Search Results (Searched for: )

- endian

07 Jan 2026 08:13

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- grandixximo

07 Jan 2026 08:07

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- endian

07 Jan 2026 07:58 - 07 Jan 2026 08:07

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- JanCNC

- JanCNC

07 Jan 2026 07:53 - 07 Jan 2026 08:32

Replied by JanCNC on topic Servos drives directly start turning

Servos drives directly start turning

Category: General LinuxCNC Questions

- grandixximo

07 Jan 2026 07:42 - 07 Jan 2026 07:59

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- endian

07 Jan 2026 07:36

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- grandixximo

07 Jan 2026 07:24 - 07 Jan 2026 07:33

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

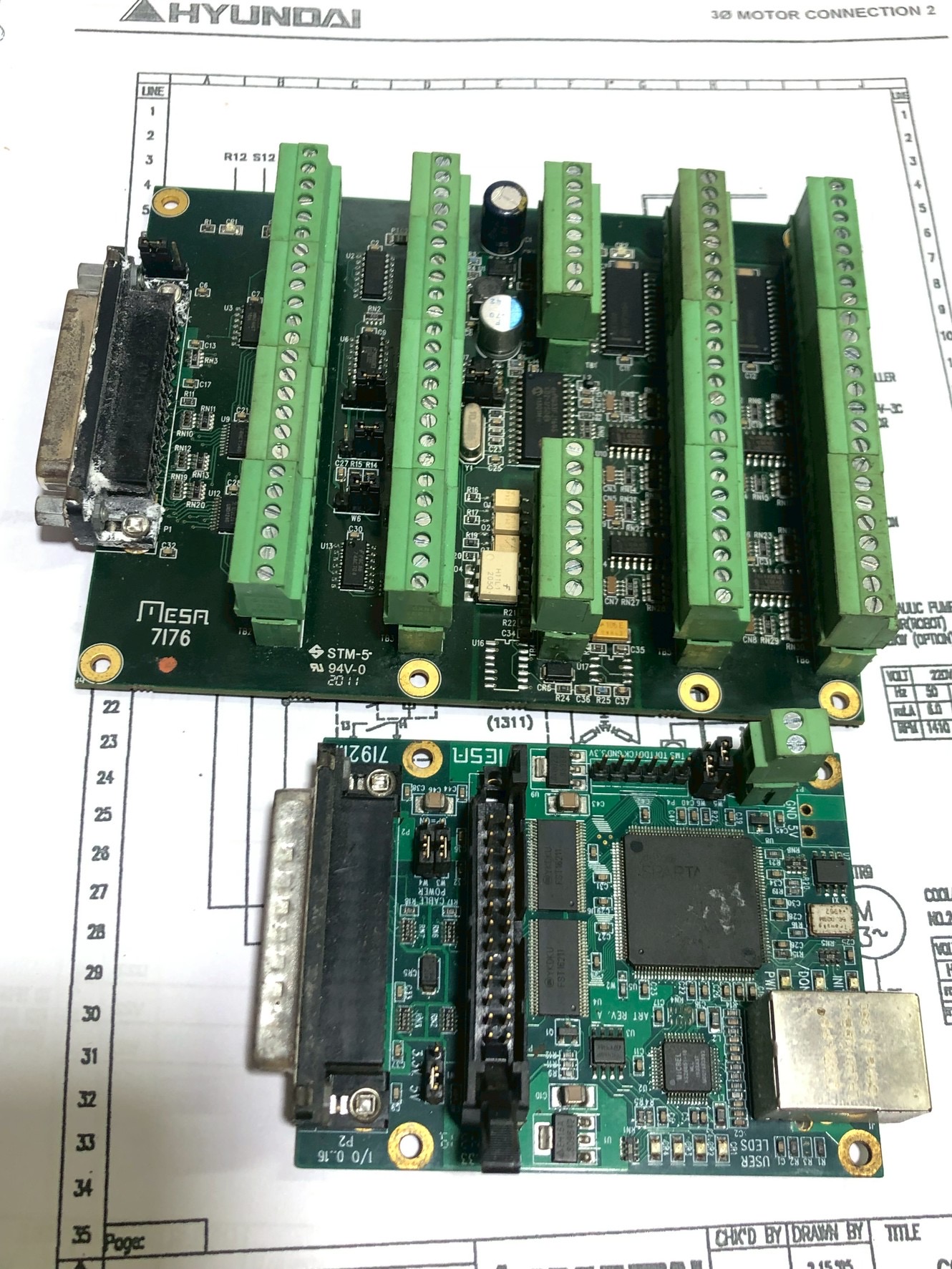

- SOLD

- SOLD

07 Jan 2026 06:54 - 07 Jan 2026 07:17

7i92M + 7i76 add PWM+PktUART was created by SOLD

7i92M + 7i76 add PWM+PktUART

Category: Driver Boards

- endian

07 Jan 2026 06:53

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- NWE

07 Jan 2026 06:41 - 07 Jan 2026 07:04

Replied by NWE on topic RPi CM5 on Mesa Ethernet 7i95

RPi CM5 on Mesa Ethernet 7i95

Category: General LinuxCNC Questions

- Mbrand1901

- Mbrand1901

07 Jan 2026 05:55 - 07 Jan 2026 07:58

Replied by Mbrand1901 on topic Retrofitting Deckel FP4ATC

Retrofitting Deckel FP4ATC

Category: Milling Machines

- grandixximo

07 Jan 2026 04:51

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- rodw

07 Jan 2026 03:33

Replied by rodw on topic 3D touch probe confusion

3D touch probe confusion

Category: Basic Configuration

- endian

07 Jan 2026 03:22 - 07 Jan 2026 03:35

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- PHILCOAST

07 Jan 2026 03:17

RPi CM5 on Mesa Ethernet 7i95 was created by PHILCOAST

RPi CM5 on Mesa Ethernet 7i95

Category: General LinuxCNC Questions

Time to create page: 0.506 seconds