Search Results (Searched for: )

- abdulasis12

- abdulasis12

09 Sep 2024 12:14

Replied by abdulasis12 on topic 7i77 TTL encoder

7i77 TTL encoder

Category: General LinuxCNC Questions

- rodw

09 Sep 2024 11:54

Replied by rodw on topic Where is qtplasmac_comp.hal loaded

Where is qtplasmac_comp.hal loaded

Category: Plasmac

- rodw

09 Sep 2024 11:51

Replied by rodw on topic Plasmac Breakaway roadblock (mental one anyway)

Plasmac Breakaway roadblock (mental one anyway)

Category: Plasmac

- rodw

09 Sep 2024 11:47

Replied by rodw on topic Showstopper Plasma Cutter retrofit

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

- rodw

09 Sep 2024 11:37

Replied by rodw on topic Showstopper Plasma Cutter retrofit

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

- bertoldo

- bertoldo

09 Sep 2024 11:19

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- rodw

09 Sep 2024 11:17 - 09 Sep 2024 11:22

Replied by rodw on topic Showstopper Plasma Cutter retrofit

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

- my1987toyota

09 Sep 2024 11:16

Replied by my1987toyota on topic What Factors to Consider When Choosing a Pick and Place Machine?

What Factors to Consider When Choosing a Pick and Place Machine?

Category: Pick and Place

- rodw

09 Sep 2024 10:56

Replied by rodw on topic Showstopper Plasma Cutter retrofit

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

- mBender

- mBender

09 Sep 2024 10:52

Replied by mBender on topic Linuxcnc start disables Parallel port of PCI Express card

