Search Results (Searched for: )

- Hakan

- Hakan

16 May 2025 14:59

- langdons

- langdons

16 May 2025 14:52 - 16 May 2025 16:03

Replied by langdons on topic Actual position and Commanded position differ, using cia402 [SOLVED]

Actual position and Commanded position differ, using cia402 [SOLVED]

Category: Basic Configuration

- PCW

16 May 2025 14:51

- jochen91

- jochen91

16 May 2025 14:50

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Category: Advanced Configuration

- langdons

- langdons

16 May 2025 14:50

Replied by langdons on topic Ohmic probe aborts immediately

Ohmic probe aborts immediately

Category: Plasmac

- langdons

- langdons

16 May 2025 14:48 - 16 May 2025 16:02

Replied by langdons on topic Actual position and Commanded position differ, using cia402 [SOLVED]

Actual position and Commanded position differ, using cia402 [SOLVED]

Category: Basic Configuration

- langdons

- langdons

16 May 2025 14:41

Replied by langdons on topic [SOLVED] New wifi card causes second parallel port to stop working

[SOLVED] New wifi card causes second parallel port to stop working

Category: General LinuxCNC Questions

- Muftijaja

- Muftijaja

16 May 2025 14:29 - 16 May 2025 14:33

- PCW

16 May 2025 14:29

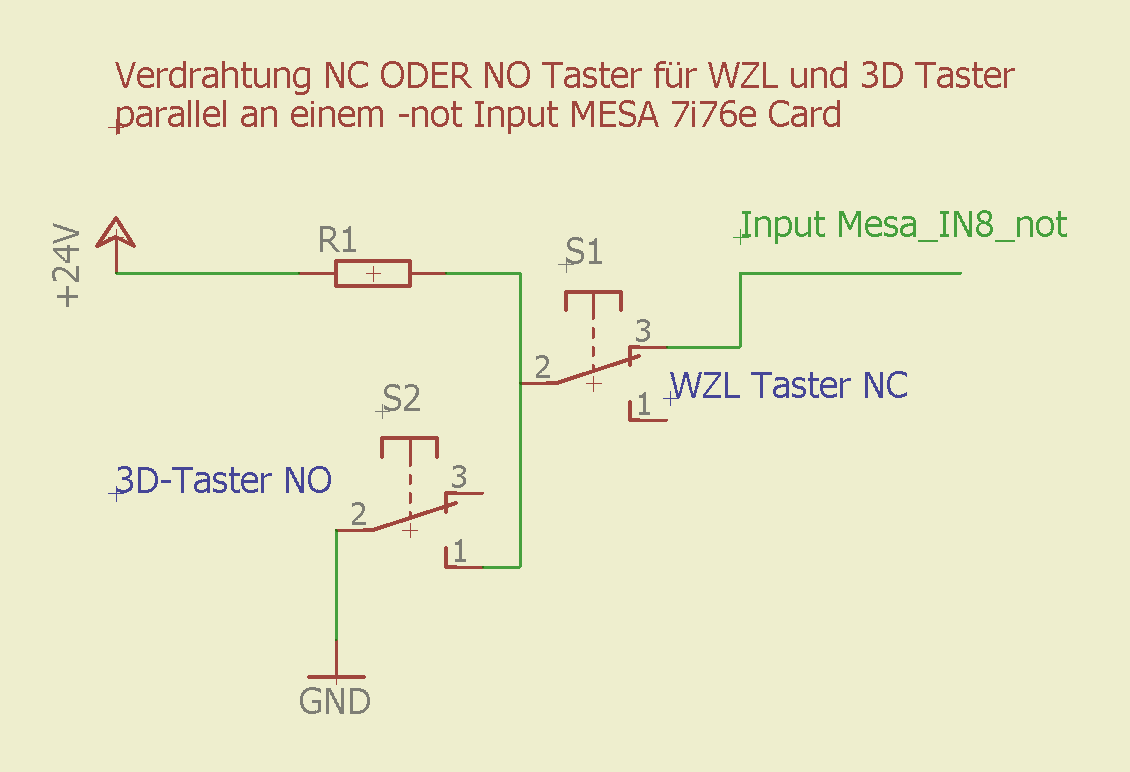

Replied by PCW on topic MESA 7i76E burning out issue

MESA 7i76E burning out issue

Category: Driver Boards

- cmorley

- cmorley

16 May 2025 14:26

- knipknap

- knipknap

16 May 2025 14:19 - 16 May 2025 14:24

MESA 7i76E burning out issue was created by knipknap

MESA 7i76E burning out issue

Category: Driver Boards

- sajurcaju

- sajurcaju

16 May 2025 13:43

Replied by sajurcaju on topic [SOLVED] New wifi card causes second parallel port to stop working

[SOLVED] New wifi card causes second parallel port to stop working

Category: General LinuxCNC Questions

- cmorley

- cmorley

16 May 2025 13:14

- tommylight

16 May 2025 13:04

Replied by tommylight on topic Issues installing LinuxCNC

Issues installing LinuxCNC

Category: Installing LinuxCNC

- unknown

- unknown

16 May 2025 12:46

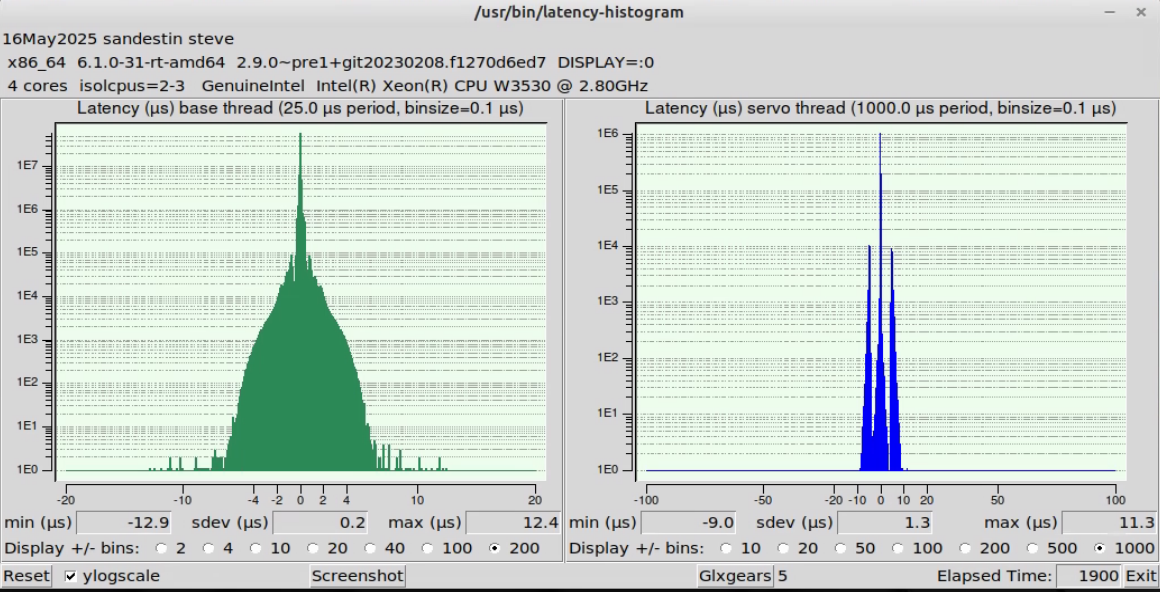

Replied by unknown on topic Need guidence to improve latency and speed

Need guidence to improve latency and speed

Category: Basic Configuration

Time to create page: 0.400 seconds