Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

13 Feb 2017 11:11 - 13 Feb 2017 11:12 #87903

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well other than to pick up a box of M6 bolts to attach the linear rails and rack I have not done anything today.

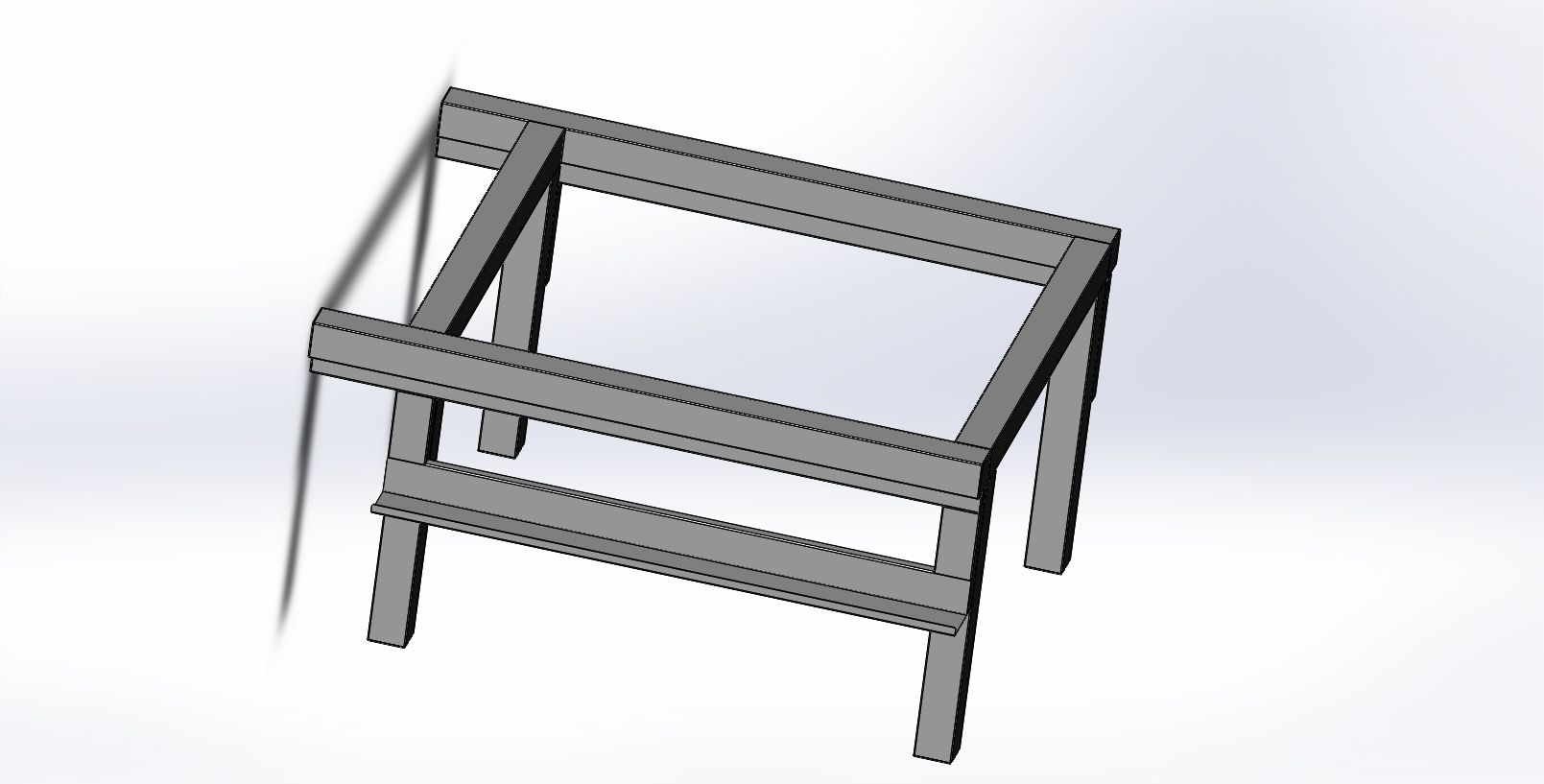

I have spent a few hours redesigning the table frame. You see, initially I had designed it so that the linear rail mounts bolted to the legs of the table. After I ordered the laser cut components, I realised this was a really dumb idea as there was no chance the legs could be dead square. So I decided to wait until I had the parts before reworking the design.

