Search Results (Searched for: )

- Aciera

08 Mar 2025 12:39

Replied by Aciera on topic TAMAGAWA encoders model TS5661N132

TAMAGAWA encoders model TS5661N132

Category: General LinuxCNC Questions

- unknown

- unknown

08 Mar 2025 12:21

Replied by unknown on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- unknown

- unknown

08 Mar 2025 12:16

Replied by unknown on topic Raspi 5 touchscreen experience - recommendation

Raspi 5 touchscreen experience - recommendation

Category: Computers and Hardware

- gene_weber

08 Mar 2025 11:49

Replied by gene_weber on topic Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Category: Installing LinuxCNC

- Surmetall

08 Mar 2025 11:45

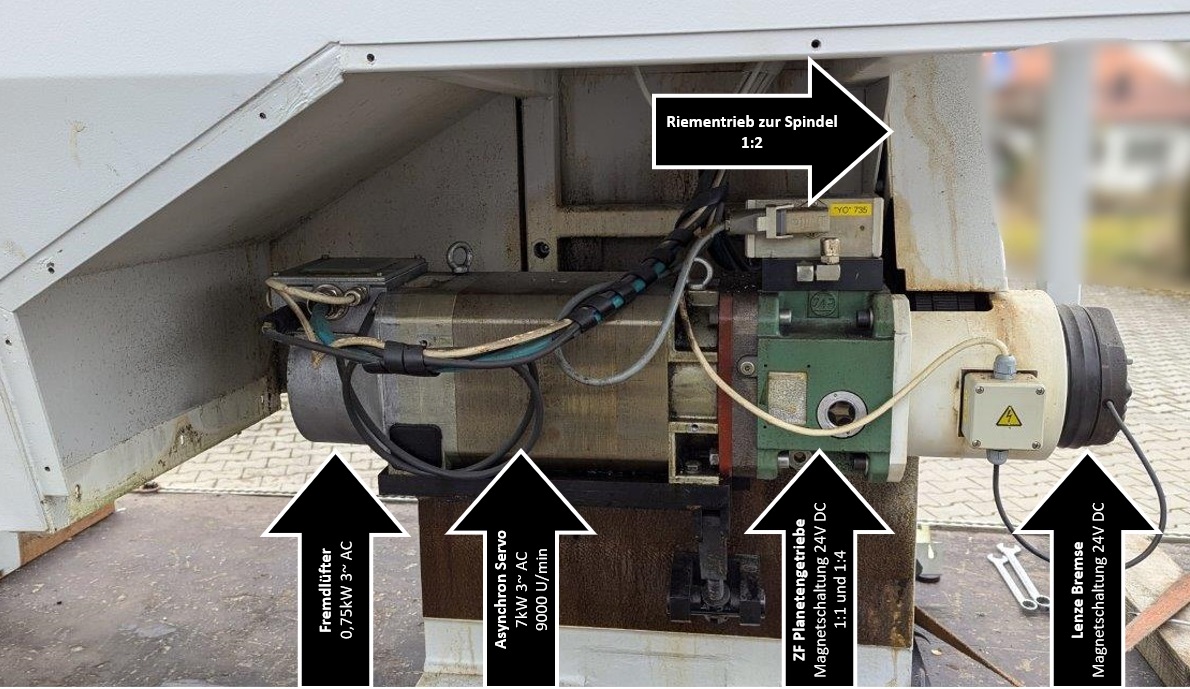

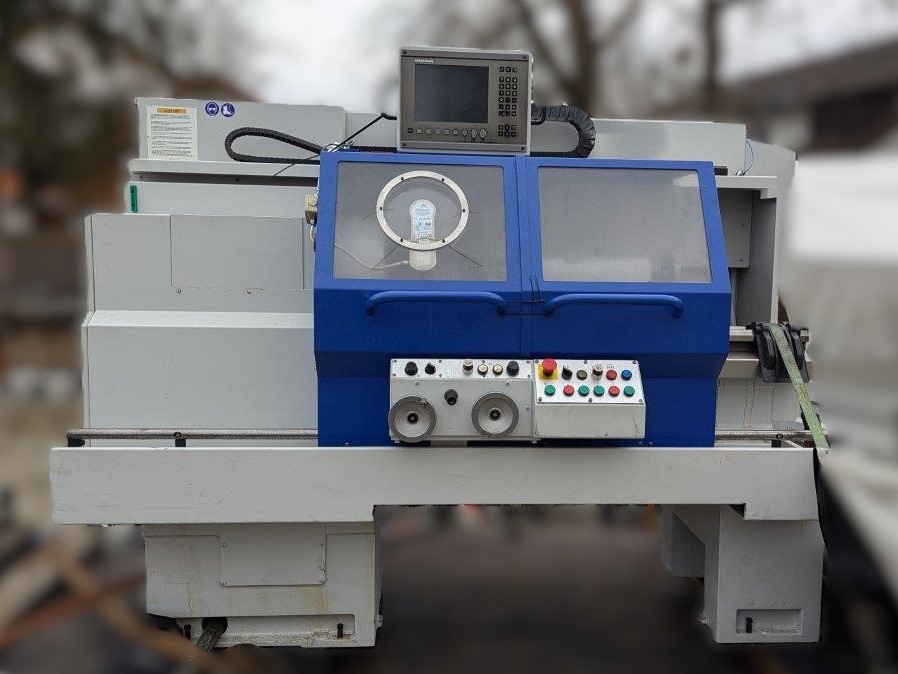

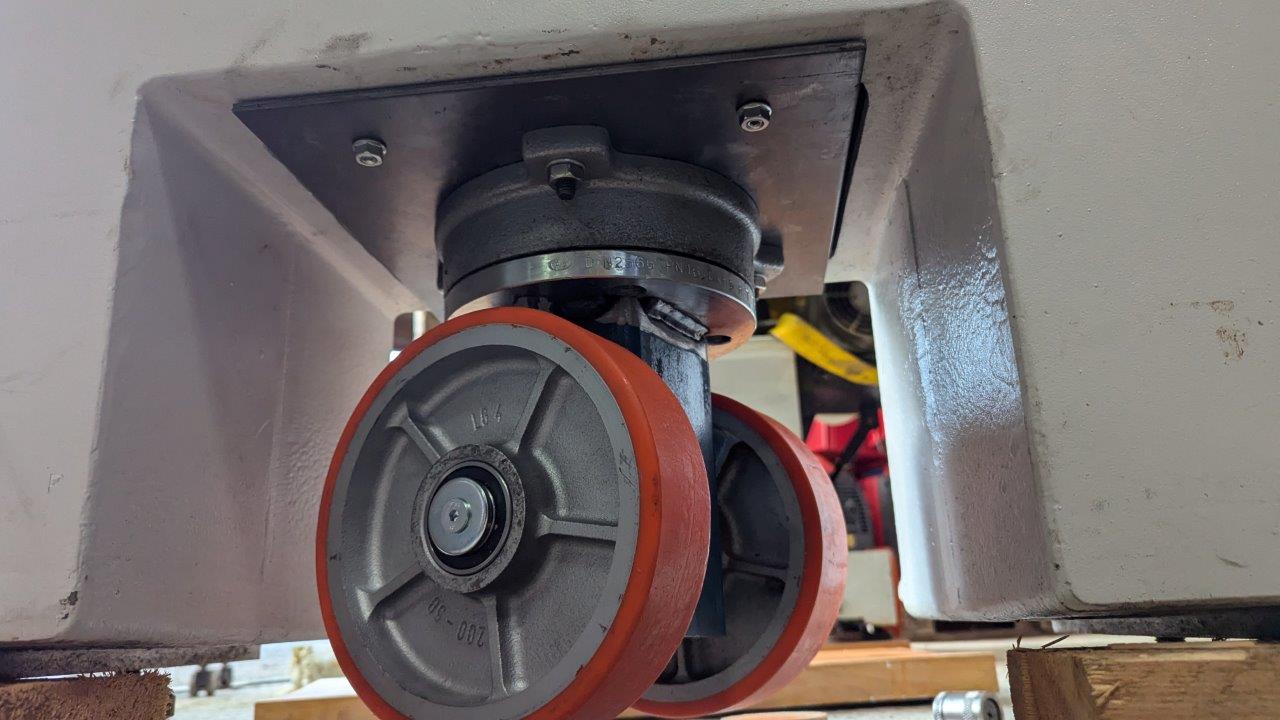

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Category: Turning

- Surmetall

08 Mar 2025 11:33 - 08 Mar 2025 11:36

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT? was created by Surmetall

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Category: Turning

- MillingMarvin

- MillingMarvin

08 Mar 2025 11:12 - 08 Mar 2025 12:48

Rigid Tapping - VFD and needed encoder ppm was created by MillingMarvin

Rigid Tapping - VFD and needed encoder ppm

Category: Milling Machines

- zz912

08 Mar 2025 10:14 - 08 Mar 2025 10:42

Replied by zz912 on topic Path to source code LCNC

Path to source code LCNC

Category: General LinuxCNC Questions

- Surmetall

08 Mar 2025 09:25

problem to start a new topic was created by Surmetall

problem to start a new topic

Category: Forum Questions

Time to create page: 0.598 seconds