Search Results (Searched for: )

- tommylight

02 Sep 2024 21:19

- JetForMe

02 Sep 2024 21:09 - 02 Sep 2024 21:09

Inspect current G64 parameters? was created by JetForMe

Inspect current G64 parameters?

Category: General LinuxCNC Questions

- Carsten

- Carsten

02 Sep 2024 20:14

- PCW

02 Sep 2024 20:03

- cmorley

- cmorley

02 Sep 2024 19:50

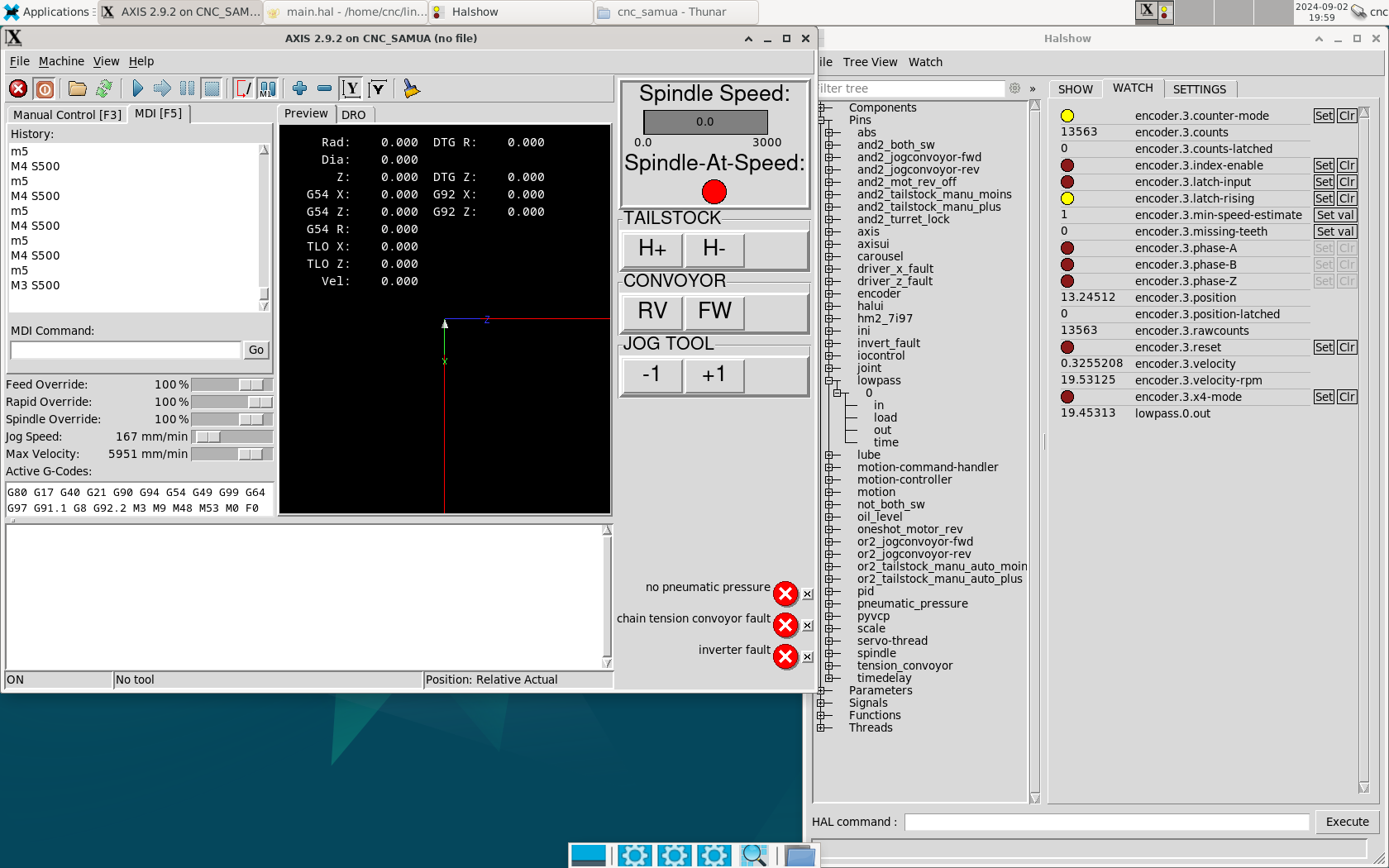

- greg23_78

- greg23_78

02 Sep 2024 19:46 - 02 Sep 2024 19:49

encoder.N.velocity-rpm was created by greg23_78

encoder.N.velocity-rpm

Category: Basic Configuration

- garrettmin

02 Sep 2024 19:43 - 02 Sep 2024 20:05

- Evgeny

- Evgeny

02 Sep 2024 18:57

Replied by Evgeny on topic Marco Reps video on youtube about EtherCAT

Marco Reps video on youtube about EtherCAT

Category: EtherCAT

- Project_Hopeless

02 Sep 2024 18:26

Replied by Project_Hopeless on topic Add Tab to Axis View Pane

Add Tab to Axis View Pane

Category: AXIS

- JackRay

- JackRay

02 Sep 2024 17:40

Replied by JackRay on topic 5 Axis configuration on linuxcnc

5 Axis configuration on linuxcnc

Category: Advanced Configuration

- bertoldo

- bertoldo

02 Sep 2024 16:51 - 02 Sep 2024 16:53

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- Aciera

02 Sep 2024 16:28 - 02 Sep 2024 16:30

Replied by Aciera on topic Modbus VFD startup delay?

Modbus VFD startup delay?

Category: Basic Configuration

- COFHAL

- COFHAL

02 Sep 2024 16:28

Replied by COFHAL on topic servo motor for a spindle

servo motor for a spindle

Category: Milling Machines

- COFHAL

- COFHAL

02 Sep 2024 16:15

Replied by COFHAL on topic Pendant with 7i73: question with analog inputs

Pendant with 7i73: question with analog inputs

Category: Driver Boards

- spumco

- spumco

02 Sep 2024 15:34

Replied by spumco on topic Modbus VFD startup delay?

Modbus VFD startup delay?

Category: Basic Configuration

Time to create page: 0.465 seconds