Feature Request

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

I think I fixed most of issues, plus:

Z goes to maximum height for a cut recovery from a rapid.

X/Y motion is slowed from the cut recovery buttons.

Good deal, thanks Phill! I'll give her a go after work today. Hopefully we got most of the bugs squished now!

Does it still require X0 and Y0 or did that get fixed?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

The new save dialog is also there.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

That is fixed as well, the only mandatory requirement is the F word.

The new save dialog is also there.

Sweet! Do you push these improvements to the mesh mode branch? I might spend some time there this weekend, I have some expanded mesh metal I've been meaning to cut...

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

I haven't touched that since being bogged down on this one. If it looks like we are nearly there I can make a combo branch on Friday for you.

Combo branch sounds good, just trying to keep it straight where we are so I don't move over to a different branch and report on issues that are already fixed.

I'll report back this evening and we can go from there!

Thanks again!

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

1. I tried taking out the Y0 of the ini, it still goes to X0 Y0. Maybe this is by design?

2. The shutter is back. I did confirm that it is not JUST the Y axis (as I had previously thought), it is for sure X and Y. It was harder for me to notice the X axis since it's lighter weight and only one stepper motor. Z may do it too, but I am using a ball screw, and it's extremely difficult to notice any shutter via that. I did watch the coupler for the Z axis very closely, and if it shutters, I can't notice it. I'd be reasonably confident saying it's only X and Y. Also, I confirmed that it does it at both ends of the soft limit travel for each axis. Exact steps to reproduce:

- Home table

- Load the job.ngc file I posted previously

- Start the job from home position

- Pause during the first M3 probe

- Click change consumables

- Press stop once the torch reaches the X0 Y0 position

- Move Y axis off of soft limits with Up arrow key

- Jog into the soft limits with down arrow key (not rapid)

I replicated this several times with the above method. Each time I restart LinxCNC, it's gone. Doing the above brings it back.

I should note for clarity that it does this with and without Y0 removed from the ini (the shutter had cropped up during the session in which I removed Y0 from the ini file, so I added it back to rule that possibility out).

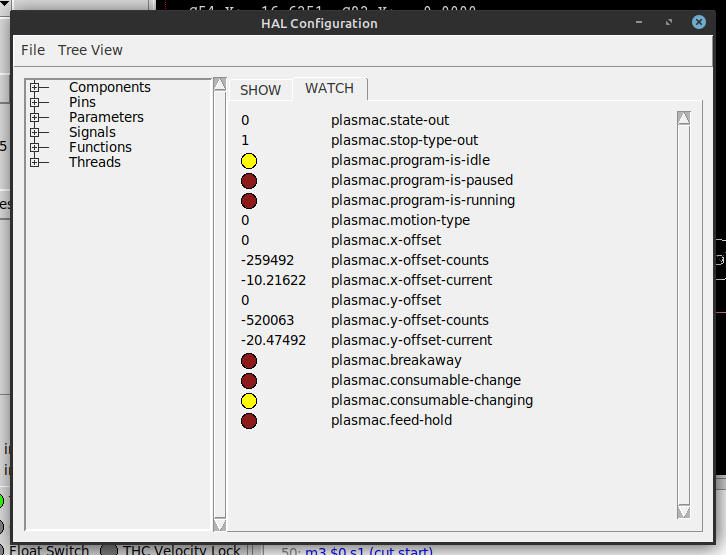

Here is a picture of the hal watch when the shutter is present:

Here is some videographic evidence

Normal bump against soft limits

Soft limit bump after table had too many cups of coffee

I think everything else seemed good to go otherwise.

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Yes, a missing axis in the parameters will default to zero.1. I tried taking out the Y0 of the ini, it still goes to X0 Y0. Maybe this is by design?

Would it be preferable to make it the current axis position?

This behaviour is expected with that workflow...2. The shutter is back. I did confirm that it is not JUST the Y axis (as I had previously thought), it is for sure X and Y. It was harder for me to notice the X axis since it's lighter weight and only one stepper motor. Z may do it too, but I am using a ball screw, and it's extremely difficult to notice any shutter via that. I did watch the coupler for the Z axis very closely, and if it shutters, I can't notice it. I'd be reasonably confident saying it's only X and Y. Also, I confirmed that it does it at both ends of the soft limit travel for each axis. Exact steps to reproduce:

Home table

Load the job.ngc file I posted previously

Start the job from home position

Pause during the first M3 probe

Click change consumables

Press stop once the torch reaches the X0 Y0 position

Move Y axis off of soft limits with Up arrow key

Jog into the soft limits with down arrow key (not rapid)

When you press stop, PlasmaC loses control of the axes and as your pic shows the offsets are still current. I am sure LinuxCNC doesn't take these offsets into account when it is detecting soft limits so your axis are really in an unknown position.

I will need to do some investigation into how we can get around this. We can't just reset the offsets to zero as the macine will then unexpectedly rapid move to where it should be.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

Yes, that's an excellent idea! From a safety standpoint, I'd think leaving an axis out of the ini should result in that axis not moving as it may be unexpected. I think setting it to the current position for the missing axis is a perfect solution!Would it be preferable to make it the current axis position?

Interesting, it makes me feel better though that it's not just me. I can imagine though that someone at some point might decide to stop the program for whatever reason in a chance consumable position.This behaviour is expected with that workflow...

When you press stop, PlasmaC loses control of the axes and as your pic shows the offsets are still current. I am sure LinuxCNC doesn't take these offsets into account when it is detecting soft limits so your axis are really in an unknown position.

I will need to do some investigation into how we can get around this. We can't just reset the offsets to zero as the macine will then unexpectedly rapid move to where it should be.

I'll run down and give it a go quick.I pushed a fix (I think)

Please Log in or Create an account to join the conversation.