Search Results (Searched for: )

- WKS-3D

11 Sep 2024 09:54

Probe Basic Lathe - Konfiguration von Axis übernehmen was created by WKS-3D

Probe Basic Lathe - Konfiguration von Axis übernehmen

Category: QtPyVCP

- shaying526

- shaying526

11 Sep 2024 09:51 - 14 Sep 2024 02:12

- machinedude

11 Sep 2024 09:49 - 11 Sep 2024 09:50

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- WKS-3D

11 Sep 2024 09:39

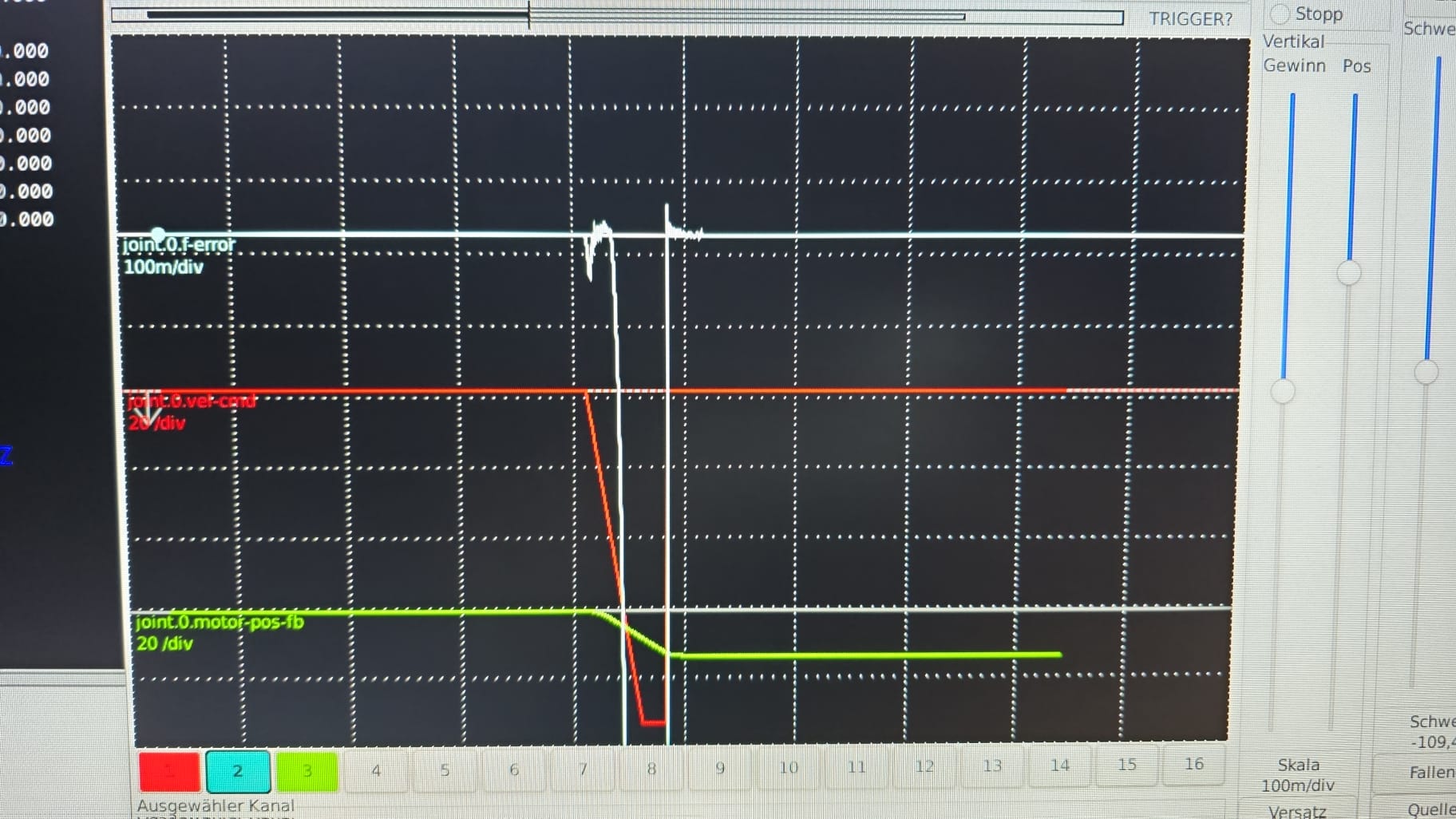

Replied by WKS-3D on topic Problem mit Servo und Glasmaßstab

Problem mit Servo und Glasmaßstab

Category: Deutsch

- MarkoPolo

- MarkoPolo

