Search Results (Searched for: )

- RV3Dtech

- RV3Dtech

14 Jan 2025 20:22

- dg9mdr

- dg9mdr

14 Jan 2025 20:05

Replied by dg9mdr on topic Maus funktioniert nicht bei Spindel Start

Maus funktioniert nicht bei Spindel Start

Category: Deutsch

- DieLimo

- DieLimo

14 Jan 2025 20:02 - 14 Jan 2025 20:12

Coordinate system in GUI does not match machine was created by DieLimo

Coordinate system in GUI does not match machine

Category: Basic Configuration

- Aciera

14 Jan 2025 19:40

Replied by Aciera on topic How to call a python script in gcode

How to call a python script in gcode

Category: General LinuxCNC Questions

- programador

14 Jan 2025 19:29 - 14 Jan 2025 19:34

Replied by programador on topic How to call a python script in gcode

How to call a python script in gcode

Category: General LinuxCNC Questions

- PCW

14 Jan 2025 19:11

- HansU

14 Jan 2025 19:07

Replied by HansU on topic Probe screen for WXGA monitor with 1366x768 dpi in linuxcnc 2.9

Probe screen for WXGA monitor with 1366x768 dpi in linuxcnc 2.9

Category: Gmoccapy

- programador

14 Jan 2025 19:01

Replied by programador on topic How to use the velocity encoder signal as position feedback for the 7i77 board?

How to use the velocity encoder signal as position feedback for the 7i77 board?

Category: HAL

- PCW

14 Jan 2025 18:30

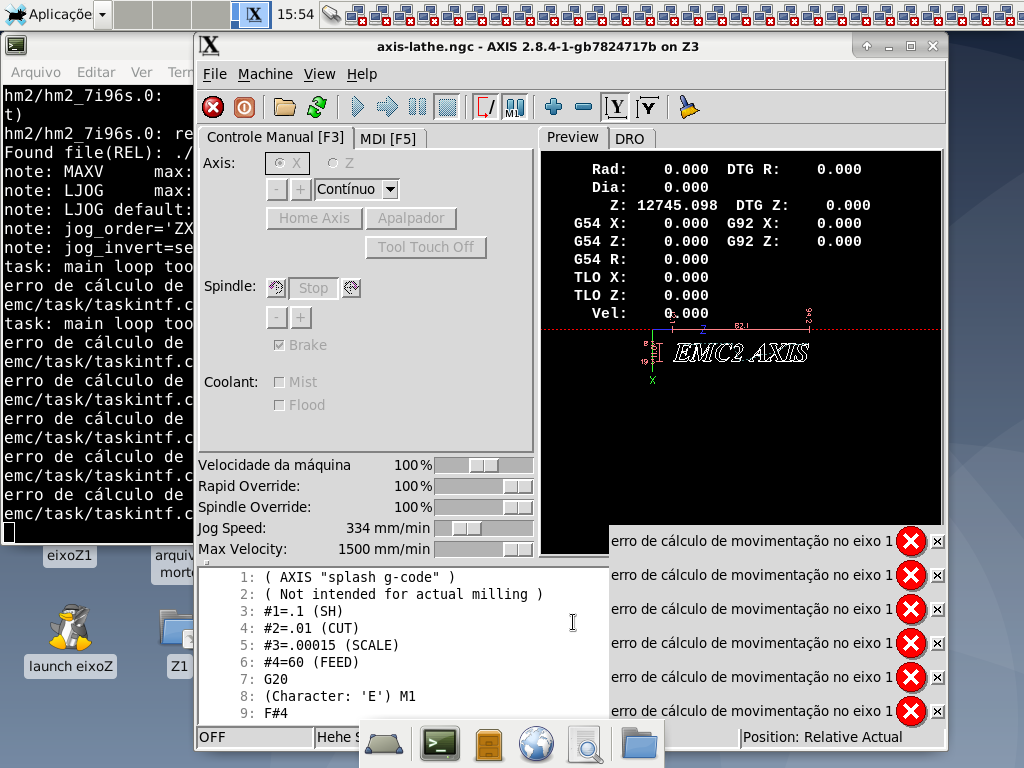

Replied by PCW on topic Error problem hm2 7i96s 7i77 analogout scalemax not found ?

Error problem hm2 7i96s 7i77 analogout scalemax not found ?

Category: HAL

- programador

14 Jan 2025 18:13

Replied by programador on topic Error problem hm2 7i96s 7i77 analogout scalemax not found ?

Error problem hm2 7i96s 7i77 analogout scalemax not found ?

Category: HAL

- PCW

14 Jan 2025 18:09

- programador

14 Jan 2025 17:58

- TomAlborough

14 Jan 2025 17:56

Replied by TomAlborough on topic RPi 5 with 6.12 PREEMPT_RT = Using POSIX non-realtime

RPi 5 with 6.12 PREEMPT_RT = Using POSIX non-realtime

Category: Installing LinuxCNC

- Clive S

- Clive S

14 Jan 2025 17:10

Replied by Clive S on topic Homing an axis moves away from home switch!

Homing an axis moves away from home switch!

Category: StepConf Wizard

- langdons

14 Jan 2025 17:09

Replied by langdons on topic Homing an axis moves away from home switch!

Homing an axis moves away from home switch!

Category: StepConf Wizard

Time to create page: 0.461 seconds