Search Results (Searched for: )

- Cant do this anymore bye all

06 Jun 2024 02:32

Replied by Cant do this anymore bye all on topic linuxcnc_2.9.1-amd64.hybrid.iso Intallation fail

linuxcnc_2.9.1-amd64.hybrid.iso Intallation fail

Category: Installing LinuxCNC

- cmorley

- cmorley

06 Jun 2024 02:04

- tommylight

06 Jun 2024 01:45

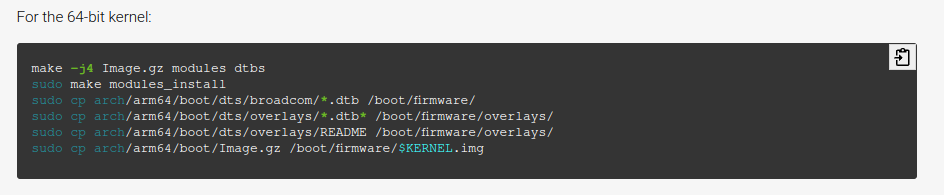

Replied by tommylight on topic Real Time Kernel

Real Time Kernel

Category: General LinuxCNC Questions

- phillc54

06 Jun 2024 00:00

- hmnijp

- hmnijp

05 Jun 2024 23:56

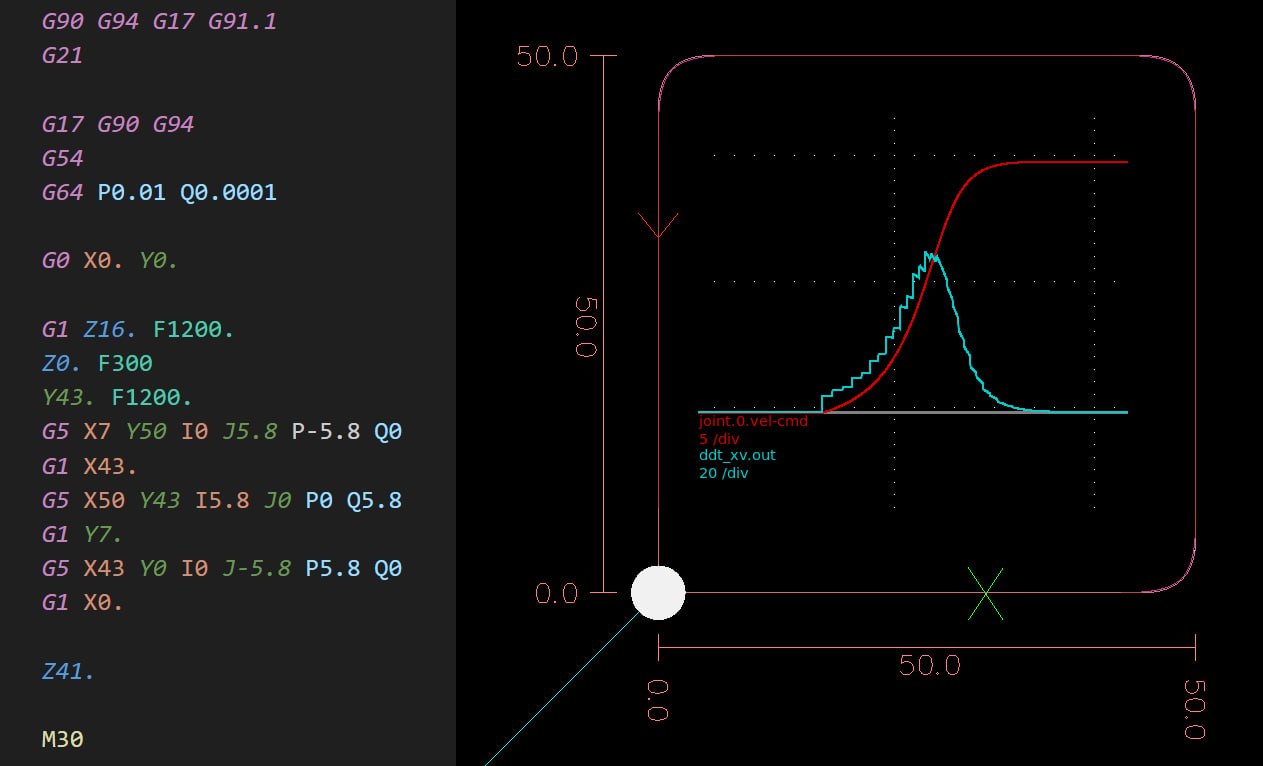

Replied by hmnijp on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- snowgoer540

05 Jun 2024 23:32 - 05 Jun 2024 23:39

Replied by snowgoer540 on topic Random Questions on setup

Random Questions on setup

Category: Plasmac

- andrew2085

- andrew2085

05 Jun 2024 22:06

Replied by andrew2085 on topic Real Time Kernel

Real Time Kernel

Category: General LinuxCNC Questions

- snowgoer540

05 Jun 2024 22:06 - 05 Jun 2024 22:09

Replied by snowgoer540 on topic Some inconveniences with using a touchscreen monitor

Some inconveniences with using a touchscreen monitor

Category: Plasmac

- eduard

05 Jun 2024 21:34

- dynodust

- dynodust

05 Jun 2024 21:14

- dynodust

- dynodust

05 Jun 2024 21:10

- zmrdko

05 Jun 2024 20:46

Replied by zmrdko on topic MS300 EtherCAT not going into OP state with CMM-02 (rev 131328)

MS300 EtherCAT not going into OP state with CMM-02 (rev 131328)

Category: EtherCAT

- royka

- royka

05 Jun 2024 20:44 - 05 Jun 2024 21:38

Replied by royka on topic Bad Latency Fujitsu Esprimo D756 i5 6500

Bad Latency Fujitsu Esprimo D756 i5 6500

Category: Computers and Hardware

- tommylight

05 Jun 2024 20:36

Replied by tommylight on topic Bad Latency Fujitsu Esprimo D756 i5 6500

Bad Latency Fujitsu Esprimo D756 i5 6500

Category: Computers and Hardware

- andrew2085

- andrew2085

05 Jun 2024 20:30

Replied by andrew2085 on topic Real Time Kernel

Real Time Kernel

Category: General LinuxCNC Questions

Time to create page: 0.624 seconds