Search Results (Searched for: )

- paulsao

28 Aug 2024 14:14

- Masiwood123

28 Aug 2024 14:09 - 28 Aug 2024 19:31

Replied by Masiwood123 on topic Is there an easy way to swap axes?

Is there an easy way to swap axes?

Category: General LinuxCNC Questions

- AndyDM01

- AndyDM01

28 Aug 2024 13:32

- Todd Zuercher

28 Aug 2024 13:19

Replied by Todd Zuercher on topic Tool Height setter issue

Tool Height setter issue

Category: Advanced Configuration

- jjdege

28 Aug 2024 10:34

Replied by jjdege on topic Marco Reps video on youtube about EtherCAT

Marco Reps video on youtube about EtherCAT

Category: EtherCAT

- jimwhiting

- jimwhiting

28 Aug 2024 10:17

Replied by jimwhiting on topic Marco Reps video on youtube about EtherCAT

Marco Reps video on youtube about EtherCAT

Category: EtherCAT

- dabiaoge6699

- dabiaoge6699

- Mecanix

- Mecanix

28 Aug 2024 10:01 - 28 Aug 2024 10:08

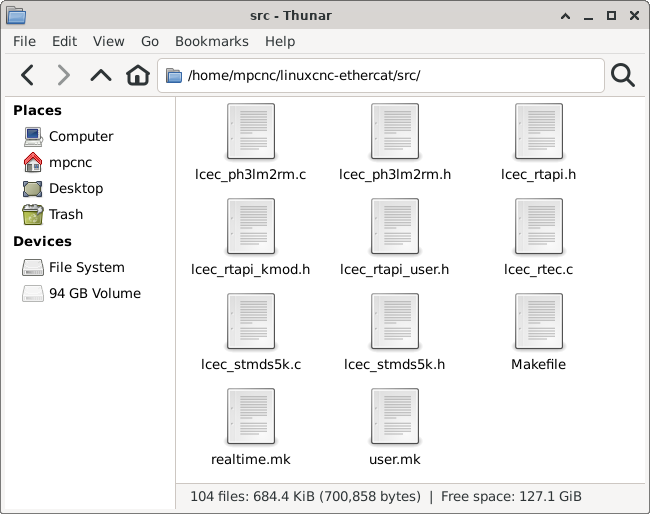

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Mecanix

- Mecanix

28 Aug 2024 09:47

Replied by Mecanix on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Moutomation

- Moutomation

28 Aug 2024 09:33

- Aciera

28 Aug 2024 09:11

- uugp

- uugp

28 Aug 2024 08:55

- Moutomation

- Moutomation

28 Aug 2024 07:56 - 28 Aug 2024 08:09

- rodw

28 Aug 2024 07:49

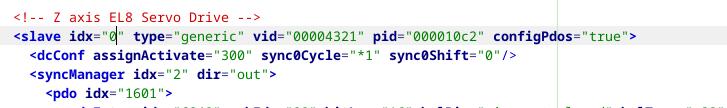

Replied by rodw on topic Amplifier Fault ECT60 Closed Loop

Amplifier Fault ECT60 Closed Loop

Category: EtherCAT

Time to create page: 1.235 seconds