Search Results (Searched for: )

- Lcvette

18 Oct 2024 13:35

Replied by Lcvette on topic Tool length sensor direction change

Tool length sensor direction change

Category: QtPyVCP

- tsaG

- tsaG

18 Oct 2024 13:23 - 18 Oct 2024 13:29

Replied by tsaG on topic Tool length sensor direction change

Tool length sensor direction change

Category: QtPyVCP

- flexbex

- flexbex

18 Oct 2024 13:15

- Grotius

18 Oct 2024 13:13

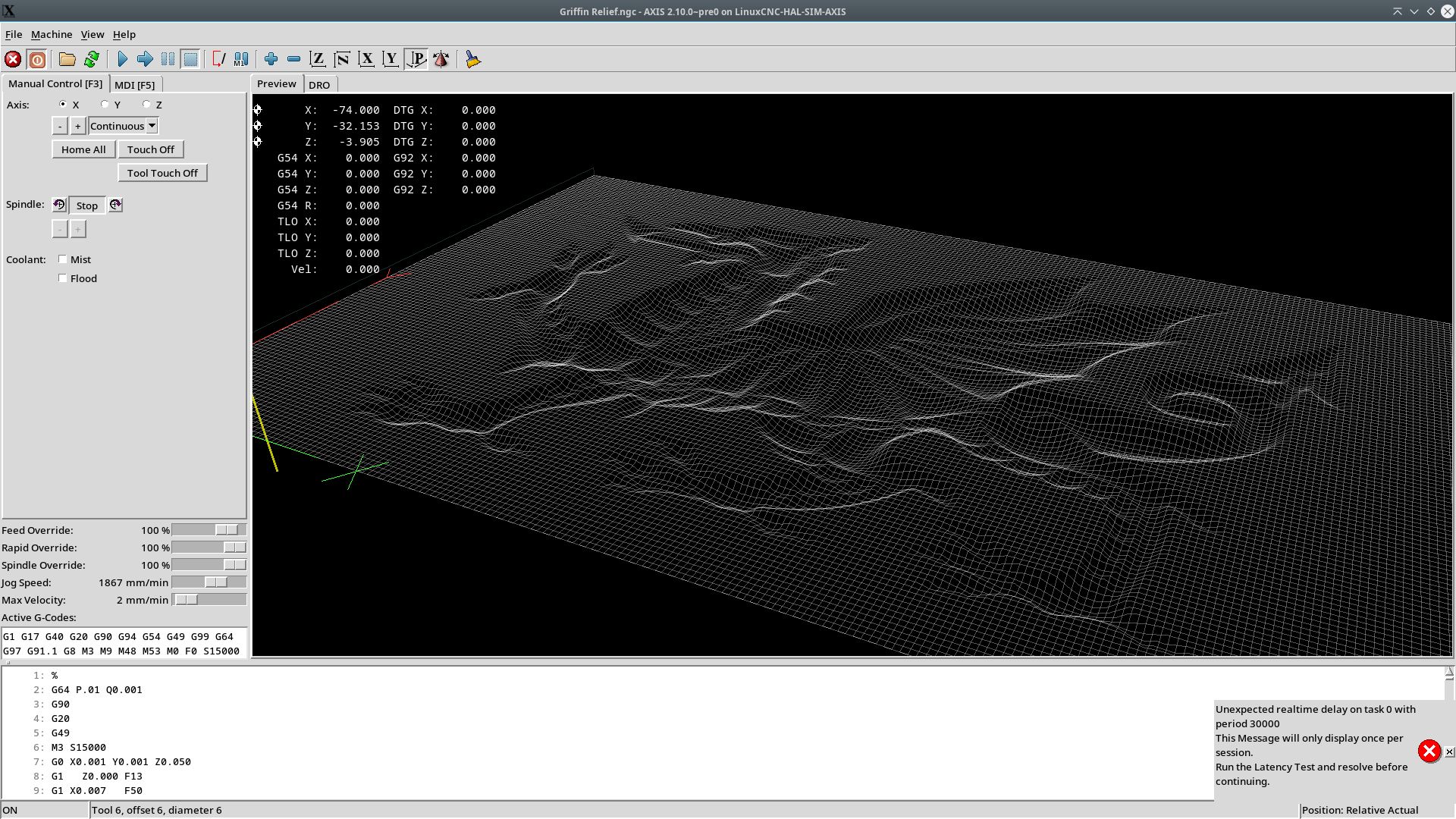

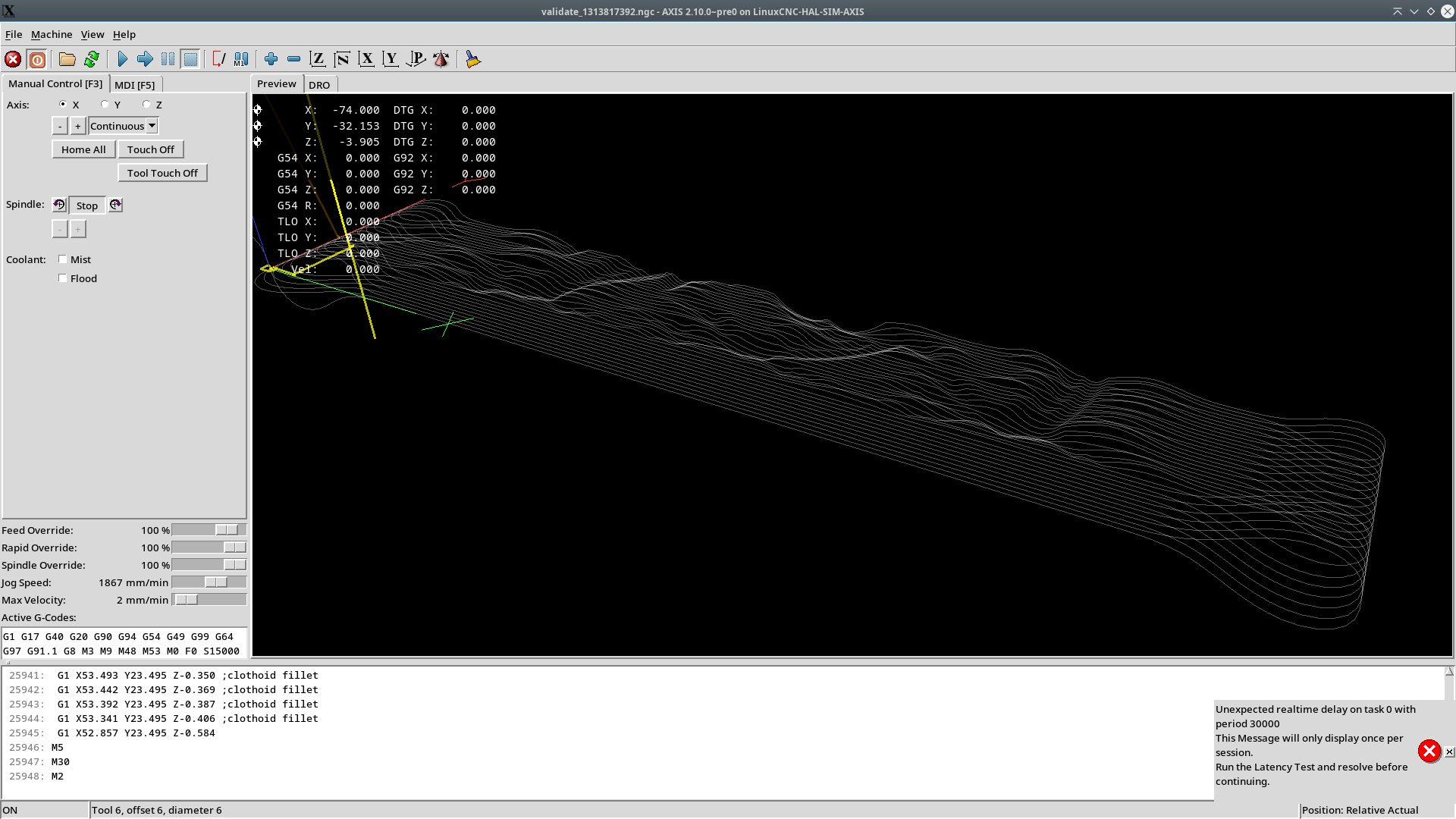

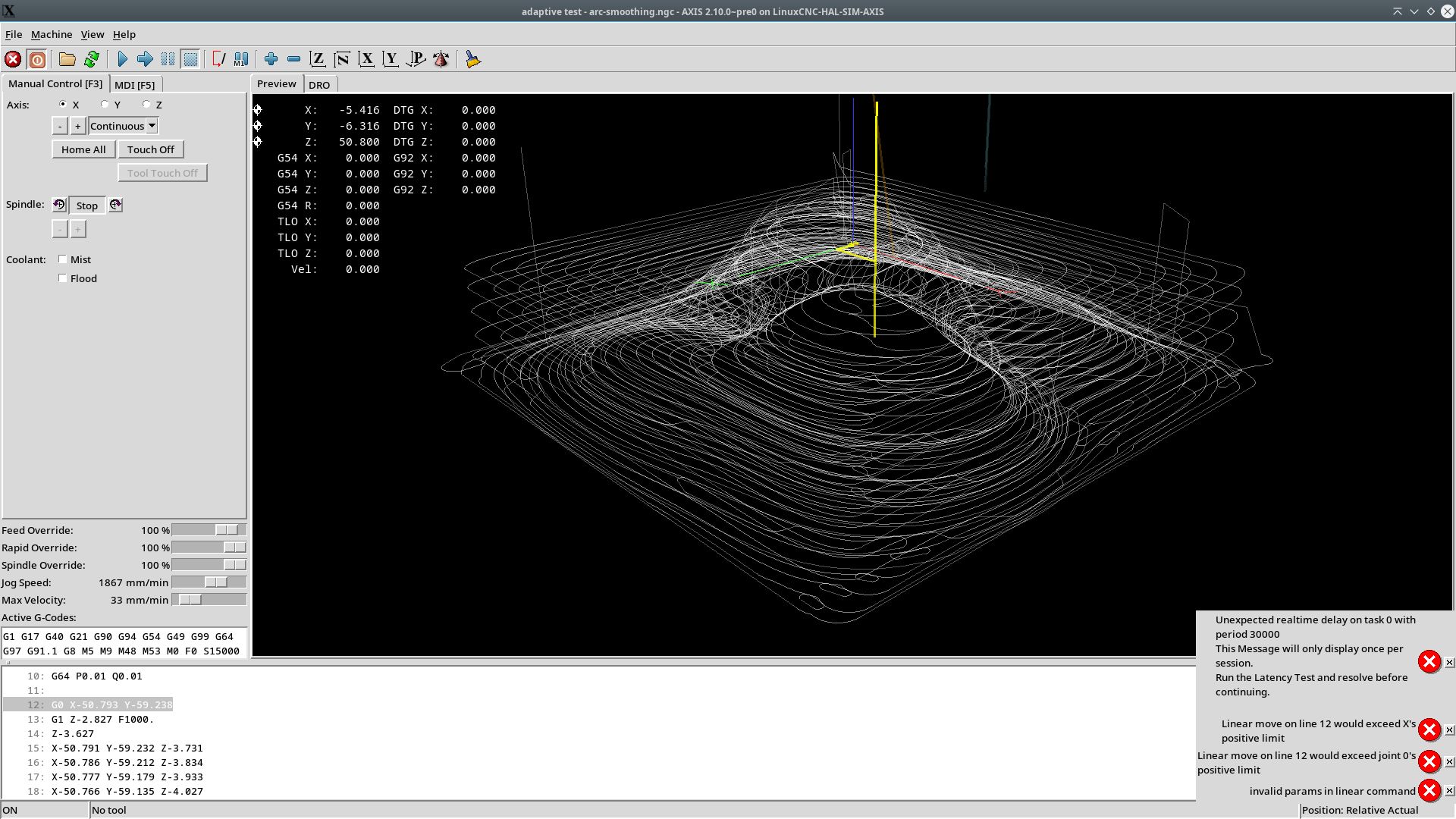

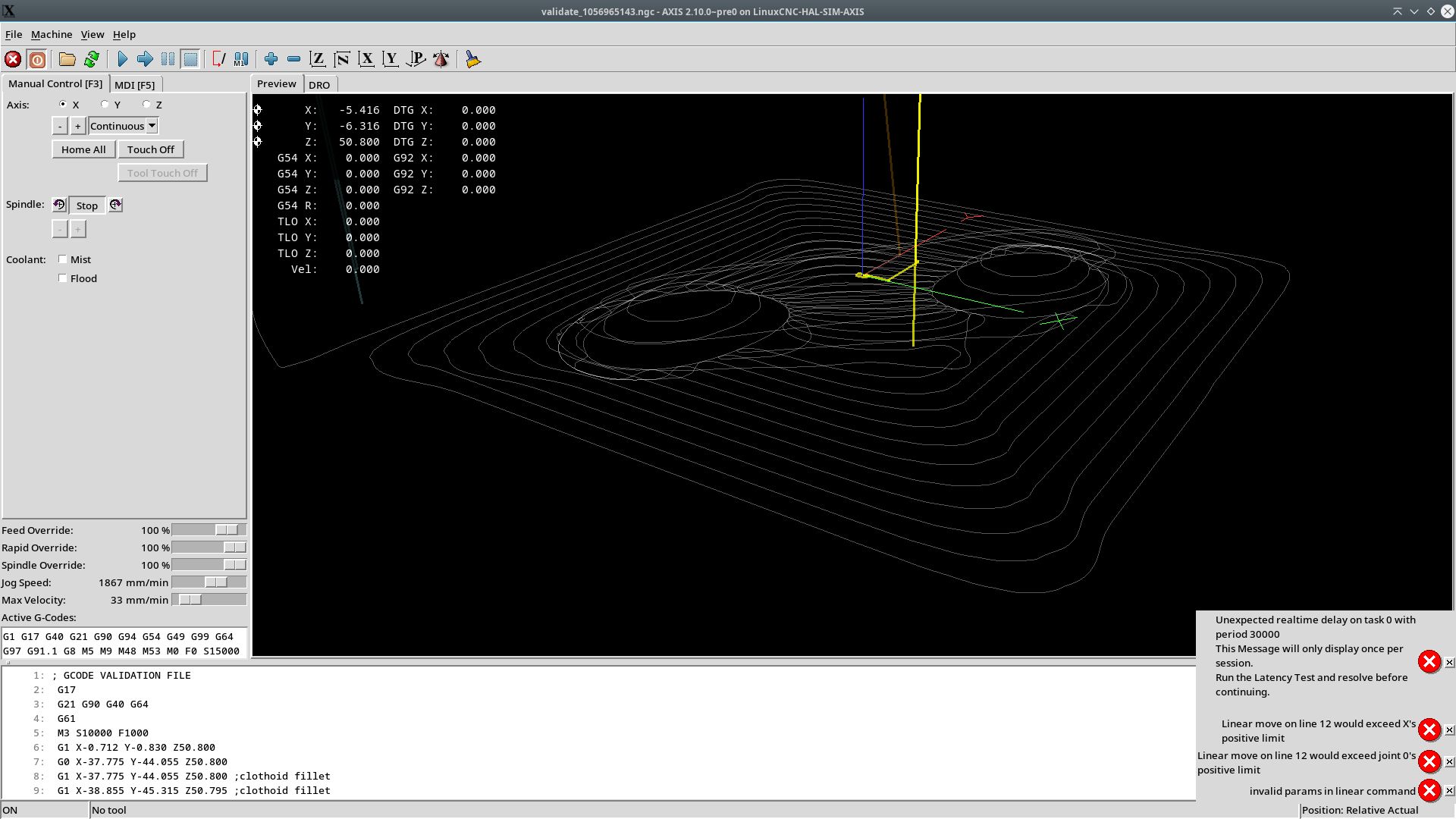

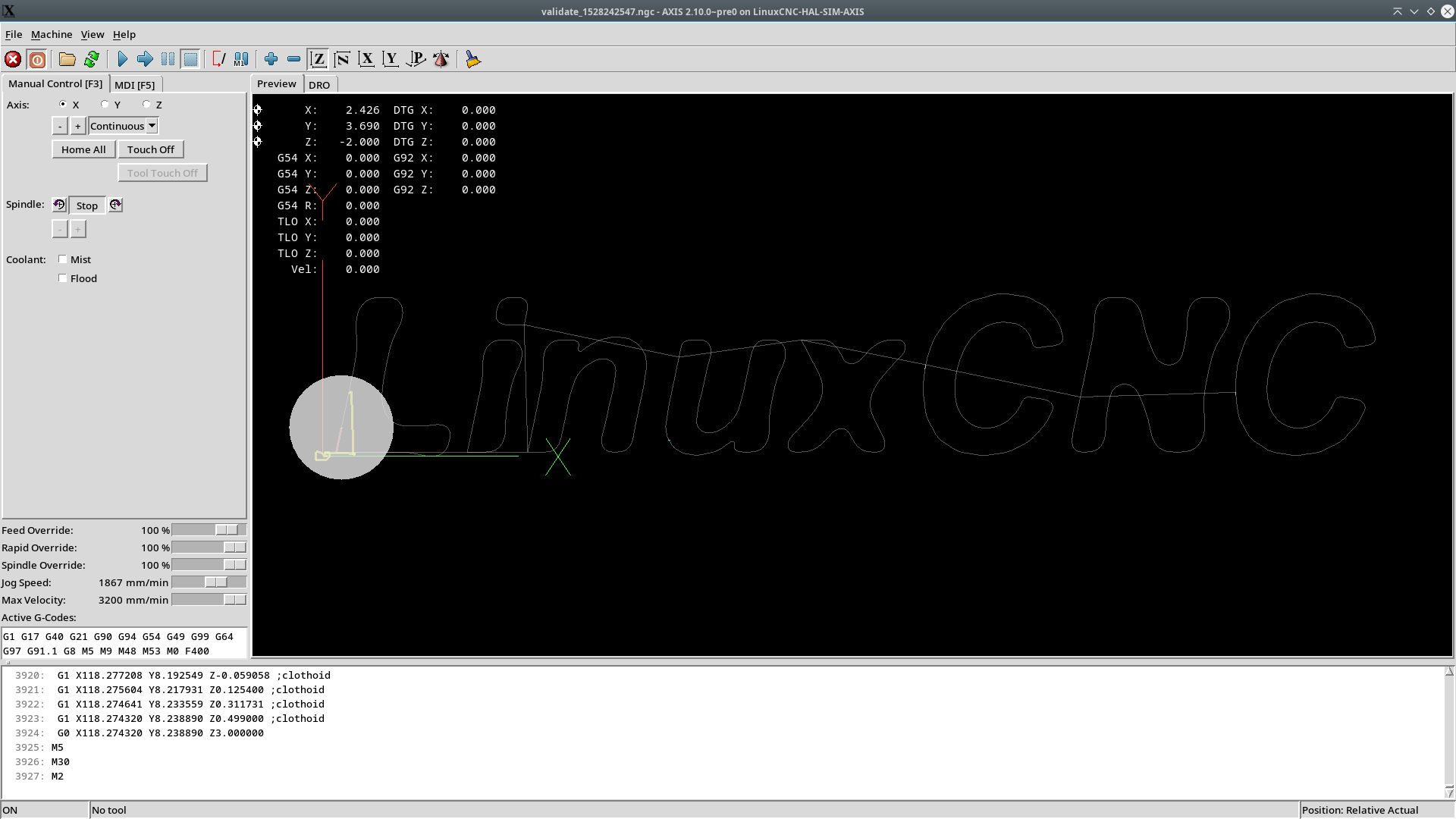

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- rajsekhar

- rajsekhar

18 Oct 2024 13:07

- royka

- royka

18 Oct 2024 13:04

Replied by royka on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- Aciera

18 Oct 2024 12:15

Replied by Aciera on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- JT

18 Oct 2024 12:00

- Grotius

18 Oct 2024 11:56

Replied by Grotius on topic c++ compiling error

c++ compiling error

Category: Advanced Configuration

- Grotius

18 Oct 2024 11:39

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- Lcvette

18 Oct 2024 11:37

Replied by Lcvette on topic Another Idiot attempts to use Probe Basic and begs for help

Another Idiot attempts to use Probe Basic and begs for help

Category: QtPyVCP

- rajsekhar

- rajsekhar

18 Oct 2024 11:34

Replied by rajsekhar on topic Latency and Graphics Card

Latency and Graphics Card

Category: General LinuxCNC Questions

- tsaG

- tsaG

18 Oct 2024 11:33

Replied by tsaG on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

[ Vfdmod ] An easy VFD control over MODBUS RTU

Category: HAL

- FedX

- FedX

18 Oct 2024 11:30 - 18 Oct 2024 13:23

- Lcvette

18 Oct 2024 11:29

Replied by Lcvette on topic Another Idiot attempts to use Probe Basic and begs for help

Another Idiot attempts to use Probe Basic and begs for help

Category: QtPyVCP

Time to create page: 1.021 seconds