Search Results (Searched for: )

- PCW

19 Oct 2024 15:25

Replied by PCW on topic 7i92+7i77 basic comms again

7i92+7i77 basic comms again

Category: General LinuxCNC Questions

- PCW

19 Oct 2024 15:21

- tommylight

19 Oct 2024 15:09

Replied by tommylight on topic 7i92+7i77 basic comms again

7i92+7i77 basic comms again

Category: General LinuxCNC Questions

- gardenweazel

19 Oct 2024 15:06

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- 3CHman

- 3CHman

19 Oct 2024 15:02

7i92+7i77 basic comms again was created by 3CHman

7i92+7i77 basic comms again

Category: General LinuxCNC Questions

- Deckerjwd

19 Oct 2024 14:49

Replied by Deckerjwd on topic Holes have a taper

Holes have a taper

Category: General LinuxCNC Questions

- Grotius

19 Oct 2024 14:48

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- Deckerjwd

19 Oct 2024 14:21

Replied by Deckerjwd on topic 7I33TA Just plug it in?

7I33TA Just plug it in?

Category: Driver Boards

- bkt

19 Oct 2024 13:54 - 19 Oct 2024 14:02

- chuben

- chuben

19 Oct 2024 13:40

- Macwolf

- Macwolf

19 Oct 2024 13:33 - 19 Oct 2024 14:28

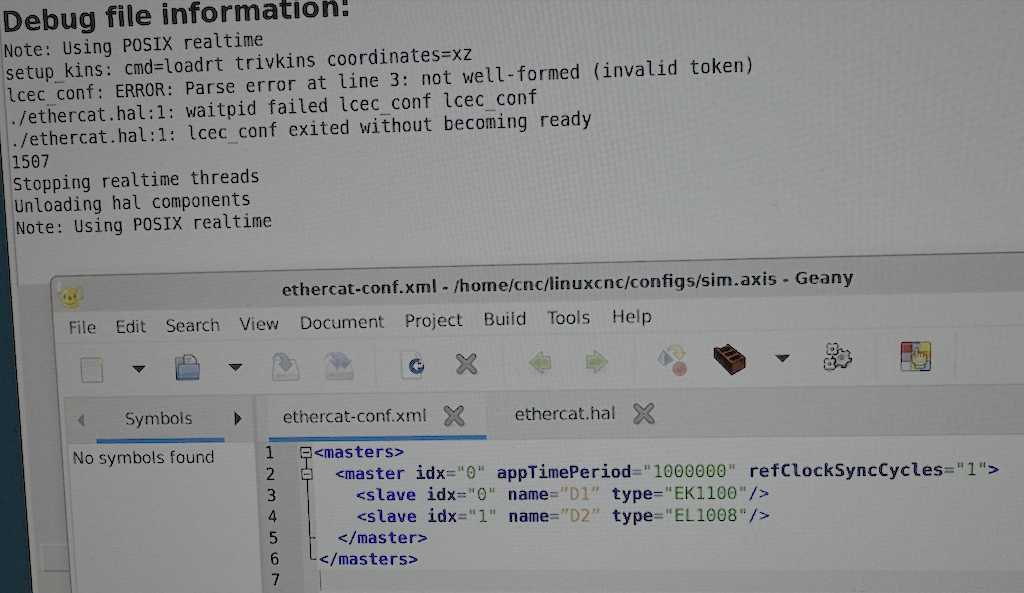

Replied by Macwolf on topic Beckhoff components crasht Linuxcnc

Beckhoff components crasht Linuxcnc

Category: EtherCAT

- kworm

- kworm

19 Oct 2024 13:25

Replied by kworm on topic Beckhoff components crasht Linuxcnc

Beckhoff components crasht Linuxcnc

Category: EtherCAT

- royka

- royka

19 Oct 2024 13:21 - 19 Oct 2024 17:17

Replied by royka on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- sajurcaju

- sajurcaju

19 Oct 2024 13:03

- Aciera

19 Oct 2024 13:02

Replied by Aciera on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

Time to create page: 6.848 seconds