11 Sep 2024 09:18

Replied by MarkoPolo on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

- Yoshyluebeck

- Yoshyluebeck

11 Sep 2024 08:56 - 11 Sep 2024 09:03

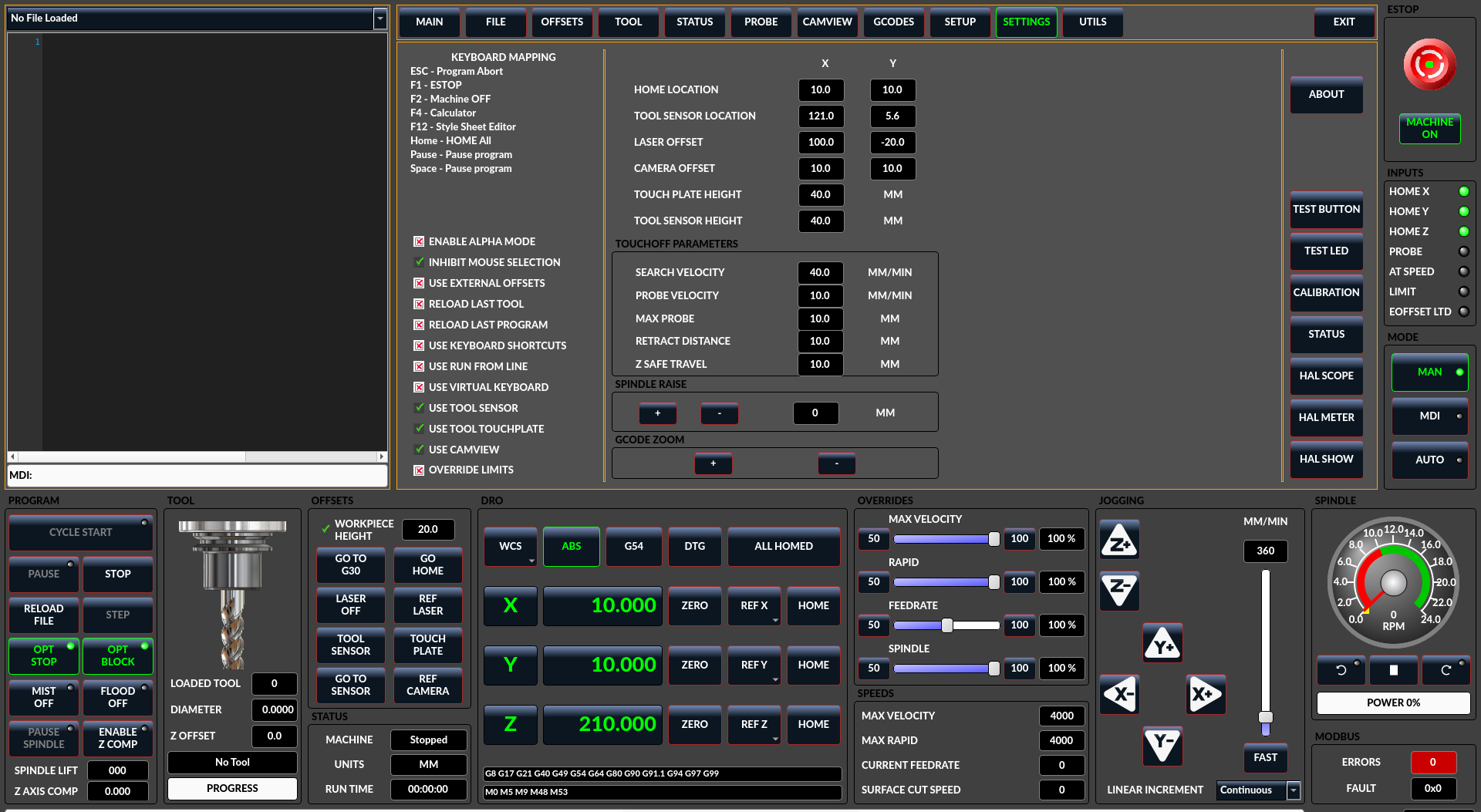

QT Dragon GoHome, ToolSensor and Go to Sensor was created by Yoshyluebeck

QT Dragon GoHome, ToolSensor and Go to Sensor

Category: Qtvcp

- Plasmanfm

- Plasmanfm

11 Sep 2024 08:50

Replied by Plasmanfm on topic Problem mit Servo und Glasmaßstab

Problem mit Servo und Glasmaßstab

Category: Deutsch

- WKS-3D

11 Sep 2024 07:22 - 11 Sep 2024 07:24

Replied by WKS-3D on topic Problem mit Servo und Glasmaßstab