Linuxcnc start disables Parallel port of PCI Express card

Category: Basic Configuration

- meister

- meister

09 Sep 2024 10:48

Replied by meister on topic Custom DH Parameters Kinematics

Custom DH Parameters Kinematics

Category: Advanced Configuration

- rodw

09 Sep 2024 10:41

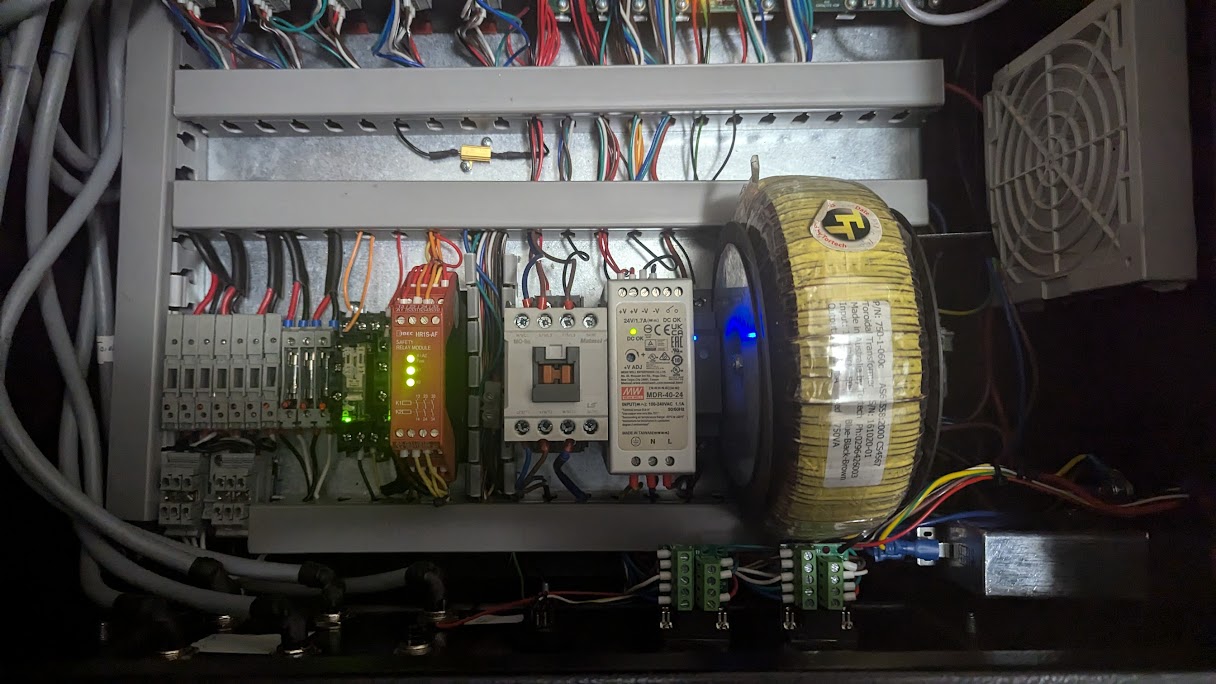

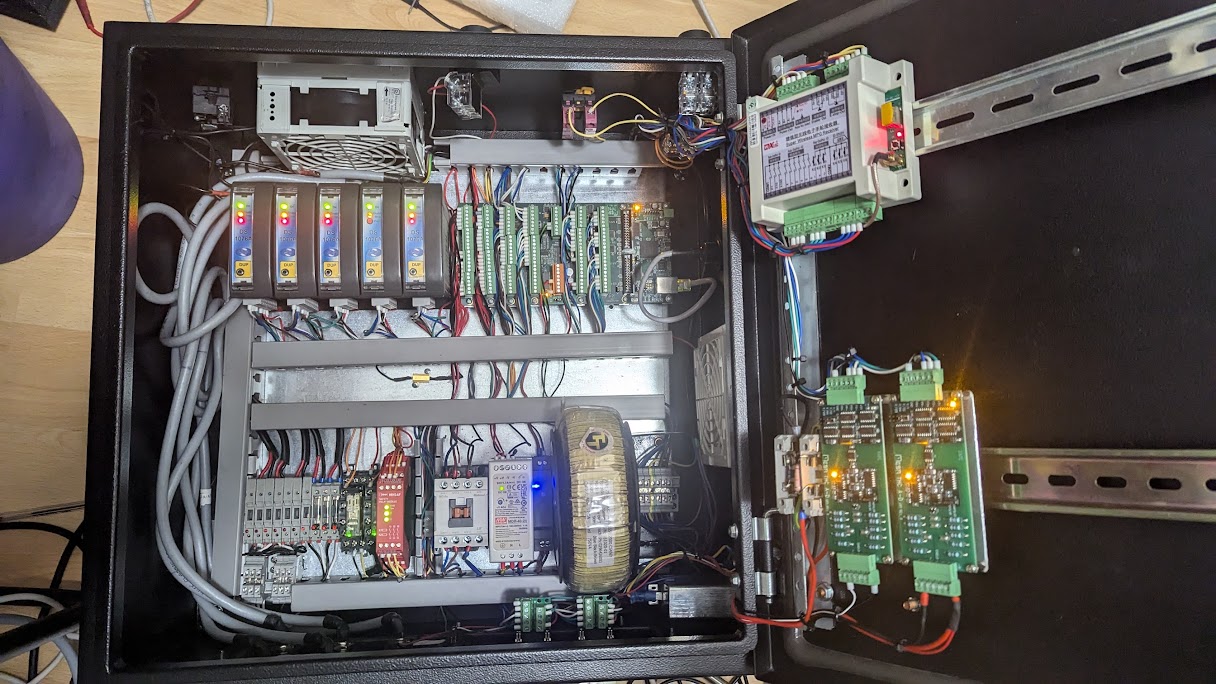

Showstopper Plasma Cutter retrofit was created by rodw

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

- Abdulkareem

- Abdulkareem

09 Sep 2024 10:36

Replied by Abdulkareem on topic Custom DH Parameters Kinematics

Custom DH Parameters Kinematics

Category: Advanced Configuration

- Abdulkareem

- Abdulkareem

09 Sep 2024 10:35

Replied by Abdulkareem on topic Custom DH Parameters Kinematics

Custom DH Parameters Kinematics

Category: Advanced Configuration

- meister

- meister

09 Sep 2024 10:24

Replied by meister on topic Custom DH Parameters Kinematics

Custom DH Parameters Kinematics

Category: Advanced Configuration

Time to create page: 0.698 seconds