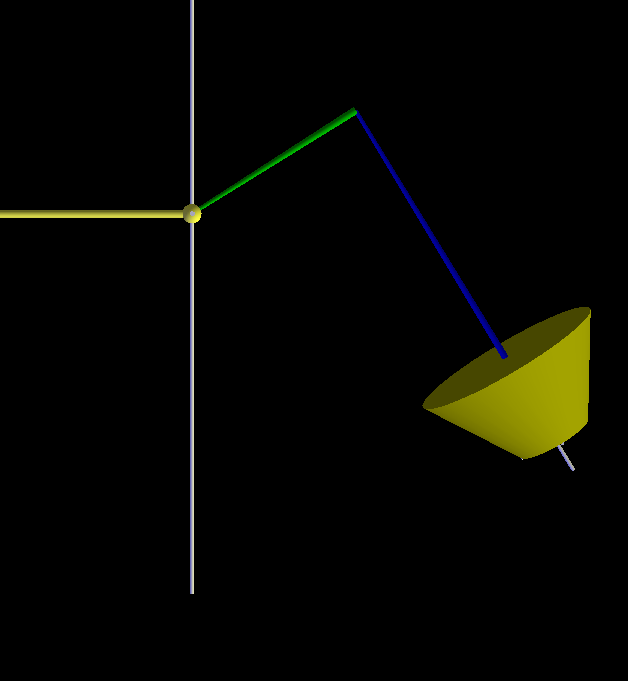

So this is a positive pivot_y:

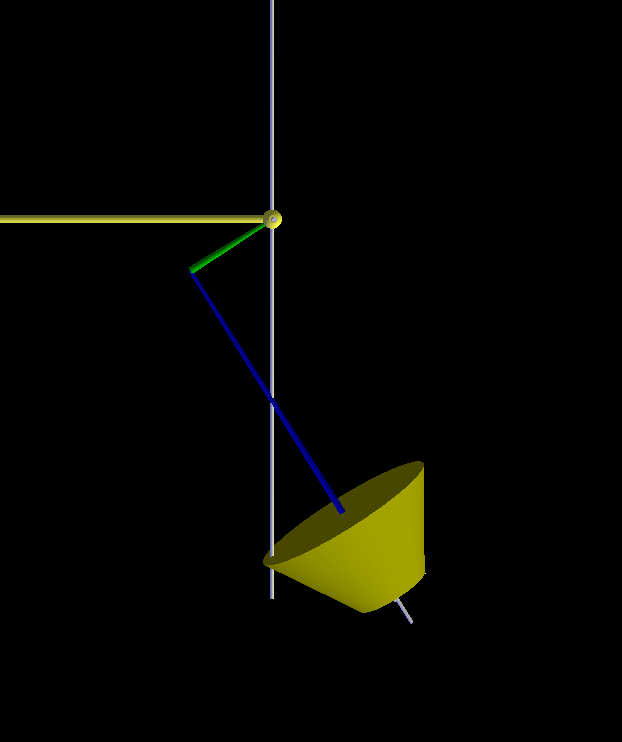

While this is a negative pivot_y:

Note: In the pictures

machine coordinate +Z is pointing UP

machine coordinate +Y is pointing LEFT

machine coordinate +X is pointing INTO the screen

Attachments:

Please Log in or Create an account to join the conversation.

- IronManDylan

- Offline

- Premium Member

-

- Posts: 151

- Thank you received: 22

It appears I have a smaller amount of error in b so I need to adjust that one too.

Glad you supplied me with such a robust kinematics system ?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4628

- Thank you received: 2049

[edit]

pivot-z / tool-length inaccuracies should cancel out when going from a20 to a-20

[edit2]

Or your lolly (if that is what you are using) is off center.

Please Log in or Create an account to join the conversation.