Anyway, here is where I'm at:

I've now got a 65 x 35mm RHS rail extending the full length of the side rail that the linear rail mount will eventually bolt to. The downside is I need to space out the cable tray by 50mm. With a bit of luck I'll be able to round up some 50mm x 100mm RHS to do this. I think this will still work out nicely because the rails will be recessed 50mm under the top rails and I'll end up with a 3mm gap between the top rail and the gantry end. This will mean the slides will end up being very well protected.

I think the only decision left is to decide how high the table will be. I see a lot of small tables about 900mm high (bench height) but most commercial tales are a lot lower, maybe 700mm. Any ideas in this regard?

Also does anybody have any experience with the pros and cons of casters on a plasma table? Does the table wobble too much if you use them to wheel the thing around?

I have spent a few hours redesigning the table frame. You see, initially I had designed it so that the linear rail mounts bolted to the legs of the table. After I ordered the laser cut components, I realised this was a really dumb idea as there was no chance the legs could be dead square. So I decided to wait until I had the parts before reworking the design.

Anyway, here is where I'm at:

I've now got a 65 x 35mm RHS rail extending the full length of the side rail that the linear rail mount will eventually bolt to. The downside is I need to space out the cable tray by 50mm. With a bit of luck I'll be able to round up some 50mm x 100mm RHS to do this. I think this will still work out nicely because the rails will be recessed 50mm under the top rails and I'll end up with a 3mm gap between the top rail and the gantry end. This will mean the slides will end up being very well protected.

I think the only decision left is to decide how high the table will be. I see a lot of small tables about 900mm high (bench height) but most commercial tales are a lot lower, maybe 700mm. Any ideas in this regard?

Also does anybody have any experience with the pros and cons of casters on a plasma table? Does the table wobble too much if you use them to wheel the thing around?

Last edit: 13 Feb 2017 11:12 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

19 Feb 2017 00:59 #88214

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

A bits been happening. I had a visit from a CNC zone member who tracked me down through a mate to check out my progress.

I've purchased the steel for the table on Saturday morning. I borrowed the work ute to collect it and then cut it down before I bought it home.

Stacked up in a corner of the garage.

