Search Results (Searched for: )

- Tinker

- Tinker

22 Feb 2025 20:59

Replied by Tinker on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- RDA

- RDA

22 Feb 2025 20:40

Replied by RDA on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- cakeslob

- cakeslob

22 Feb 2025 20:39

Replied by cakeslob on topic What commercial machines use Linux CnC

What commercial machines use Linux CnC

Category: General LinuxCNC Questions

- tommylight

22 Feb 2025 20:38

Replied by tommylight on topic Operating computers in the cold

Operating computers in the cold

Category: Computers and Hardware

- RDA

- RDA

22 Feb 2025 20:34

Replied by RDA on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- tommylight

22 Feb 2025 20:32

Replied by tommylight on topic What commercial machines use Linux CnC

What commercial machines use Linux CnC

Category: General LinuxCNC Questions

- tommylight

22 Feb 2025 20:24

Replied by tommylight on topic Linuxcnc hotspot on raspberry pi

Linuxcnc hotspot on raspberry pi

Category: General LinuxCNC Questions

- NT4Boy

- NT4Boy

22 Feb 2025 20:23

Replied by NT4Boy on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- Hakan

- Hakan

22 Feb 2025 20:12

Replied by Hakan on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- smc.collins

- smc.collins

22 Feb 2025 19:54

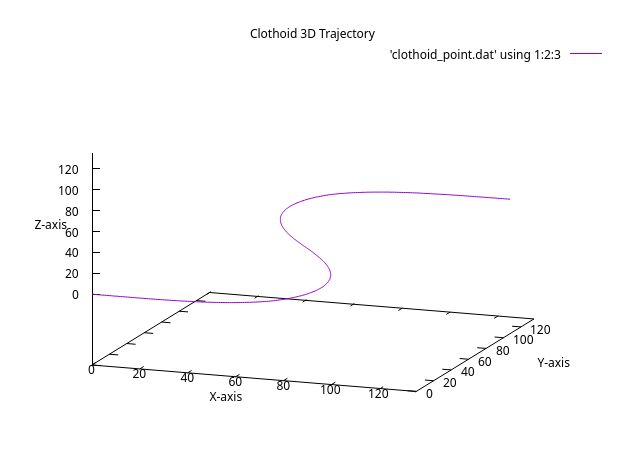

Replied by smc.collins on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- jyeomans

- jyeomans

22 Feb 2025 19:53

- Dedeer

- Dedeer

22 Feb 2025 19:32

Replied by Dedeer on topic Operating computers in the cold

Operating computers in the cold

Category: Computers and Hardware

- rodw

22 Feb 2025 19:30

Replied by rodw on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- Boogie

- Boogie

22 Feb 2025 19:29

- rodw

22 Feb 2025 19:28

Replied by rodw on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

Time to create page: 0.394 seconds