Gmoccapy - A new screen for linuxcnc

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1930

- Thank you received: 394

On my lathe I am currently retrofitting. Two digits for the velocity and speed will not be enough if I am understanding you correctly. This machine is capable of 500 ips rapids and 200 ipm cutting. For the tool number I only see a need for two max. I will only use two digits. Maybe there is a way we can show the wear offset on the screen when using the Fanuc style lathe tool change patch? Not sure if thats possible as I am not sure there is anything in hall to use for that yet? Another suggestion would be buttons on the screen that can turn the mpg on and off as well as select what axis you are jogging. Maybe even an LED on the button showing active or not. Also any chance we could move the exit button to the setting screen like gscreen industrial so that the user can exit without a password?

Hallo Wes,

do you mean 500 ips ? that would be 30000 ipm!

That would be really fast!

OK with two digits I refer to the digits after the "dot" A velocity of 1234.1234 ipm would be shown as 1234.12, hoping that this is OK.

If you do use G95 (feed/rev) you will automatically get 4 digits for the feed label, but actual vel label will remain with two digits after the dot.

I have not taken a look on the FANUC style lathe patch! And at this development state I will not have time to do so. If there is a hal pin we can connect to, it will be easy to add a label to show the values. You just have to find a place for that!

May be there is a possibility to modify the tool editor widget? I think Chris has taken already a look to the FANUC patch.

Related to the Jog buttons, I do not see the need to have buttons on the screen to select the MGP axis. I have solved that until now with simple hal connections, so a axis will only move if I am in manual mode and the axis button on the MPG is pushed and the wheel is moving. Would it be enough to offer you a hal pin. If you set the pin height I could modify the background of the jog button, so it will acct like a LED. IMHO all this stuff should be done by hardware.

Why does the user need an password to exit?

He should be able on every time to change to manual mode and leave pressing exit!

A normal user will not be able to get to the settings screen, without a password, so IMHO it makes no sense to place an exit button there.

Norbert

Please Log in or Create an account to join the conversation.

- DaOne

-

- Offline

- Premium Member

-

- Posts: 155

- Thank you received: 6

do you mean 500 ips ? that would be 30000 ipm!

That would be really fast!

Yes you are correct its inches per minute. It was a typo on my part.

OK with two digits I refer to the digits after the "dot" A velocity of 1234.1234 ipm would be shown as 1234.12, hoping that this is OK.

If you do use G95 (feed/rev) you will automatically get 4 digits for the feed label, but actual vel label will remain with two digits after the dot.

Only time I can see using 4 digits is for something like rigid tapping.

I have not taken a look on the FANUC style lathe patch! And at this development state I will not have time to do so. If there is a hal pin we can connect to, it will be easy to add a label to show the values. You just have to find a place for that!

May be there is a possibility to modify the tool editor widget? I think Chris has taken already a look to the FANUC patch.

Its not that important. I just figured if it was easy enough it would be nice to display. I am sure down the road this patch will become integrated into master when all the bugs are worked out.

Related to the Jog buttons, I do not see the need to have buttons on the screen to select the MGP axis. I have solved that until now with simple hal connections, so a axis will only move if I am in manual mode and the axis button on the MPG is pushed and the wheel is moving. Would it be enough to offer you a hal pin. If you set the pin height I could modify the background of the jog button, so it will acct like a LED. IMHO all this stuff should be done by hardware.

The reason I need it because I use a touch screen and one MPG. It would allow me to switch between the X and Z axis easily. Maybe you could make a quick tutorial on how to add a simple button to the interface? If that's not possible maybe just some example (python) code and i will figure out the rest?

Why does the user need an password to exit?

He should be able on every time to change to manual mode and leave pressing exit!

A normal user will not be able to get to the settings screen, without a password, so IMHO it makes no sense to place an exit button there.

The reason I would like the exit in the settings menu (out of sight to the user and password protected) is because this machine will be used in a commercial setting with an employee at the controls. I do not wont that person to see or have access to anything but this screen (it will be in full screen mode). If I need to fix something I will use a physical key tied to a hall pin to access the settings mode and can quit linuxcnc from there.

