Search Results (Searched for: )

- BaxEDM

17 Oct 2024 11:09 - 17 Oct 2024 11:09

- Kirvesmies

- Kirvesmies

17 Oct 2024 10:15

Replied by Kirvesmies on topic Getting started with 6i25+7i75+7i85s

Getting started with 6i25+7i75+7i85s

Category: PnCConf Wizard

- marq_torque

17 Oct 2024 09:40

Replied by marq_torque on topic linuxcnc-dev is missing?

linuxcnc-dev is missing?

Category: Installing LinuxCNC

- BaxEDM

17 Oct 2024 09:37

Replied by BaxEDM on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- burnie

- burnie

17 Oct 2024 09:28

Replied by burnie on topic Probe Basic machines won't update after modify in "Designer for PB"

Probe Basic machines won't update after modify in "Designer for PB"

Category: QtPyVCP

- my1987toyota

17 Oct 2024 09:13

- vasilyzel.

17 Oct 2024 08:30

Replied by vasilyzel. on topic Run/Step Hold/Resume Buttons

Run/Step Hold/Resume Buttons

Category: HAL Examples

- IronManDylan

- IronManDylan

17 Oct 2024 08:12

Fast Hole EDM from Hacked Parts was created by IronManDylan

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- vasilyzel.

17 Oct 2024 08:05

- Macwolf

- Macwolf

17 Oct 2024 08:04 - 17 Oct 2024 08:13

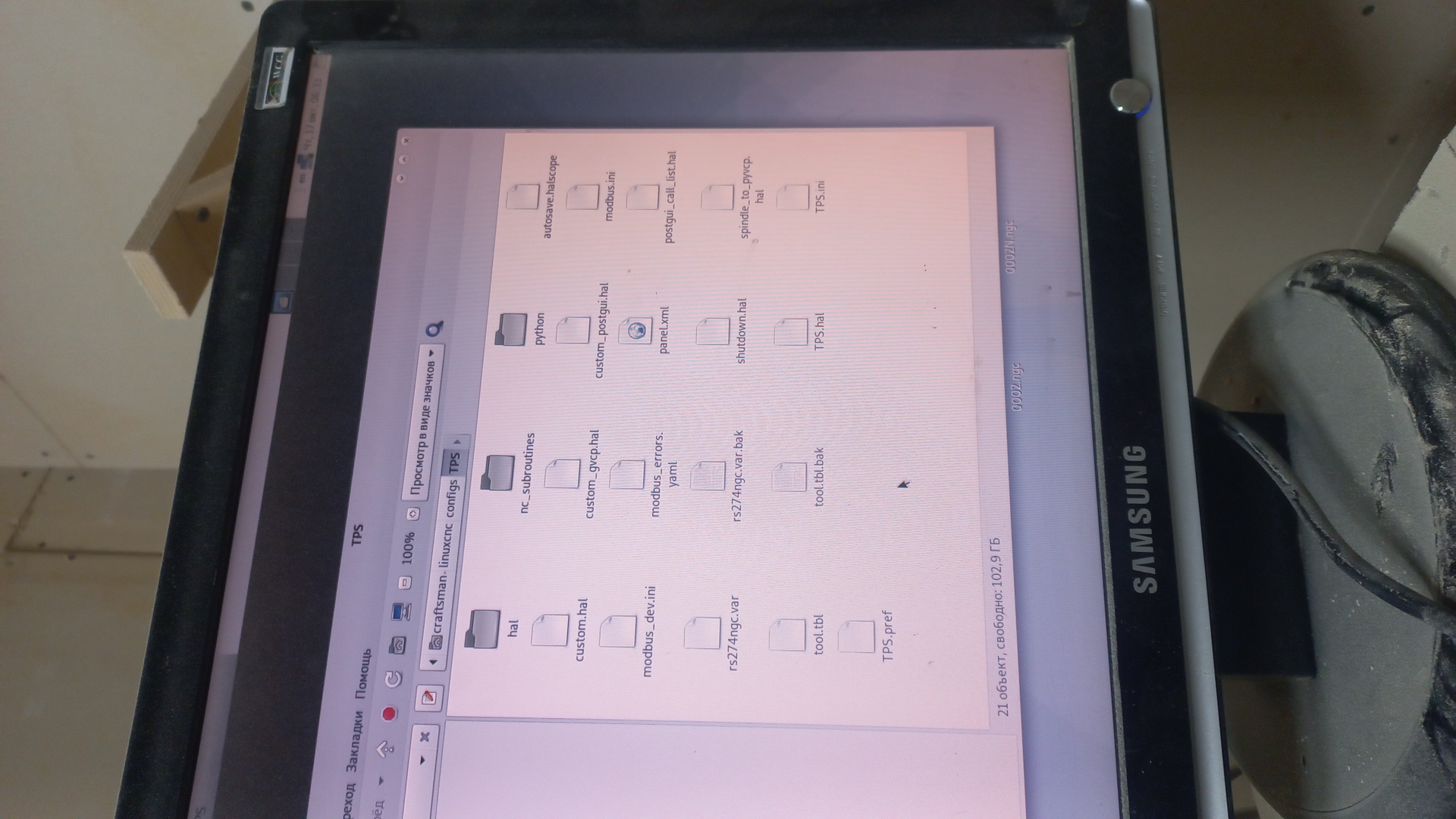

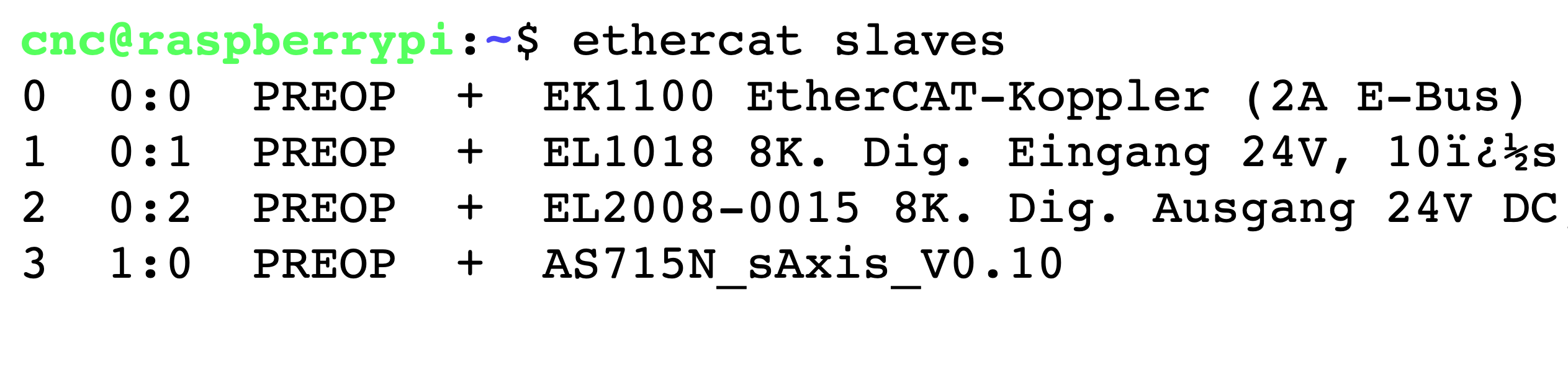

Replied by Macwolf on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- Aciera

17 Oct 2024 07:45

Replied by Aciera on topic Unterstützung bei der Automatisierung einer Simulation

Unterstützung bei der Automatisierung einer Simulation

Category: Deutsch

- jurod

17 Oct 2024 06:41

Replied by jurod on topic Remap 3D Cubic Spline Interpolation code by Python

Remap 3D Cubic Spline Interpolation code by Python

Category: O Codes (subroutines) and NGCGUI

- bkt

17 Oct 2024 06:32

- Vair8

- Vair8

17 Oct 2024 06:18

- Craigl

- Craigl

17 Oct 2024 05:55

Time to create page: 1.470 seconds