Search Results (Searched for: )

- Giovanni

- Giovanni

03 Oct 2024 11:09

Replied by Giovanni on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

- Grotius

03 Oct 2024 10:47

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- PeterSi

- PeterSi

03 Oct 2024 10:42

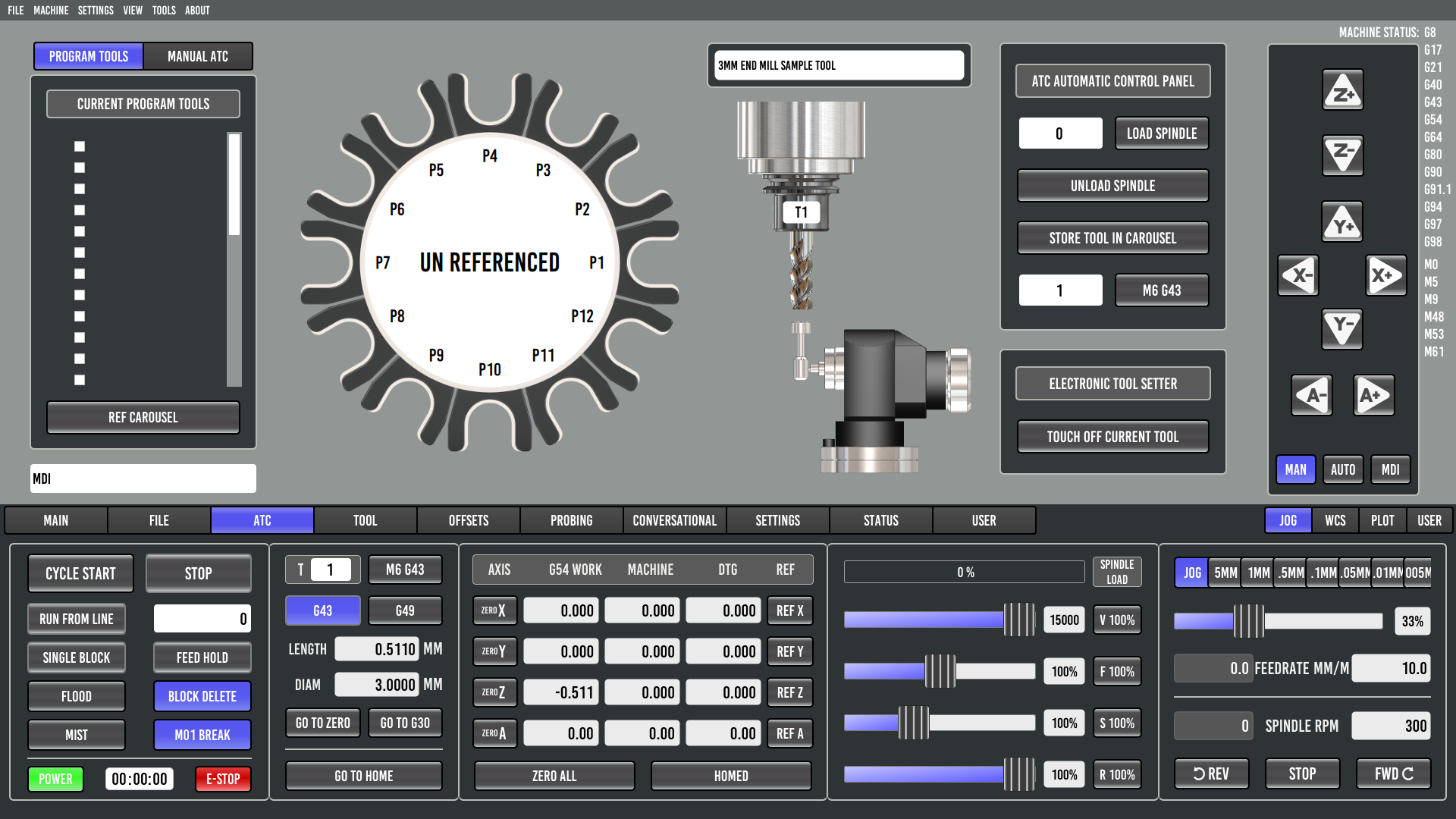

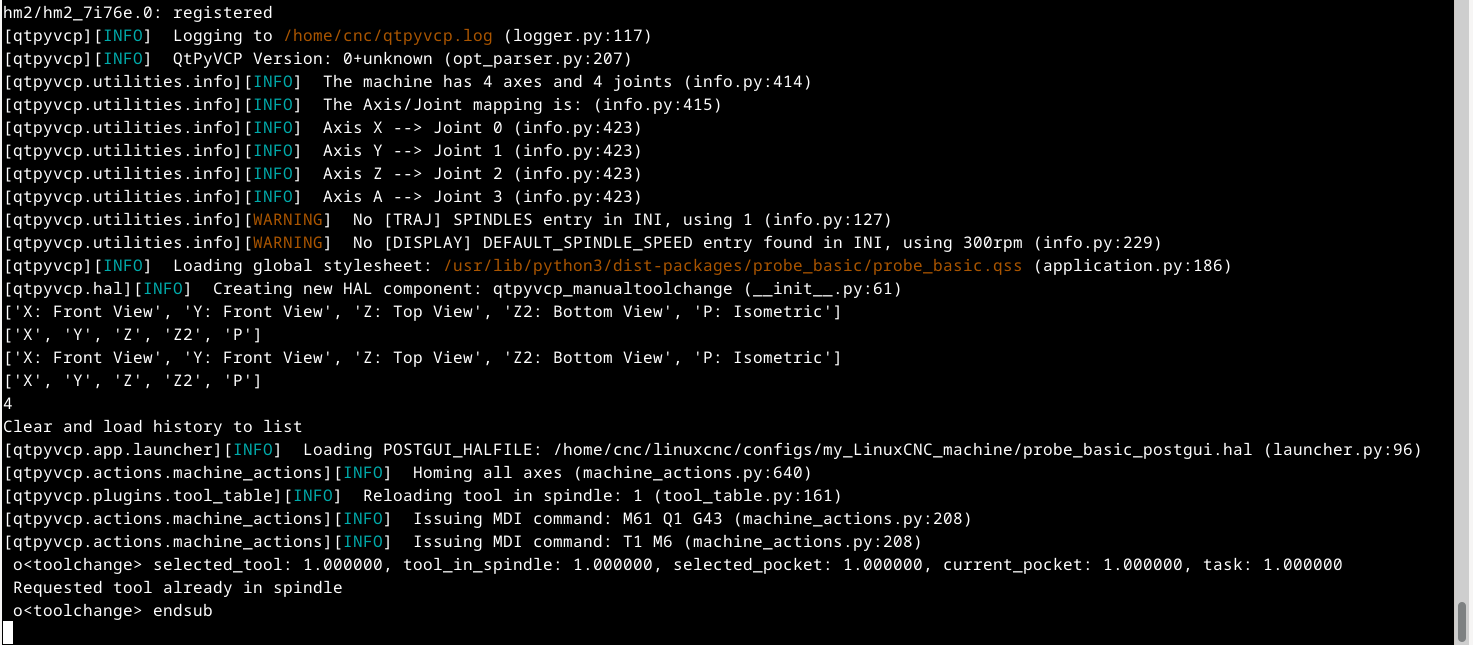

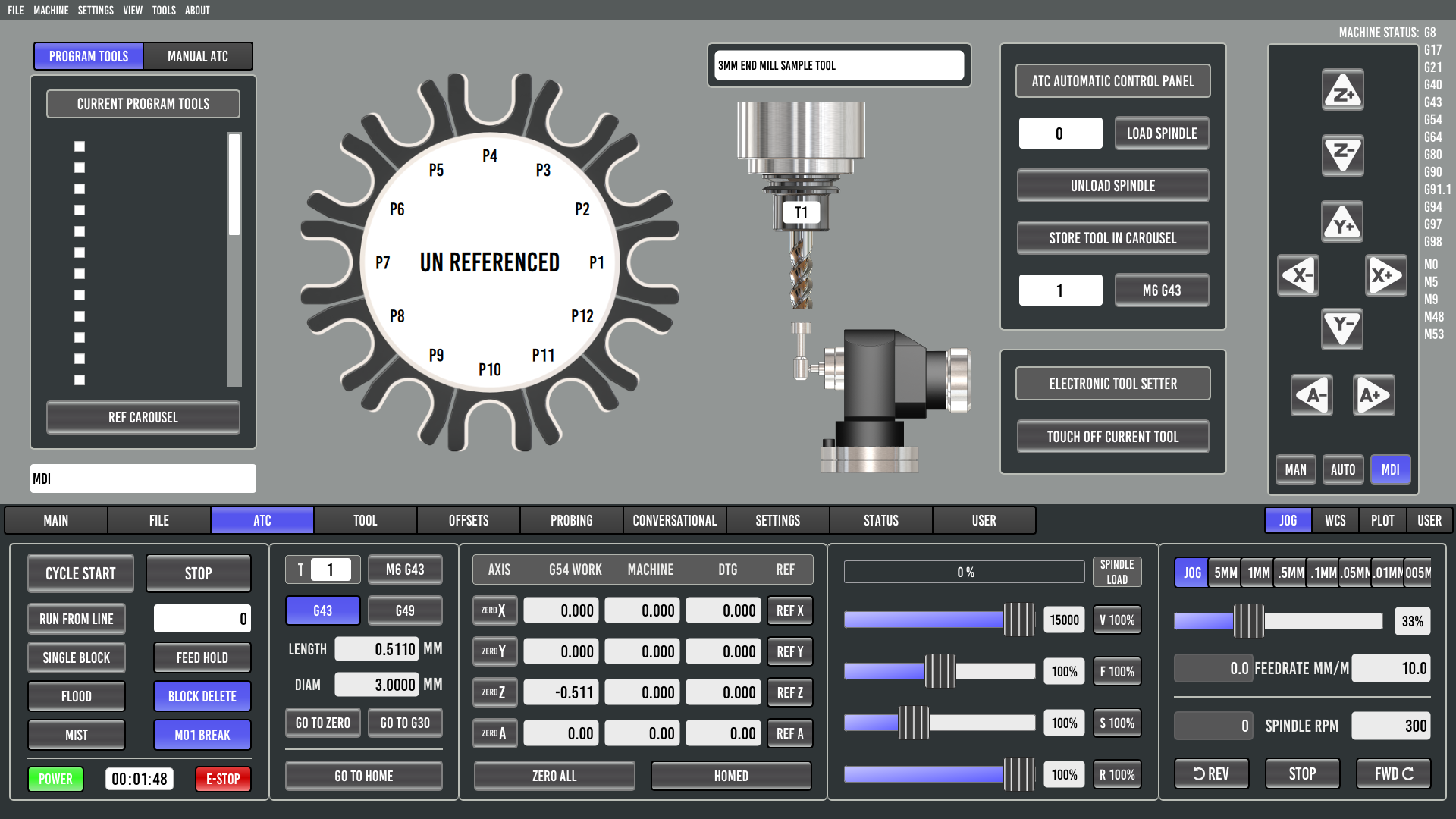

Replied by PeterSi on topic Probe Basic ATC Setup Problems

Probe Basic ATC Setup Problems

Category: QtPyVCP

- Str8jacket

- Str8jacket

03 Oct 2024 09:27

- snowgoer540

03 Oct 2024 09:19

Replied by snowgoer540 on topic Cut Recovery Not Consistently Triggering

Cut Recovery Not Consistently Triggering