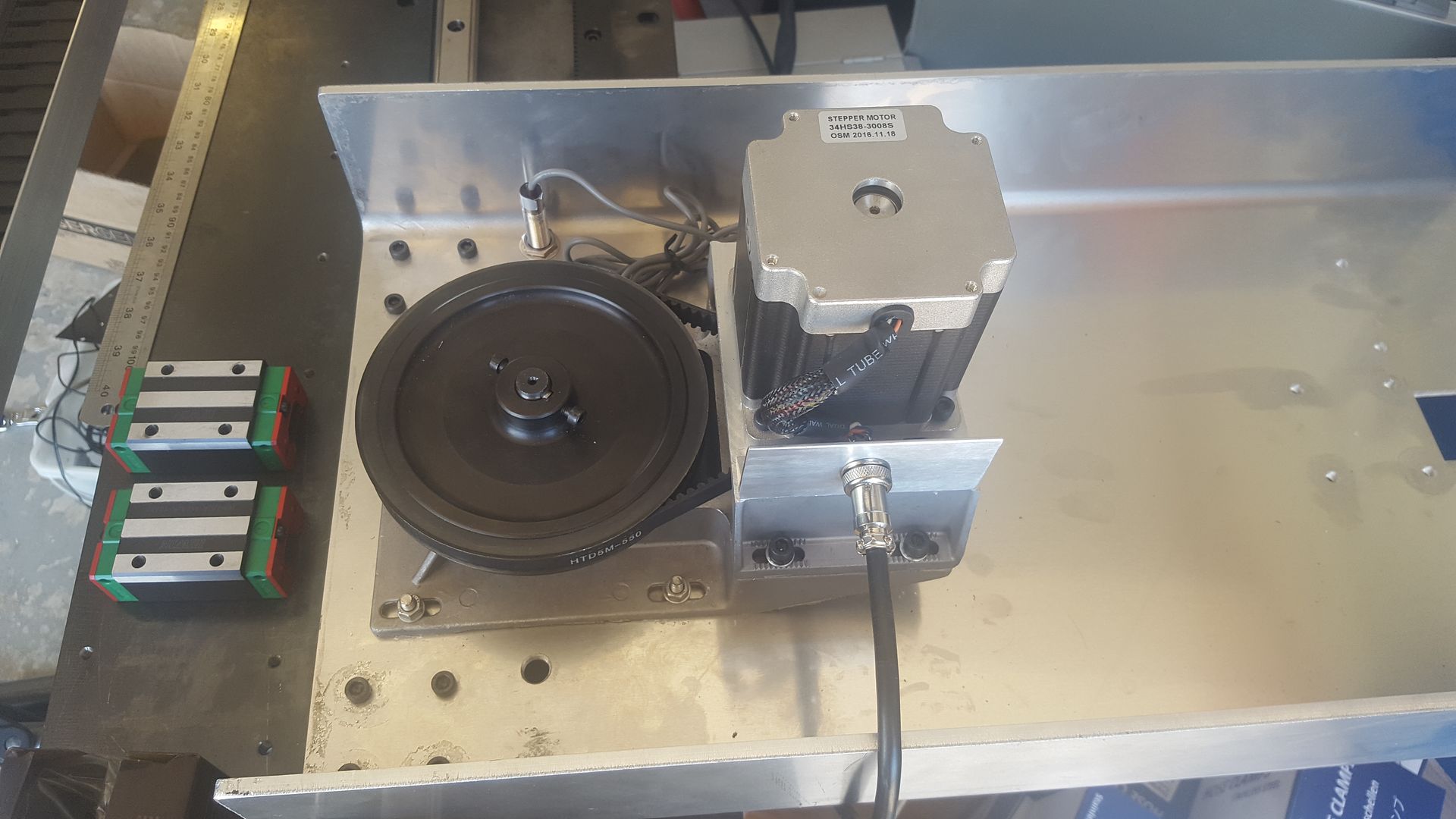

And I have one of the gantry axes running at last! Even if it is lying on its side.