Problem mit Servo und Glasmaßstab

Category: Deutsch

- Unlogic

- Unlogic

11 Sep 2024 05:38

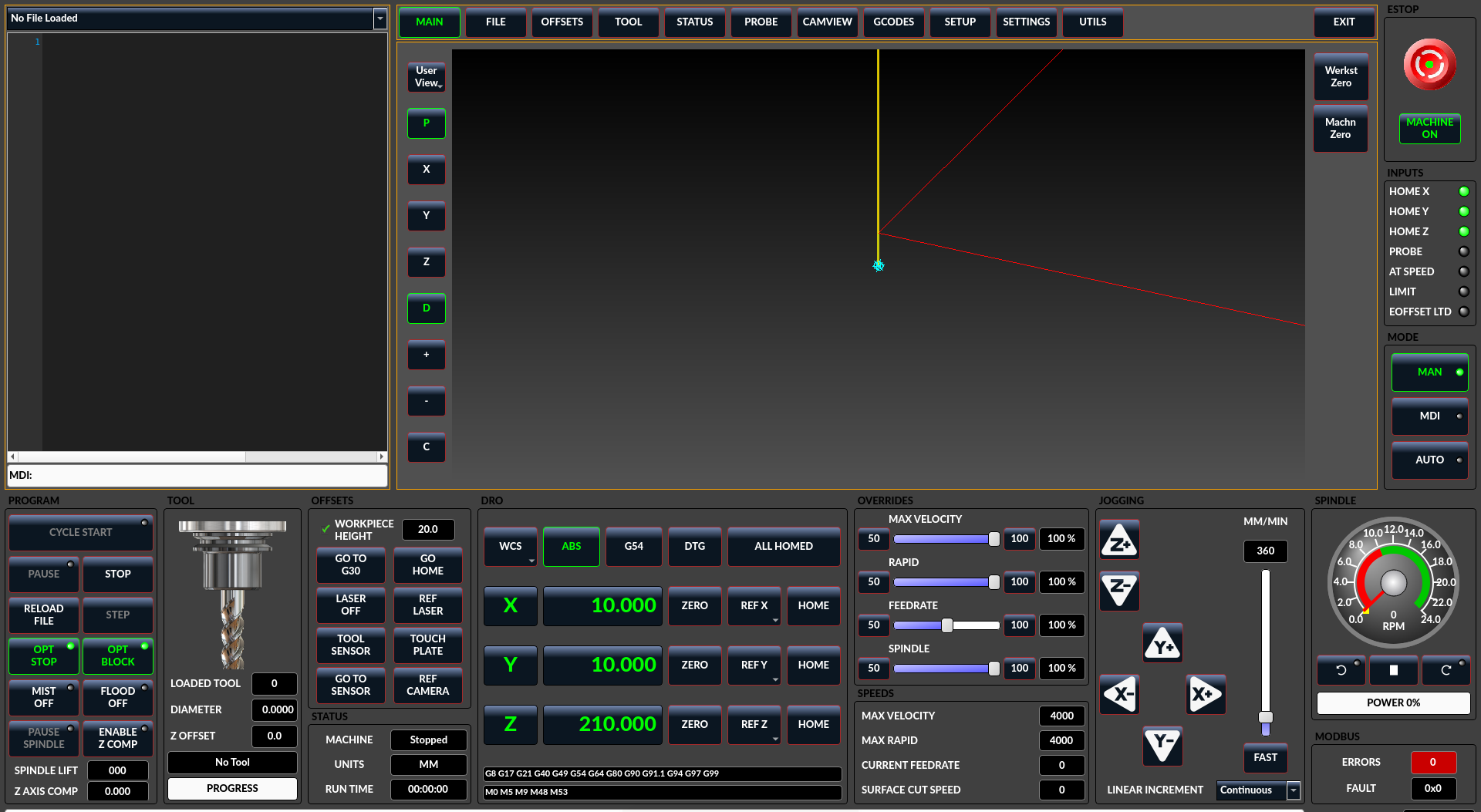

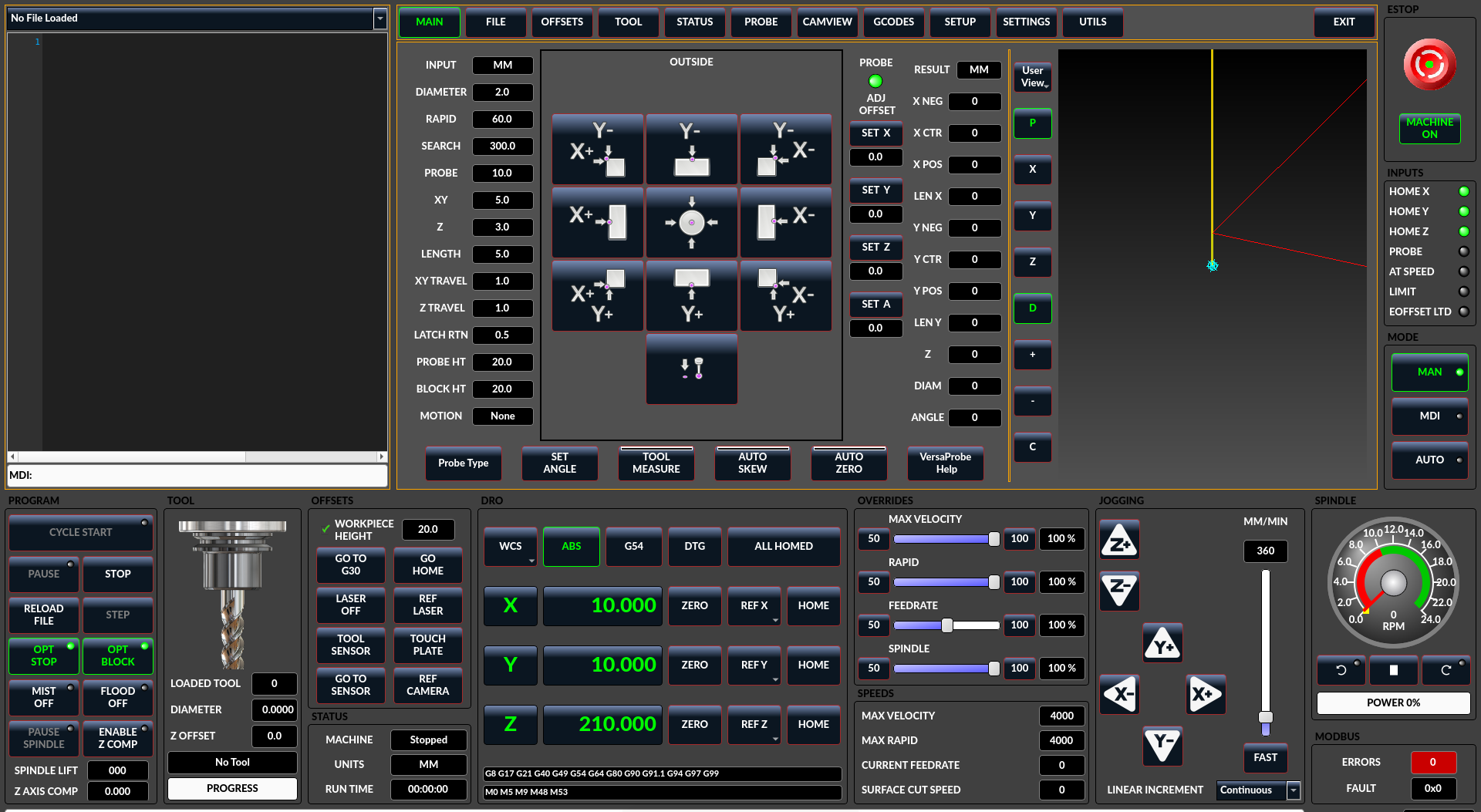

Replied by Unlogic on topic Probe Basic / Touch Probe

Probe Basic / Touch Probe

Category: General LinuxCNC Questions

- machinedude

11 Sep 2024 04:02 - 11 Sep 2024 07:25

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- PhilipME

11 Sep 2024 03:26 - 11 Sep 2024 03:27

Where the stepgen getting it's input from ? was created by PhilipME

Where the stepgen getting it's input from ?

Category: HAL

- cmorley

- cmorley

11 Sep 2024 01:47

- bertoldo

- bertoldo

11 Sep 2024 01:06

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- nwallace

- nwallace

11 Sep 2024 00:05

Replied by nwallace on topic Post GUI HAL not loading and "Bad character '[' used" error on E-Stop

Post GUI HAL not loading and "Bad character '[' used" error on E-Stop

Category: QtPyVCP

- SteveatSteelCut

- SteveatSteelCut

10 Sep 2024 23:56

Replied by SteveatSteelCut on topic Showstopper Plasma Cutter retrofit

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

Time to create page: 0.484 seconds