Search Results (Searched for: )

- cutnweld

- cutnweld

26 Jul 2024 15:19

- Cant do this anymore bye all

26 Jul 2024 15:16

Replied by Cant do this anymore bye all on topic LinuxCNC machine setup with Rasperry Pi4 and Mesa 7i76 for communication

LinuxCNC machine setup with Rasperry Pi4 and Mesa 7i76 for communication

Category: General LinuxCNC Questions

- Aciera

26 Jul 2024 15:14

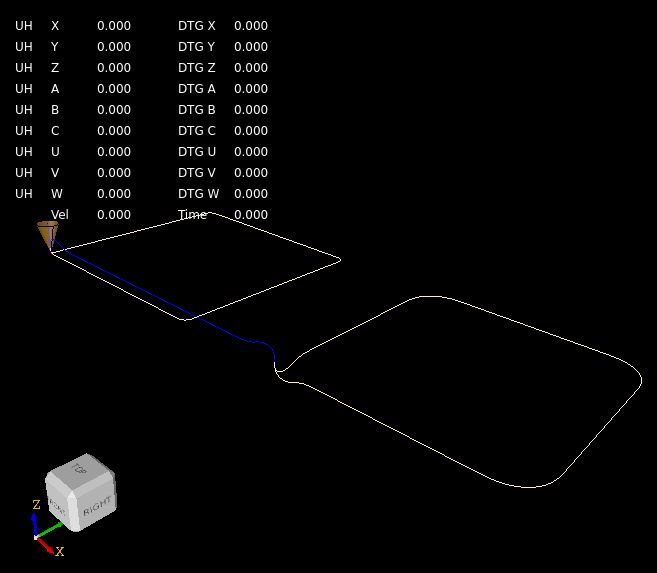

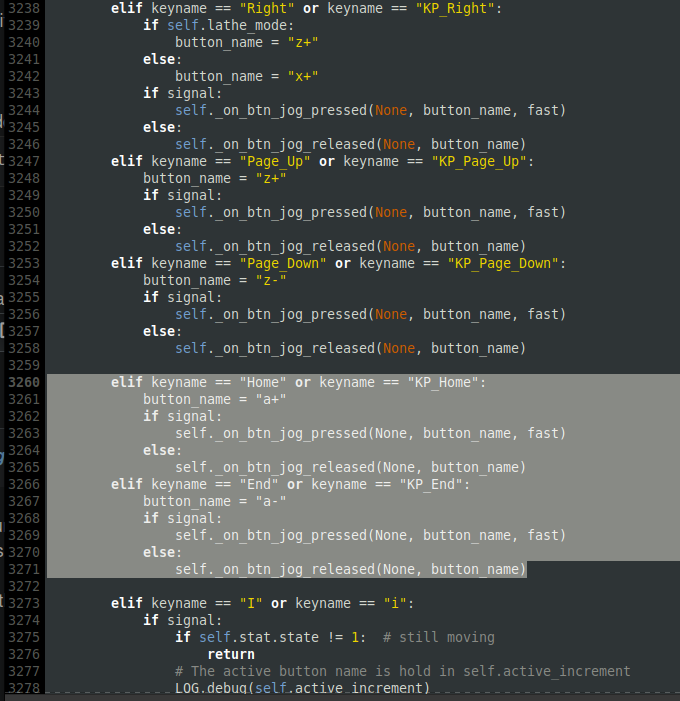

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- elovalvo

- elovalvo

26 Jul 2024 15:13

Replied by elovalvo on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- jmelson

- jmelson

26 Jul 2024 15:06

Replied by jmelson on topic Yaskawa incremental encoder and Mesa 7i48

Yaskawa incremental encoder and Mesa 7i48

Category: Driver Boards

- sin-do-re

- sin-do-re

26 Jul 2024 15:01

Replied by sin-do-re on topic Inserting an Output-ON M-Code in QtPlasmac g-code

Inserting an Output-ON M-Code in QtPlasmac g-code

Category: General LinuxCNC Questions

- Lcvette

26 Jul 2024 14:46

Replied by Lcvette on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Lcvette

26 Jul 2024 14:41

Replied by Lcvette on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Aciera

26 Jul 2024 14:08

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Aciera

26 Jul 2024 14:01 - 26 Jul 2024 14:02

Replied by Aciera on topic Taig Lathe conversion to LinuxCNC: M3 is not turning on spindle

Taig Lathe conversion to LinuxCNC: M3 is not turning on spindle

Category: StepConf Wizard

- Grotius

26 Jul 2024 14:00

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Aciera

26 Jul 2024 13:55

Replied by Aciera on topic Taig Lathe conversion to LinuxCNC: M3 is not turning on spindle

Taig Lathe conversion to LinuxCNC: M3 is not turning on spindle

Category: StepConf Wizard

- mariusl

26 Jul 2024 13:37

- Cerezas

- Cerezas

26 Jul 2024 13:33

- Aciera

26 Jul 2024 13:22

Time to create page: 0.460 seconds