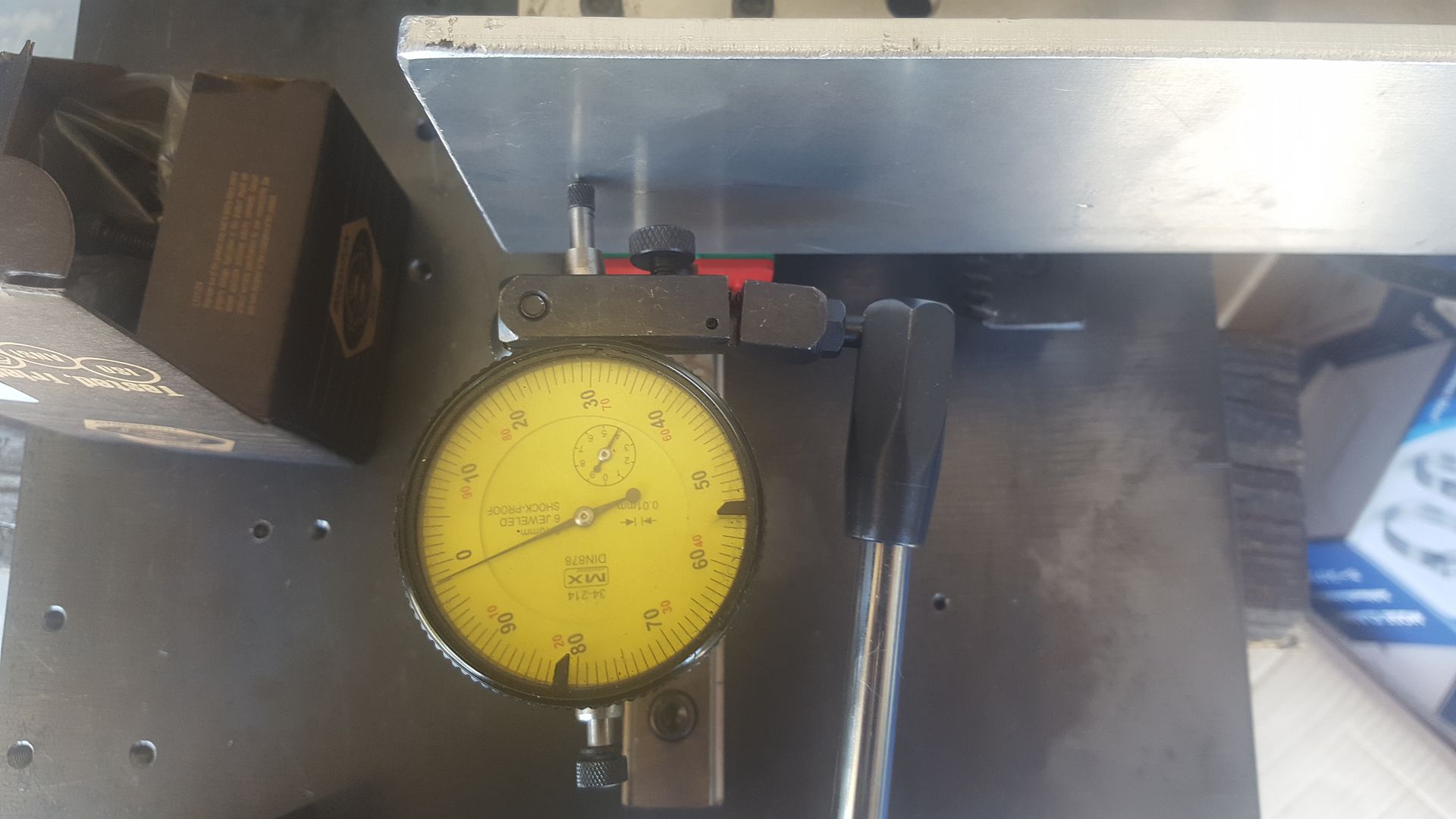

I had a lot of trouble calibrating the travel accurately. When I did the last rack and pinion, I just calculated the steps per mm and plugged it in for it to work perfectly. This rack and pinion was sold as a 1.25 module set and the actual readings were quite a way out so I did some calibration against a 1.0 m steel rule. Anyway, I got it working in the end. I sent it up and down the gantry for 20 metres using relatives moves in gcode

And the error was 0.02 mm

I think that at 0.001 mm per metre, that is about as good as it gets. I did not use the dial indicator when I calibrated it, so I might look at it again based on the findings above.

I wasted hours this morning becasue of my inexperience with Linux. Norbert had fixed a Gmocappy bug that I found and reported earlier in this thread sop I wanted to pull it down and install it for testing. Anyway, things went wrong and cncnoob came to the rescue so after taking ownership of my linuxcnc-dev folder that root had somehow stolen, I did a "make clean" followed by a "make" and it was all back on track.

I'm quite keen to try dewey's development branches with axis offsets and a couple of other features on git hub becasue it is fixing some of the unforseen issues the developers missed that needed to be fixed following merging of the joint axis code into master.

I have a few things to round up before I can tackle the table and the next couple of weekends are pretty full so progress will slow somewhat for a while. I need to have everything here to mount some casters to it as once its welded together, I won't be able to move it without them. As I plan to build it right where my wife parks her car, I gotta be careful! Anyway, at least I am still chipping away.

I've purchased the steel for the table on Saturday morning. I borrowed the work ute to collect it and then cut it down before I bought it home.

Stacked up in a corner of the garage.

And I have one of the gantry axes running at last! Even if it is lying on its side.

I had a lot of trouble calibrating the travel accurately. When I did the last rack and pinion, I just calculated the steps per mm and plugged it in for it to work perfectly. This rack and pinion was sold as a 1.25 module set and the actual readings were quite a way out so I did some calibration against a 1.0 m steel rule. Anyway, I got it working in the end. I sent it up and down the gantry for 20 metres using relatives moves in gcode

And the error was 0.02 mm

I think that at 0.001 mm per metre, that is about as good as it gets. I did not use the dial indicator when I calibrated it, so I might look at it again based on the findings above.

I wasted hours this morning becasue of my inexperience with Linux. Norbert had fixed a Gmocappy bug that I found and reported earlier in this thread sop I wanted to pull it down and install it for testing. Anyway, things went wrong and cncnoob came to the rescue so after taking ownership of my linuxcnc-dev folder that root had somehow stolen, I did a "make clean" followed by a "make" and it was all back on track.

