Search Results (Searched for: )

- Grotius

22 Oct 2024 10:08

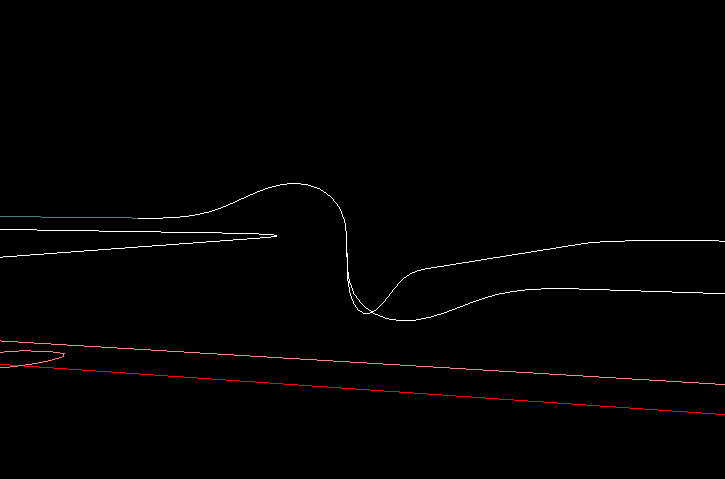

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- yuyu

- yuyu

22 Oct 2024 09:55 - 22 Oct 2024 09:56

- ThyerHazard

22 Oct 2024 09:20

- martin2day

- martin2day

22 Oct 2024 08:00

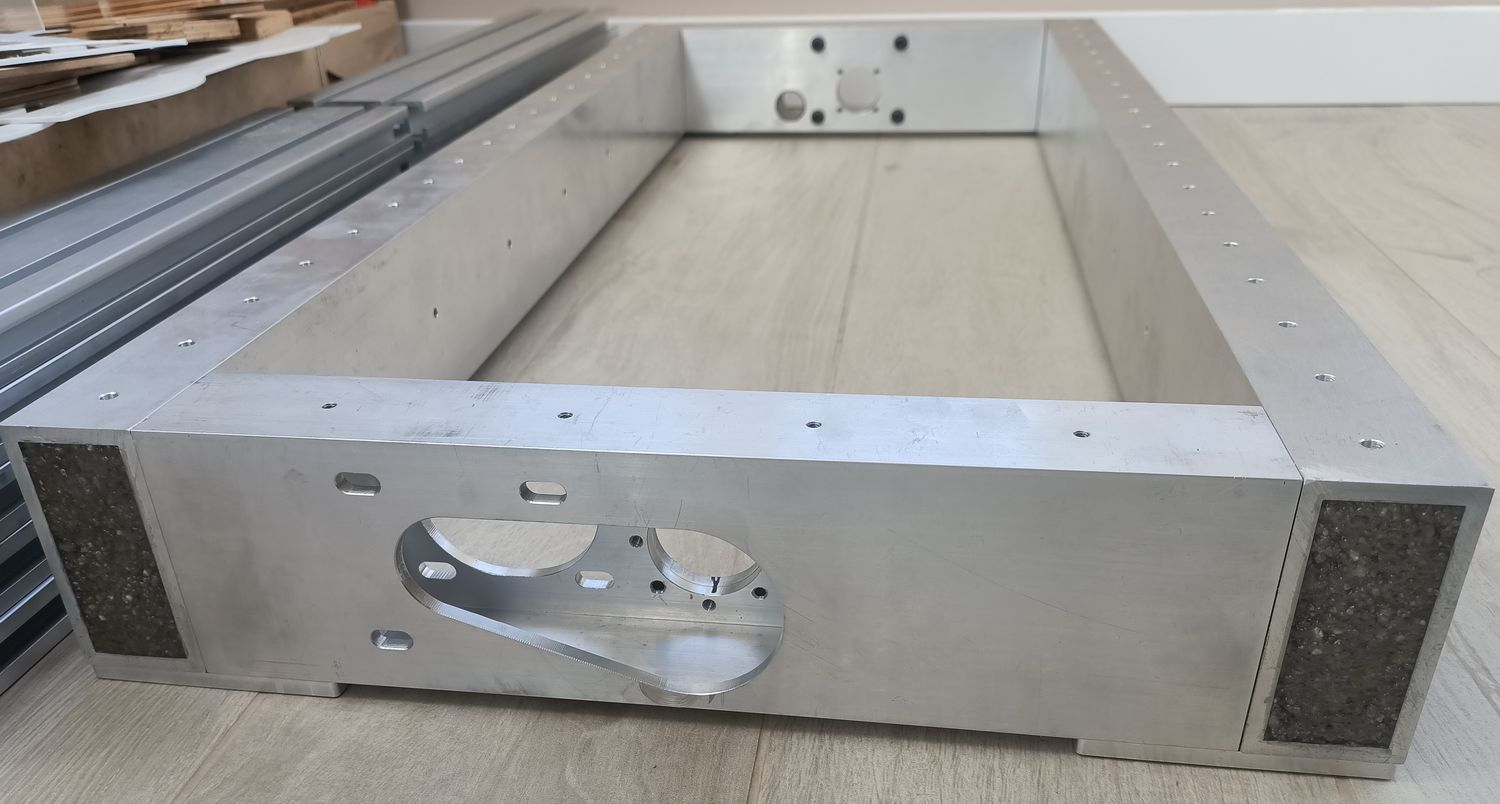

Replied by martin2day on topic Knuth Mark Super CNC Retrofit - need some help with my first LinuxCNC

