Search Results (Searched for: )

- rodw

22 Jan 2025 19:53

Replied by rodw on topic Actual master on Debian 10

Actual master on Debian 10

Category: Installing LinuxCNC

- blazini36

- blazini36

22 Jan 2025 19:48

- Murphy

- Murphy

22 Jan 2025 19:42

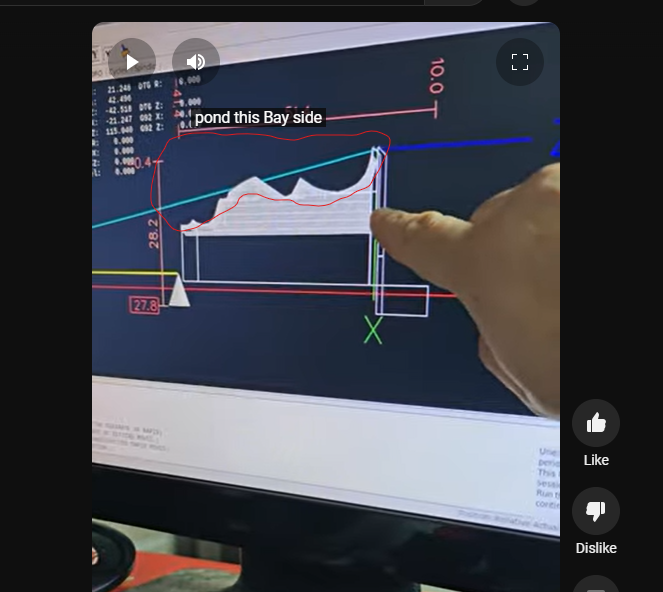

Replied by Murphy on topic Spindle location on the opposite side

Spindle location on the opposite side

Category: AXIS

- Clive S

- Clive S

22 Jan 2025 19:37

Replied by Clive S on topic Homing an axis moves away from home switch!

Homing an axis moves away from home switch!

Category: StepConf Wizard

- ihavenofish

- ihavenofish

22 Jan 2025 19:21

Replied by ihavenofish on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Murphy

- Murphy

22 Jan 2025 19:21

Replied by Murphy on topic Spindle location on the opposite side

Spindle location on the opposite side

Category: AXIS

- spumco

- spumco

22 Jan 2025 19:15

Replied by spumco on topic Spindle location on the opposite side

Spindle location on the opposite side

Category: AXIS

- machinedude

22 Jan 2025 19:09

Replied by machinedude on topic Black Friday Deal got me :)

Black Friday Deal got me :)

Category: Plasma & Laser

- papagno-source

- papagno-source

22 Jan 2025 19:00

Actual master on Debian 10 was created by papagno-source

Actual master on Debian 10

Category: Installing LinuxCNC

- Uthayne

- Uthayne

22 Jan 2025 18:58

Replied by Uthayne on topic Integrating a BCL-AMP capacitive sensor to LinuxCNC

Integrating a BCL-AMP capacitive sensor to LinuxCNC

Category: Plasma & Laser

- spumco

- spumco

22 Jan 2025 18:58

Replied by spumco on topic G33.1 synchronized tapping problem

G33.1 synchronized tapping problem

Category: General LinuxCNC Questions

- spumco

- spumco

22 Jan 2025 18:47

Replied by spumco on topic Spindle location on the opposite side

Spindle location on the opposite side

Category: AXIS

- Aciera

22 Jan 2025 18:31 - 22 Jan 2025 18:38

Replied by Aciera on topic Homing an axis moves away from home switch!

Homing an axis moves away from home switch!

Category: StepConf Wizard

- Aciera

22 Jan 2025 18:23

Replied by Aciera on topic rotation plane around y axis in g18

rotation plane around y axis in g18

Category: G&M Codes

Time to create page: 0.840 seconds