Another plasma component...

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1131

- Thank you received: 533

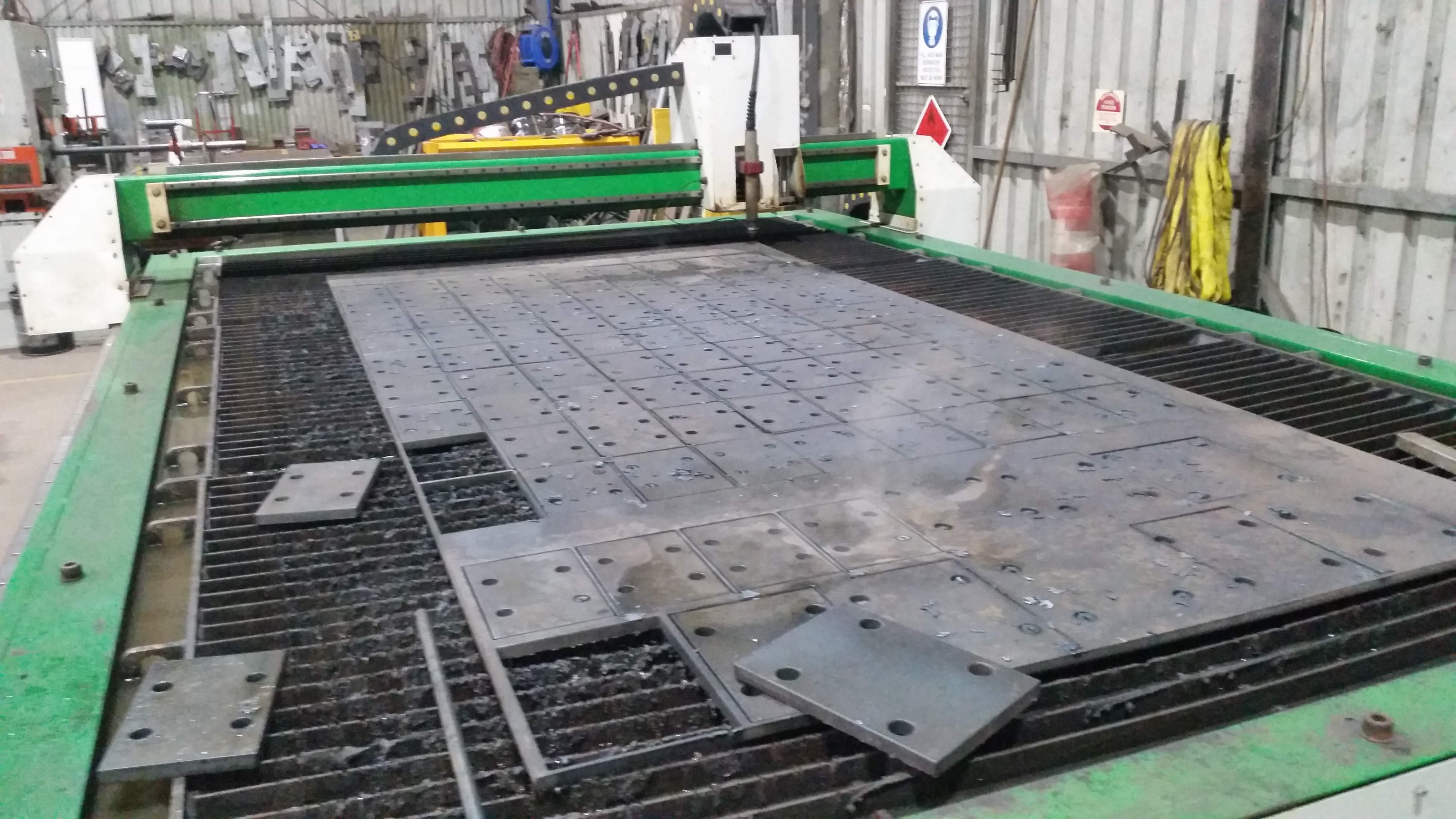

Everything worked out better than I thought,

My only thing I would change is after a cut the z axis moves to rapid height then for some reason moves up to the home position and then probes.

