Search Results (Searched for: )

- tommy

- tommy

10 Feb 2025 09:05

Replied by tommy on topic 7i95T + 7i78 spindle configuration

7i95T + 7i78 spindle configuration

Category: Basic Configuration

- meister

- meister

10 Feb 2025 08:53

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- partec

- partec

10 Feb 2025 08:41 - 10 Feb 2025 08:54

Replied by partec on topic Welding CNC-Touch sensing

Welding CNC-Touch sensing

Category: General LinuxCNC Questions

- automata

- automata

10 Feb 2025 08:35

Replied by automata on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Martin.L

- Martin.L

10 Feb 2025 06:50

Replied by Martin.L on topic EtherCAT + lcec + cia402 + PID on A6-1000EC in velocity control mode

EtherCAT + lcec + cia402 + PID on A6-1000EC in velocity control mode

Category: EtherCAT

- beauxnez

- beauxnez

10 Feb 2025 05:18 - 10 Feb 2025 05:19

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- cakeslob

- cakeslob

10 Feb 2025 05:06

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- akg1904

- akg1904

10 Feb 2025 04:34

Replied by akg1904 on topic Pitch Error Compensation explanation

Pitch Error Compensation explanation

Category: General LinuxCNC Questions

- beauxnez

- beauxnez

10 Feb 2025 04:13

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Lcvette

10 Feb 2025 02:18

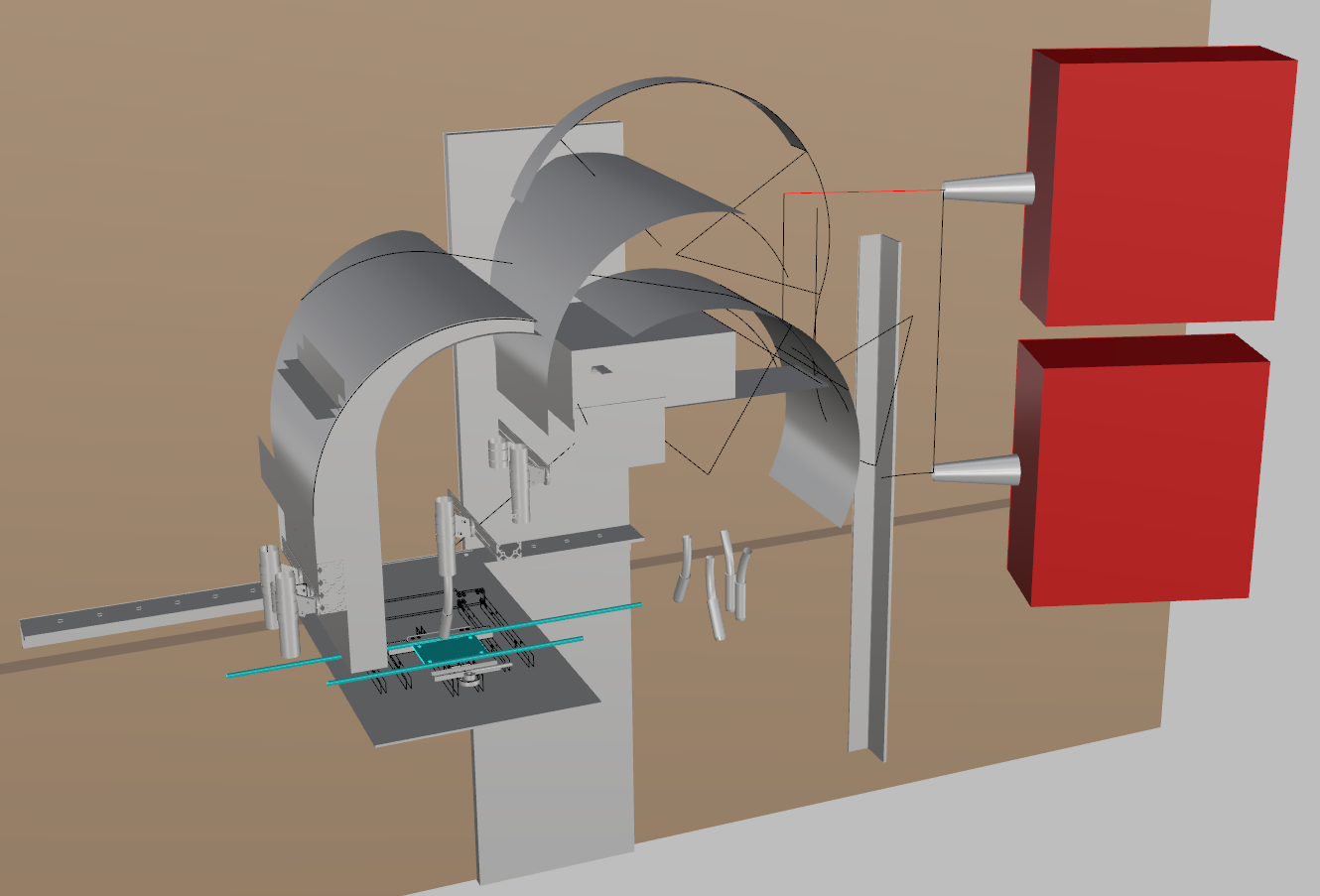

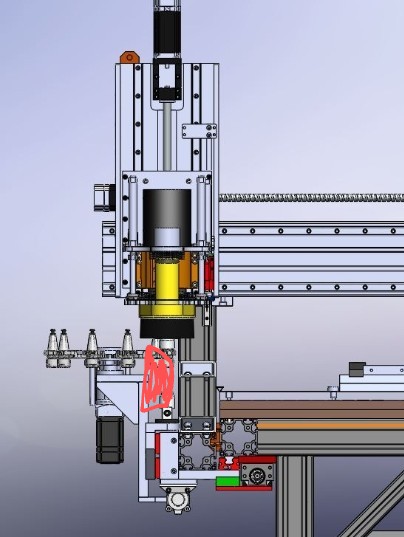

Replied by Lcvette on topic ProbeBasic and sidemount, retractable 3D Probe

ProbeBasic and sidemount, retractable 3D Probe

Category: QtPyVCP

- grandixximo

10 Feb 2025 02:16 - 10 Feb 2025 07:46

Vscode gcode highlight and formatter, with subroutine support was created by grandixximo

Vscode gcode highlight and formatter, with subroutine support

Category: O Codes (subroutines) and NGCGUI

- Grotius

10 Feb 2025 01:43

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- PCW

09 Feb 2025 23:37

- unknown

- unknown

09 Feb 2025 23:30

Replied by unknown on topic From Grbl to linuxcnc

From Grbl to linuxcnc

Category: General LinuxCNC Questions

- unknown

- unknown

09 Feb 2025 23:24

Replied by unknown on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

Time to create page: 1.163 seconds