I'm quite keen to try dewey's development branches with axis offsets and a couple of other features on git hub becasue it is fixing some of the unforseen issues the developers missed that needed to be fixed following merging of the joint axis code into master.

I have a few things to round up before I can tackle the table and the next couple of weekends are pretty full so progress will slow somewhat for a while. I need to have everything here to mount some casters to it as once its welded together, I won't be able to move it without them. As I plan to build it right where my wife parks her car, I gotta be careful! Anyway, at least I am still chipping away.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

19 Feb 2017 01:01 #88215

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I forgot. If anybody can help me with how to checkout a git branch, I'd appreciate the help!

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

19 Feb 2017 01:23 #88218

by Joco

Replied by Joco on topic Rods "Spaceship" Scratch built Plasma Cutter build

It's normally just:

git checkout <branch/tag name>

git checkout <branch/tag name>

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

19 Feb 2017 01:25 #88219

by rodw

Thanks James, do I do that in a new folder or does it go into the linuxcnc-dev folder?

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

It's normally just:

git checkout <branch/tag name>

Thanks James, do I do that in a new folder or does it go into the linuxcnc-dev folder?

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

19 Feb 2017 01:46 #88220

by Joco

Replied by Joco on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod - git does some magic so that you don't actually need to checkout different branches into different folders like you would do with svn.

However if you really wanted to have different folders then just clone the repo to another folder, cd to it and do a checkout to the branch you want.

git-scm.com/docs/git-checkout

However if you really wanted to have different folders then just clone the repo to another folder, cd to it and do a checkout to the branch you want.

git-scm.com/docs/git-checkout

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

19 Feb 2017 02:17 #88223

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

OK, so I did that

And then I thought the next step would be a git pull which failed

So how do I get the branch source?

plasma@plasma ~/linuxcnc-dev $ git checkout dgarr/external_offsets

M bin/.gitignore

Branch dgarr/external_offsets set up to track remote branch dgarr/external_offsets from origin.

Switched to a new branch 'dgarr/external_offsets'And then I thought the next step would be a git pull which failed

plasma@plasma ~/linuxcnc-dev $ git pull

remote: Counting objects: 179, done.

remote: Compressing objects: 100% (29/29), done.

remote: Total 29 (delta 28), reused 0 (delta 0)

Unpacking objects: 100% (29/29), done.

From git://git.linuxcnc.org/git/linuxcnc

+ c786d2d...3166ec6 dgarr/external_offsets -> origin/dgarr/external_offsets (forced update)

Auto-merging src/emc/task/emctaskmain.cc

Auto-merging src/emc/rs274ngc/gcodemodule.cc

Auto-merging src/emc/motion/control.c

CONFLICT (content): Merge conflict in src/emc/motion/control.c

Auto-merging docs/src/motion/external-offsets.txt

CONFLICT (add/add): Merge conflict in docs/src/motion/external-offsets.txt

Automatic merge failed; fix conflicts and then commit the result.So how do I get the branch source?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21211

- Thank you received: 7245

19 Feb 2017 02:26 #88224

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod, your build is looking niceeeeeeeee!

I offloaded a plasma frame build to a friend, metal worker, still waiting for it and last i saw it he had to cut it and weld it again due to a lot of mistakes.

Regards,

Tom

I offloaded a plasma frame build to a friend, metal worker, still waiting for it and last i saw it he had to cut it and weld it again due to a lot of mistakes.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

19 Feb 2017 02:27 #88225

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Ahh, I think I get it now, I see the external_offsets sims in the linuxcnc-dev folders now so I guess its just a matter of running make again! Lets see what happens after it finishes building

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

19 Feb 2017 05:27 #88232

by rodw

Thanks Tommy. I am a bit worried that might happen to me!

Anyway, I was able to install Dewey's external offsets code, but I don't really understand it yet.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod, your build is looking niceeeeeeeee!

I offloaded a plasma frame build to a friend, metal worker, still waiting for it and last i saw it he had to cut it and weld it again due to a lot of mistakes.

Regards,

Tom

Thanks Tommy. I am a bit worried that might happen to me!

Anyway, I was able to install Dewey's external offsets code, but I don't really understand it yet.

Please Log in or Create an account to join the conversation.

Time to create page: 0.149 seconds