Search Results (Searched for: )

- behai

- behai

05 Apr 2025 04:41

- behai

- behai

05 Apr 2025 04:35

- tommylight

05 Apr 2025 04:06

Replied by tommylight on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- cmorley

- cmorley

05 Apr 2025 03:59

Replied by cmorley on topic Help,How to customize language of QtDragon's interface

Help,How to customize language of QtDragon's interface

Category: Qtvcp

- tommylight

05 Apr 2025 03:56

Replied by tommylight on topic Hypertherm Powermax Voltage Divider, Preference for THAD-10

Hypertherm Powermax Voltage Divider, Preference for THAD-10

Category: Plasmac

- tommylight

05 Apr 2025 03:38

Replied by tommylight on topic tangential knife along multiple layer height

tangential knife along multiple layer height

Category: AXIS

- tommylight

05 Apr 2025 03:33

Replied by tommylight on topic RPi 4B - LC2.8.4 vs LC2.9.2 - Queue MDI Commands, Run From Here

RPi 4B - LC2.8.4 vs LC2.9.2 - Queue MDI Commands, Run From Here

Category: Basic Configuration

- heaven

- heaven

05 Apr 2025 03:05

Replied by heaven on topic Moving robot joints by only 1 Gcode command?

Moving robot joints by only 1 Gcode command?

Category: Advanced Configuration

- terrymackintosh

- terrymackintosh

05 Apr 2025 03:01

Replied by terrymackintosh on topic RPi 4B - LC2.8.4 vs LC2.9.2 - Queue MDI Commands, Run From Here

RPi 4B - LC2.8.4 vs LC2.9.2 - Queue MDI Commands, Run From Here

Category: Basic Configuration

- tommylight

05 Apr 2025 02:54

- vre

- vre

05 Apr 2025 02:50

Replied by vre on topic Help,How to customize language of QtDragon's interface

Help,How to customize language of QtDragon's interface

Category: Qtvcp

- ffffrf

- ffffrf

05 Apr 2025 01:24 - 05 Apr 2025 01:28

- ContinenteCNC

05 Apr 2025 01:21

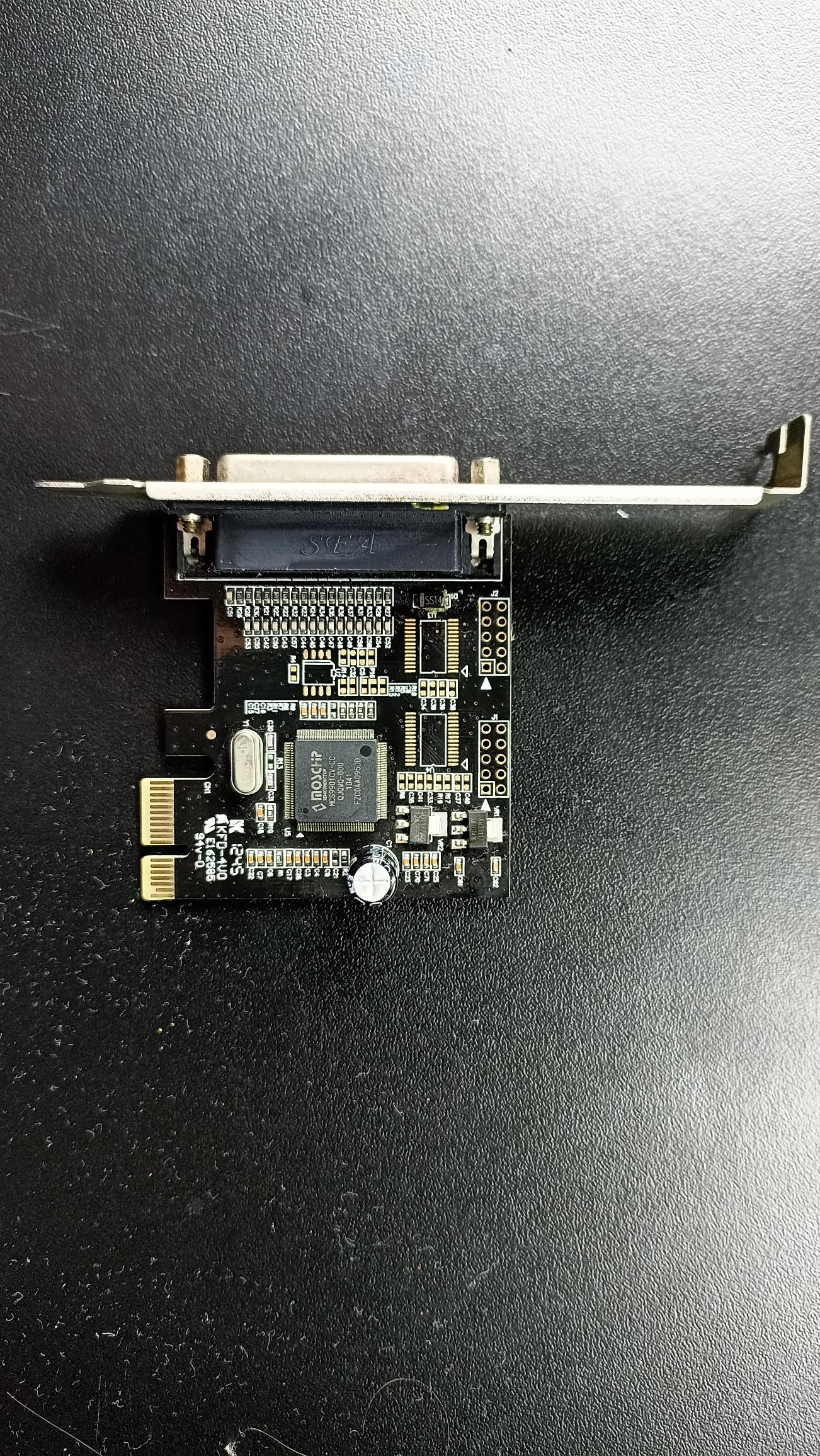

Replied by ContinenteCNC on topic PCIe - No parport registered at "0x " . This is not Always an error.Continuing.

PCIe - No parport registered at "0x " . This is not Always an error.Continuing.

Category: Advanced Configuration

- ContinenteCNC

05 Apr 2025 01:13 - 05 Apr 2025 01:14

Replied by ContinenteCNC on topic PCI and PCI-E add on cards with parallel port that work out of the box

PCI and PCI-E add on cards with parallel port that work out of the box

Category: Computers and Hardware

- COFHAL

- COFHAL

05 Apr 2025 00:31

Time to create page: 0.778 seconds