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1930

- Thank you received: 394

The easiest way to make that is to add a user custom glade panel. Take a look at the gmoccapy_left_panel.iniThe reason I need it because I use a touch screen and one MPG. It would allow me to switch between the X and Z axis easily. Maybe you could make a quick tutorial on how to add a simple button to the interface? If that's not possible maybe just some example (python) code and i will figure out the rest?

It will load an additional button bar on the left side, and you will find with halshow a new component in Pins called v_buttonlist with pins for every button. You may use this ones to add all the functions you need. Do not forget to make the hal connections adding the -H option to the embedded tab command like shown in gmoccapy_sim_hardware_button.ini.

You can find very useful information here (specialy chapter 4):

Glade Virtual Control Panael

That is easy!The reason I would like the exit in the settings menu (out of sight to the user and password protected) is because this machine will be used in a commercial setting with an employee at the controls. I do not wont that person to see or have access to anything but this screen (it will be in full screen mode). If I need to fix something I will use a physical key tied to a hall pin to access the settings mode and can quit linuxcnc from there.

First you will have to open glade from a terminal after running . ./scripts/rip-environment

Open gmoccapy.glade, you will find it in linuxcnc-dev/share/gscreen/skins/gmoccapy

Mark the Exit button most left in the bottom bar, and select on the properties window left down the third tab, mark the sensitive option to False / No. Do not hide or erase the button, erasing it will crash the GUI and hiding it will move the botton buttons around, so you will get cosmetic problems;-)

Now search in the widget tree Left up the widget ntb_setup_page and mark it.

With the mouse placed over the tabs of the settings, moving the mouse wheel will bring you to the tab you wish to place the button,

lets go to hardware, because there is place left.

In the hal Pythot tool box click hal button and after that click on the place where you want to place the button.

In the propertys window you can change the label and modify some basics.

Go now to the signals tab in the properties window and click on clicked, the signal to add is: "on_btn_exit_clicked" you will have to tyoe that in, it will not be in the dropdown list.

Save everything, that's it!

Is someone else here who do wish an exit button on the settings page?

If so, I will add it.

IMHO there is no need, as I am planing to launch an industrial gmoccapy soon. I have had a lot of input to that on the German linuxcnc integrators meeting. But be aware it will not be able to operate without essential hardware. There will not be a Emergency button or a machine on button on the screen, there will not be any jogging button, increment selection only by hardware mode selectiopn by hardware switch and so on... but as far as I do plan with 5 axis and dro showing Abs Rel and DTG at once.

Norbert

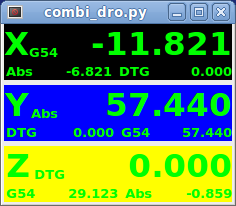

The attached image shows the combi_dro_widget, with X in Relative, Y in Absolut and Z in DTG Mode

Mode switching by clicking on the DRO. That will emit a signal so maintaining all DRO in the same state is easy, but not mandatory.

Imperial and Metric selection according to active GCode G20/G21.

Background colors are properties, (user can select the color for every mode)

so is the frontcolor, to distinguish between homed and not homed. (default red and green, but user selectable)

The Rel Label will change from G54 to any allowed coordinate system according to the active Gcode.

It is nearly finished, should it be integrated also in the standard gmoccapy GUI?

Please Log in or Create an account to join the conversation.