Why does it move upward from rapid height? I just feel this upward z axis movement is unnecessary and as far as I can tell does not achieve anything.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11527

- Thank you received: 3860

BTW PlasmaC is in 2.8 now so at least it will be in the next ISO release, albeit without the reverse-run feature but I don't think that is a show stopper.

Will there ever be a official ISO release with the Mint OS? I have grown very fond of the mint version of linux.

Chris Morley got permission from the Mint guys to use Mint in Linuxcnc's ISO's but I don't think the main dev team will make it. I saw BigJohnT say its not so important now becasue you can install the Mate desktop used by Mint on the Stretch ISO. But yes, I agree MInt is very nice!

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

It probably does that because I have never actually seen it cut...thefabricator03 wrote:

My only thing I would change is after a cut the z axis moves to rapid height then for some reason moves up to the home position and then probes.

Why does it move upward from rapid height? I just feel this upward z axis movement is unnecessary and as far as I can tell does not achieve anything.

I think you are right, I shall have a look and see what I can do.

BTW I have edited the doc about materialverter as you suggested, I haven't pushed the change yet.

Re the ISO, I would imagine that there will only be one distro.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I have just run a sim here and it doesn't show that behaviour. After an M5 if moves to safe height, rapids to next X/Y position, moves to probe height then probes.thefabricator03 wrote:

My only thing I would change is after a cut the z axis moves to rapid height then for some reason moves up to the home position and then probes.

Do you have a really high probe height, if not can you post a screenshot of your Config tab and the GCode several lines either side of an M5 between cuts.

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1131

- Thank you received: 533

[quote="phillc54" post=138793

Do you have a really high probe height, if not can you post a screenshot of your Config tab and the GCode several lines either side of an M5 between cuts.

Yes I checked it and my probe height was 100 but the safe height was 20,

I changes the safe height now the Z returns to its home after a cut,e.g cutting a hole then it will retract fully to 150mm then rapid then probe.

I am cutting a sheet that has 486 parts and it is taking a long time with all of the z axis movement. Is there a way to limit the height it retract to? instead of having it return home every time.

I have a long Z axis, I use that height sometimes to cut holes and slots into RHS so I still need to be able to have my Z height at 150mm.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

It only returns to Z max at the end of the job.

So with the figures you quoted, at the end of each cut it would rapid up 20 above the material (safe height), move to the start of the next cut, rapid to 100 above the Z minimum limit (probe height) then probe down.

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1131

- Thank you received: 533

I am trying to get the z axis to move quicker, I understand that the up and down movements of the z axis are controlled by the velocity and acceleration in the ini.

Please see attached you tube for a example of what is happening,

I have the probe speed set at 900 and the max speed setting set at 900,

How can I get it to move to the next step of motion quicker? As in when it moves up to safe height then move to next x y position and then starts the probe move.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Max Speed is read directly from the ini file.

Setup Speed is the speed that al Z moves are done at except probing and THC.

Probe Speed is the speed for probing down.

THC moves can be up to Max Speed if required (automatically).

If your Max Speed is 900 then that is what the ini file is set at.

Edit 1: BTW I have a new version that won't move up to probe height if probe height is higher than safe height. I haven't pushed it yet.

Edit 2: can you post your ini file

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11527

- Thank you received: 3860

So with plasma we do a trick and we can only do this becasue the THC and jogging of the Z axis are 100% mutually exclusive.

What I worked out before the external offsets was released we could double our ini file settings for vel and accel and apply

OFFSET_AV_RATIO = 0.5

That way the maximum vel and accel will be available for both probing and THC.

So Its possible you have got the ratio set to 0.5 but have not doubled your VEL and Accel.

After much testing and cursing over missed steps I have my 2 x vel and accel numbers for a NEMA 23 stepper set at 120 and 1400 (which is really 60 and 700)

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1131

- Thank you received: 533

As what Rod posted I had both sets of Velocity and Acceleration set to the same number, I did not read the ini closely enough and did not realize I needed to double the first set of numbers.

It cutting much faster, I just need to set up the THC off before the end of cut in sheetcam because the torch is diving at the end of cut and tripping the probe limit switch.

Please Log in or Create an account to join the conversation.