Knuth Mark Super CNC Retrofit - need some help with my first LinuxCNC

Category: Milling Machines

- Aciera

22 Oct 2024 07:50 - 22 Oct 2024 08:14

Replied by Aciera on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- bkt

22 Oct 2024 06:43

- ThyerHazard

22 Oct 2024 06:43

- bkt

22 Oct 2024 06:37

- bkt

22 Oct 2024 06:17 - 22 Oct 2024 06:19

- Mr. Mass

22 Oct 2024 06:15 - 22 Oct 2024 06:18

- Aciera

22 Oct 2024 06:03 - 22 Oct 2024 07:40

Replied by Aciera on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- cmorley

- cmorley

22 Oct 2024 04:02

Replied by cmorley on topic Machine moves when you stop program in the middle

Machine moves when you stop program in the middle

Category: General LinuxCNC Questions

- tommylight

22 Oct 2024 02:51

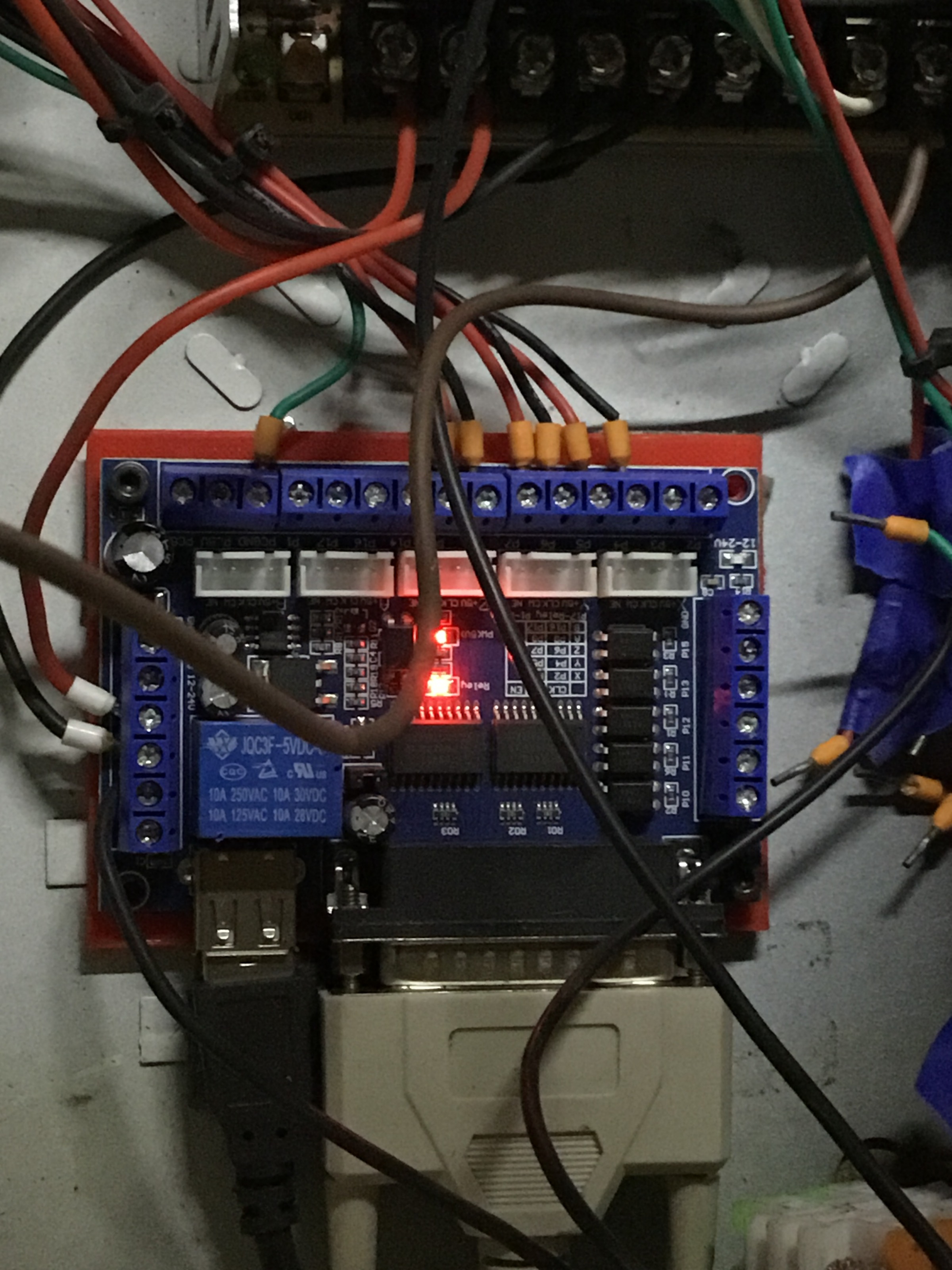

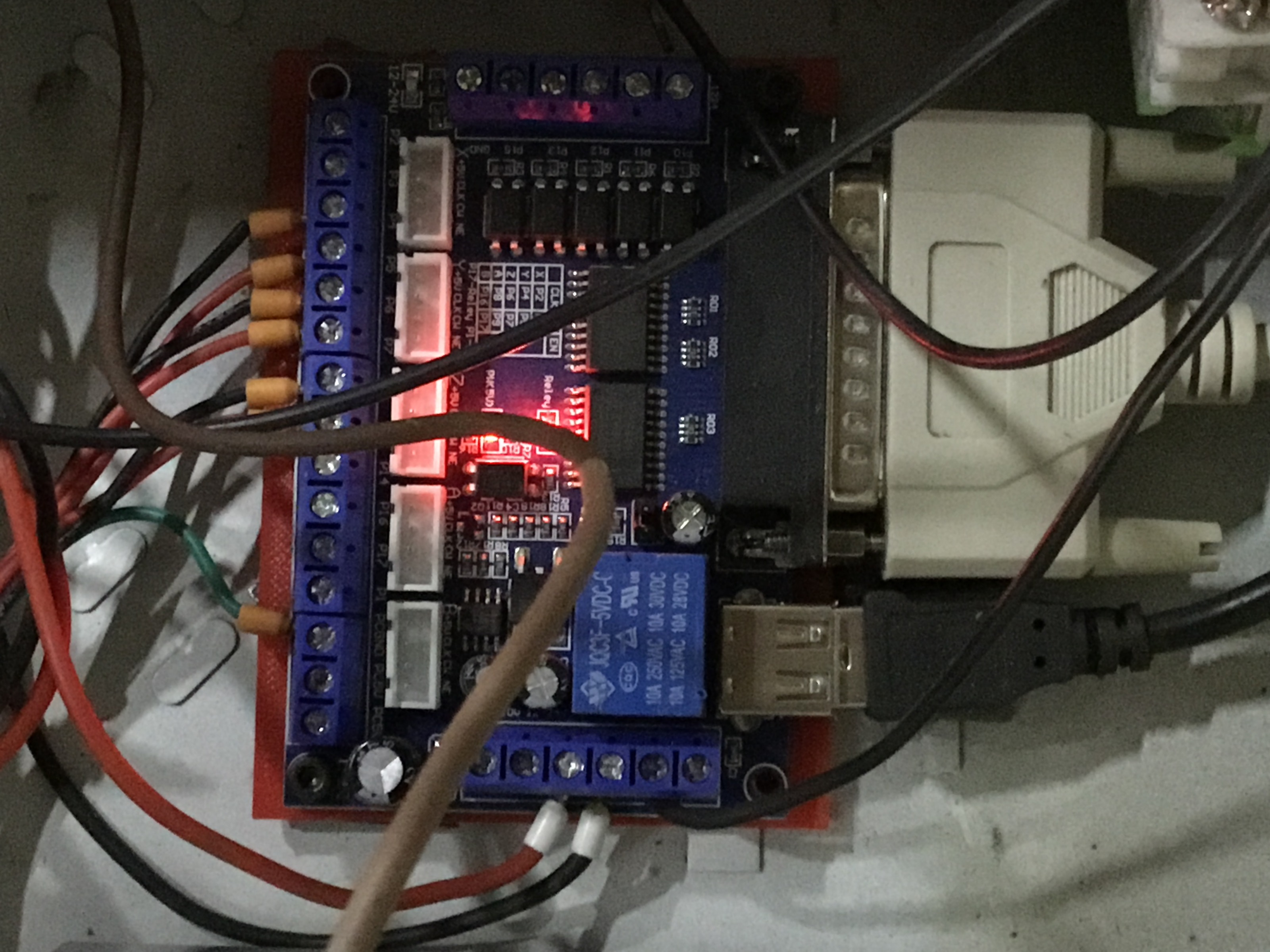

Replied by tommylight on topic controller and motors not fully communicating

controller and motors not fully communicating

Category: General LinuxCNC Questions

- tommylight

22 Oct 2024 02:46

Replied by tommylight on topic manueller Werkzeugwechsel/-auswahl

manueller Werkzeugwechsel/-auswahl

Category: Deutsch

- foam man

- foam man

22 Oct 2024 02:44

Replied by foam man on topic controller and motors not fully communicating

controller and motors not fully communicating

Category: General LinuxCNC Questions

Time to create page: 0.589 seconds