- DaOne

-

- Offline

- Premium Member

-

- Posts: 155

- Thank you received: 6

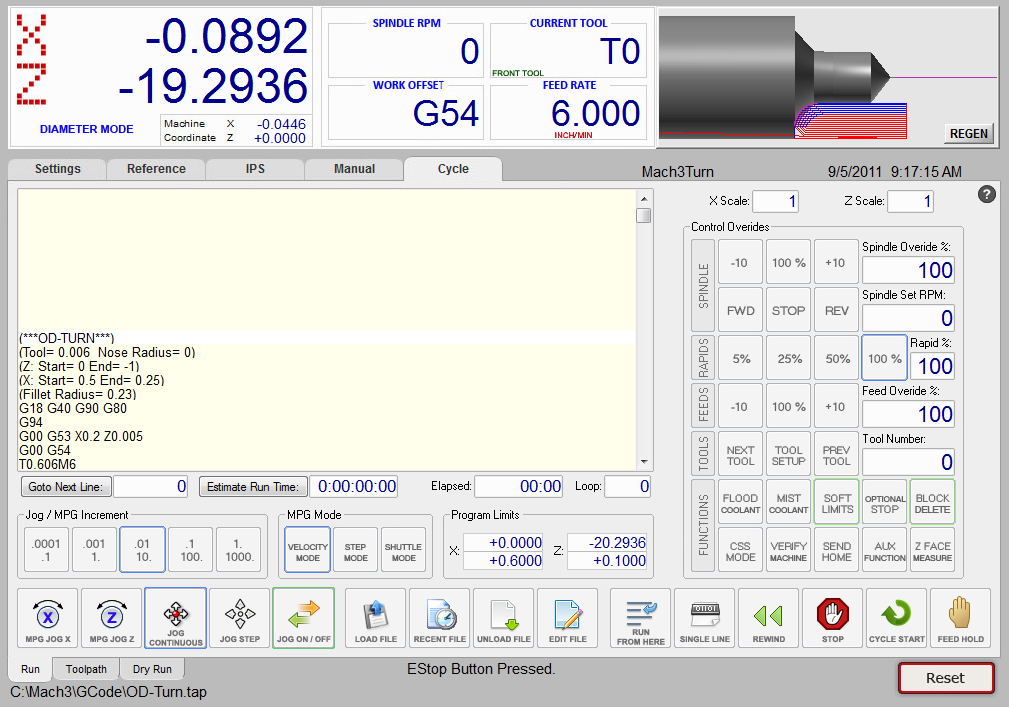

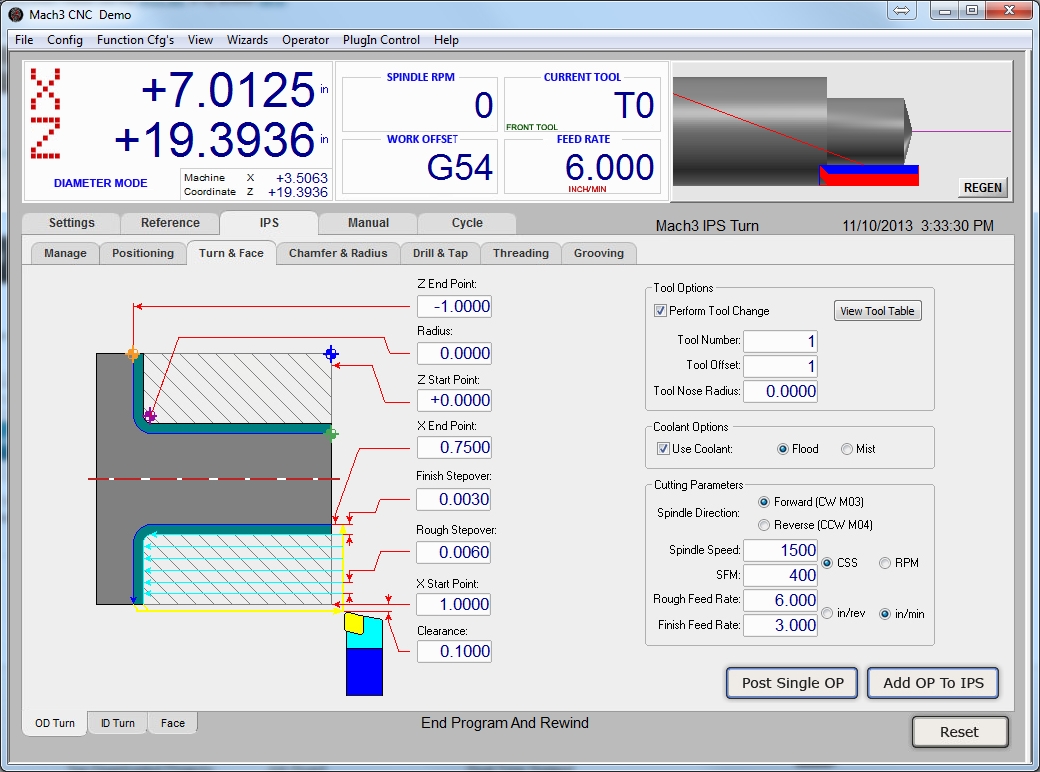

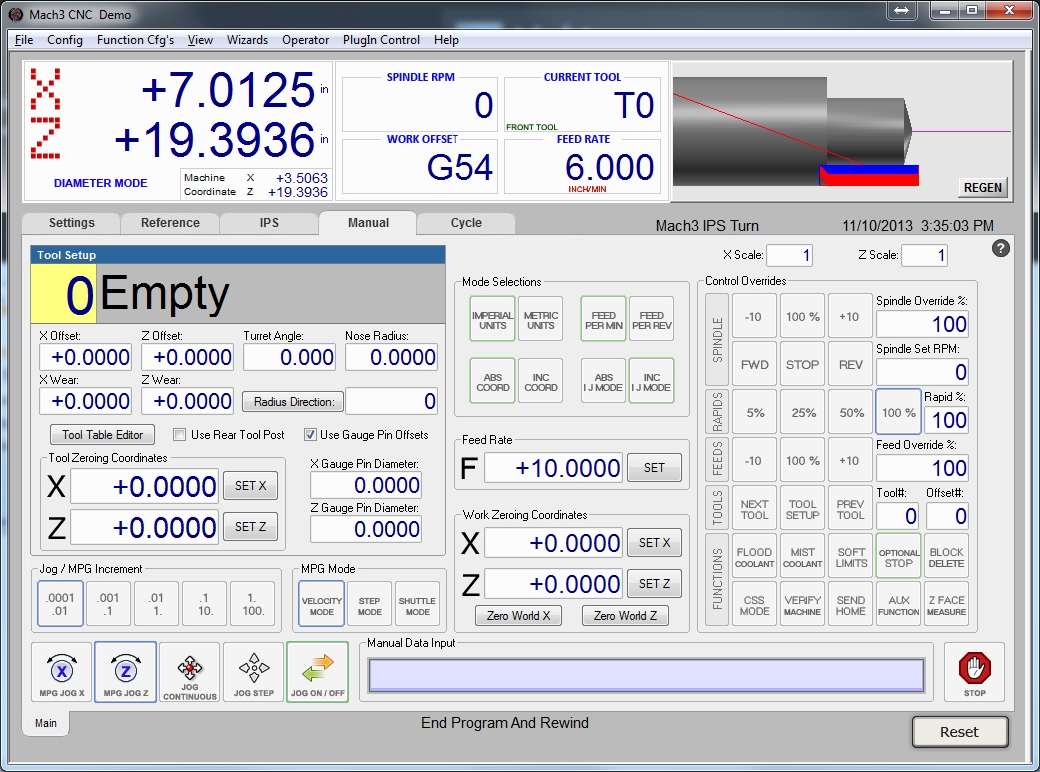

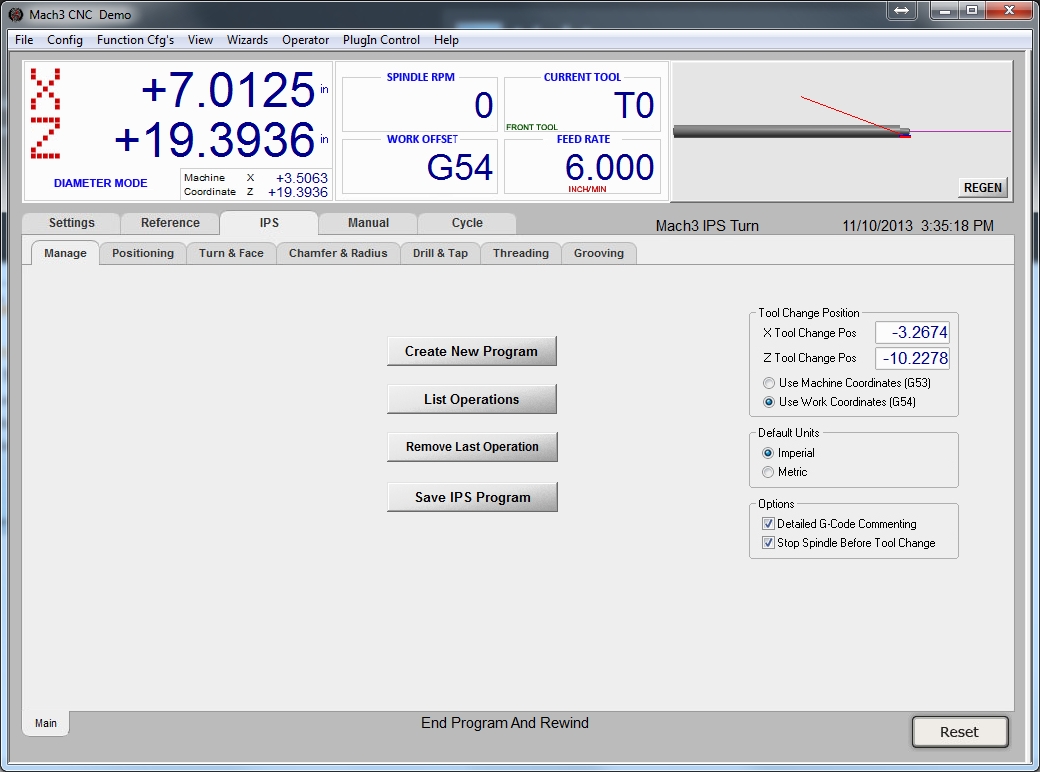

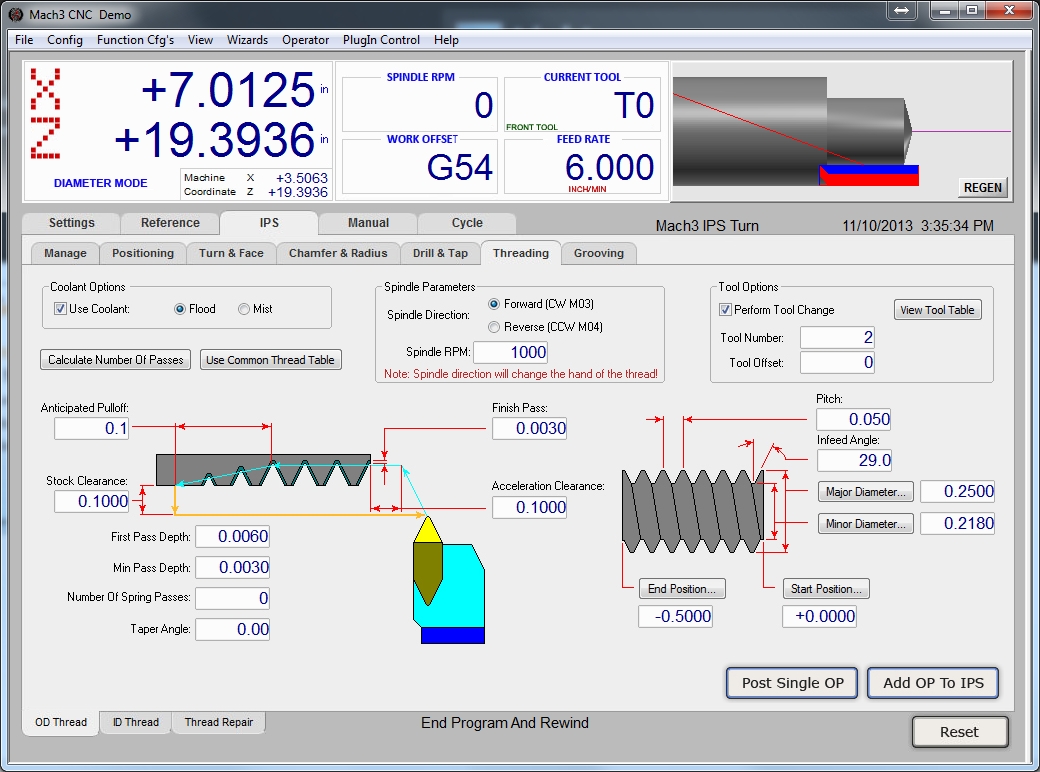

Thank you for your replys. I have been editing the files located in "/user/share/gscreen/skins/gmoccapy/" so I can play with the files in real time.. I have been reading all I can find on python and glade. I am determined to learn how to create my own screen in the future however yours is almost perfect for me so I am learning this by customizing it. I was working on a screenset for Mach3 a while back for the industrial lathe but due to Mach3s flaws I moved to LinuxCNC (so glad I did). Here is a screenshot of the Mach3 screen...

That comes to my next question. Are you familiar with IPS? Here is a PDF of what I am talking about..

www.haascnc.com/doclib/manual/es0610.pdf

Its basically an interactive program builder. I had a working model of this for mach3 but still learning python in order to do something such as this on LinuxCNC. Maybe someone who is proficient in coding had interest in such a thing? Just thought.

