- LinuxCNC

- General LinuxCNC Questions

- Machine has been working great but my Proma THC is responding slow when cutting

Machine has been working great but my Proma THC is responding slow when cutting

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

21 Feb 2020 02:33 #158082

by TexasCNC

Replied by TexasCNC on topic Machine has been working great but my Proma THC is responding slow when cutting

the settings helped it respond quicker now which is good. Now the torch is dancing up and down it cuts but it goes up and down while cutting. Is this cause I am getting moisture in the torch I see the my electrodes get swirly real quick?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7279

21 Feb 2020 11:54 #158122

by tommylight

Replied by tommylight on topic Machine has been working great but my Proma THC is responding slow when cutting

Lover the thc speed in Linuxcnc. Check the PlasmaC manual.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

22 Feb 2020 02:23 #158174

by TexasCNC

Replied by TexasCNC on topic Machine has been working great but my Proma THC is responding slow when cutting

Lower the speed for the THC tab?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7279

22 Feb 2020 08:48 #158180

by tommylight

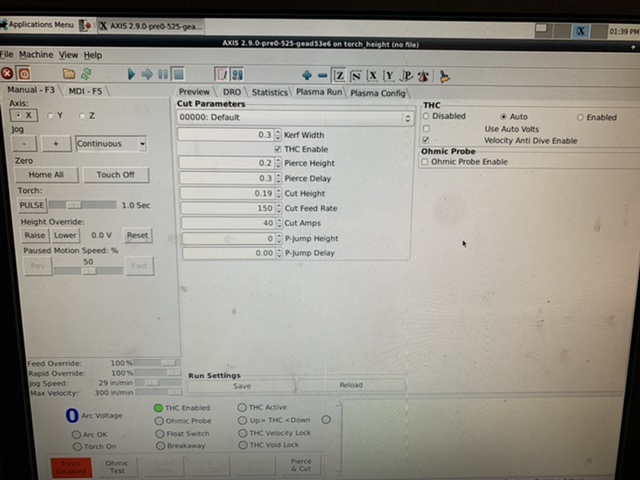

If using toma_thc config, that setting is on the right side panel, can not recal exact name but the initial value should be 0.200,

Replied by tommylight on topic Machine has been working great but my Proma THC is responding slow when cutting

Yes, lower the THC speed in the "RUN " tab or panel if you are using PlasmaC.Lower the speed for the THC tab?

If using toma_thc config, that setting is on the right side panel, can not recal exact name but the initial value should be 0.200,

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

23 Feb 2020 00:43 #158261

by TexasCNC

Replied by TexasCNC on topic Machine has been working great but my Proma THC is responding slow when cutting

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7279

23 Feb 2020 09:25 #158285

by tommylight

Replied by tommylight on topic Machine has been working great but my Proma THC is responding slow when cutting

Those are the same pictures.

The other tab ?

The other tab ?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

23 Feb 2020 09:44 #158287

by phillc54

Replied by phillc54 on topic Machine has been working great but my Proma THC is responding slow when cutting

On the other thread.

forum.linuxcnc.org/38-general-linuxcnc-q...cuts?start=10#158262

forum.linuxcnc.org/38-general-linuxcnc-q...cuts?start=10#158262

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

23 Feb 2020 11:25 #158295

by TexasCNC

Replied by TexasCNC on topic Machine has been working great but my Proma THC is responding slow when cutting

Yes they are just didn’t want to ask different question on one thread that’s why.

The following user(s) said Thank You: phillc54, tommylight

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

22 Mar 2020 17:58 - 22 Mar 2020 18:57 #161126

by TexasCNC

Replied by TexasCNC on topic Machine has been working great but my Proma THC is responding slow when cutting

I just got a machine torch for my plasma the sl100sv for my thermal dynamics CM52. And it’s awesome the delay for torch fire is very fast but when I am cutting 14g it’s good but when I move up to 1/4 plate I need more pierce delay and after setting the delay to .5 seconds on sheetcam it doesn’t do any difference on the torch fire. Then I set the delay to 1.5s and still the same thing there is no delay when running a cut. Is there is something in the linuxcnc post processor that needs to be edited so it can use the sheetcam settings? Is there somewhere in the GUI that I can adjust to reflect the Pierce delay I need? I know my post processor has the command to use sheetcam settings on cutting speed.

Last edit: 22 Mar 2020 18:57 by TexasCNC.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

22 Mar 2020 20:52 #161138

by rodw

Replied by rodw on topic Machine has been working great but my Proma THC is responding slow when cutting

The cut settings including pierce delay come from Plasmac materials settings. About the only thing used from Sheetcam is the tool number and feed rate.

There is a materialverter.py script that exports a Saved Sheetcam toolset to Plasmac. Did you use that?

Does Plasmac have a material set up? Does the material number agree with what is in Sheetcam?

There is a materialverter.py script that exports a Saved Sheetcam toolset to Plasmac. Did you use that?

Does Plasmac have a material set up? Does the material number agree with what is in Sheetcam?

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Machine has been working great but my Proma THC is responding slow when cutting

Time to create page: 0.343 seconds