Category: Plasmac

- MarkoPolo

- MarkoPolo

03 Oct 2024 09:06

Replied by MarkoPolo on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

- MennilTossFlykune

- MennilTossFlykune

03 Oct 2024 08:20

Replied by MennilTossFlykune on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

- Muecke

03 Oct 2024 07:01

- cmorley

- cmorley

03 Oct 2024 04:35

- Uthayne

- Uthayne

03 Oct 2024 02:44

Replied by Uthayne on topic Cut Recovery Not Consistently Triggering

Cut Recovery Not Consistently Triggering

Category: Plasmac

- PCW

03 Oct 2024 02:13

Replied by PCW on topic New project, litehm2: a hostmot2 port to linsn rv901t

New project, litehm2: a hostmot2 port to linsn rv901t

Category: Driver Boards

- spumco

- spumco

03 Oct 2024 02:13

Replied by spumco on topic [Solved] Probe Basic - program timer error

[Solved] Probe Basic - program timer error

Category: QtPyVCP

- AnkerFly

- AnkerFly

03 Oct 2024 01:51

Replied by AnkerFly on topic New project, litehm2: a hostmot2 port to linsn rv901t

New project, litehm2: a hostmot2 port to linsn rv901t

Category: Driver Boards

- spumco

- spumco

03 Oct 2024 01:28

Replied by spumco on topic [Solved] Probe Basic - program timer error

[Solved] Probe Basic - program timer error

Category: QtPyVCP

- jonsar

- jonsar

03 Oct 2024 00:16

Replied by jonsar on topic up grade fresh install

up grade fresh install

Category: Installing LinuxCNC

Time to create page: 1.055 seconds