Can't wait to see your industrial screen! Need a beta tester?

Thank you for all your work on this.

Wes

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1930

- Thank you received: 394

whow, what a beautiful screen!

I do like the button part on the right, as it is very closed to industrial design, I am sure I will steel some of your Ideas

Are the Icon open Source, or open license? I would like to use some of them!

IPS, YES! Rene, German Guy has all the cycles nearly finished and I was able to show some examples on the German linuxcnc integrator meeting, generating code with gmoccapy, we generated 700.000 lines in less than 10 Seconds, but unfortunately the GUI crashes with that amount of information, because of the preview window. I am looking for a solution.

So the IPS will be called ShopfloorPro and will take some more time, just give us a year or so.

Norbert

What do you thing off the DRO?

Please Log in or Create an account to join the conversation.

- DaOne

-

- Offline

- Premium Member

-

- Posts: 155

- Thank you received: 6

The buttons for the most part are all mine. Ones that are not were public domain. Feel free to use them how you see fit. Also feel free to steal any part of my design. It will just help me achieve my goal of creating one that looks just like it a little faster.

Wes

Please Log in or Create an account to join the conversation.

- DaOne

-

- Offline

- Premium Member

-

- Posts: 155

- Thank you received: 6

Here is a link to the image files I made for my screen set.

dl.dropboxusercontent.com/u/75606622/IPS_IMAGES.zip

Wes

Please Log in or Create an account to join the conversation.

- DaOne

-

- Offline

- Premium Member

-

- Posts: 155

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- sliptonic

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 20

I've been playing with migrating my mill config from Axis to Gmoccapy and I'm really impressed. With the touchscreen, it's a pleasure to use. Thank you.

The only thing I haven't found is a way to toggle the spindle brake. If I need to customize this myself, I'd like to replace the coolant mist button with the brake toggle since I don't have mist.

Is there a guide to basic customization that I haven't found?

Thanks again!

The third way it to explain to me, why you need the spindle brake button on the screen and convince me to add the button, even if I do not know jet where to place it. In my knowledge there is no need for a special button, as motion does include the spindle-brake hal pin so the brake should be connected there.

Norbert

Hey Norbert,

I can't say that it belongs there. I just know that the equivalent button in Axis was useful to me. With my current config, the brake activates automatically with the spindle so to turn the spindle by hand (like with a dial indicator) I need to release the brake.

I'm not afraid of tackling some glade customization so if that's not typical workflow for others, I can look at the examples and give it a shot. Thanks.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Are you familiar with IPS? Here is a PDF of what I am talking about..

www.haascnc.com/doclib/manual/es0610.pdf

Its basically an interactive program builder.

I think that a lot of people use ngcgui for this: www.linuxcnc.org/docs/html/gui/ngcgui.html

I use my own macros, a similar interface to your version, but it doesn't actually generate any G-code, just runs a pre-programmed cycle. This suits the way that I work, generally making one-offs from a vague idea.

www.linuxcnc.org/index.php/english/forum...s/26550-lathe-macros

Please Log in or Create an account to join the conversation.