Search Results (Searched for: )

- Rune_cnc

- Rune_cnc

29 Apr 2025 12:10

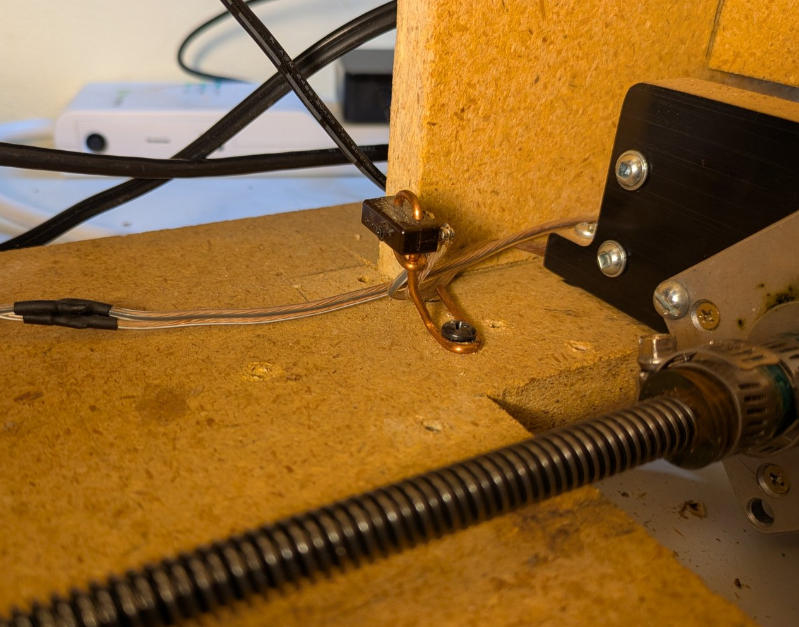

Using npn Inductive sensor for end stop. was created by Rune_cnc

Using npn Inductive sensor for end stop.

Category: Basic Configuration

- pgf

- pgf

29 Apr 2025 11:57

"From scraps were ye made, and scraps ye shall be!" was created by pgf

"From scraps were ye made, and scraps ye shall be!"

Category: Show Your Stuff

- Spyderbreath

29 Apr 2025 11:03

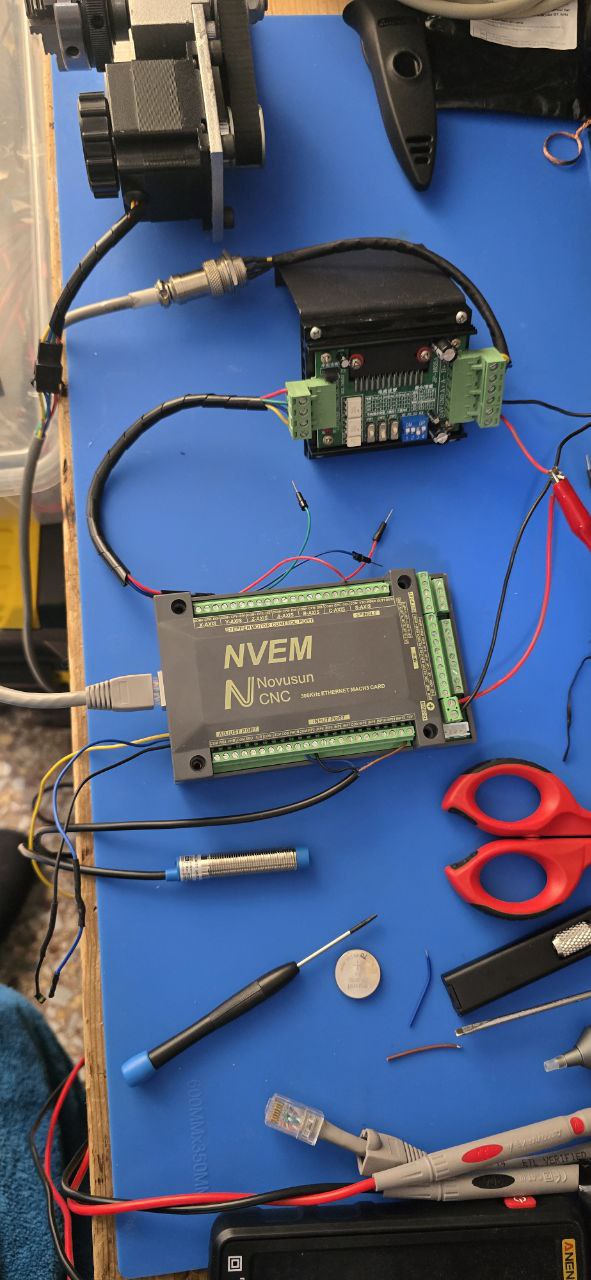

Replied by Spyderbreath on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Muftijaja

- Muftijaja

29 Apr 2025 11:02 - 29 Apr 2025 12:11

Replied by Muftijaja on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- Muftijaja

- Muftijaja

29 Apr 2025 10:40 - 29 Apr 2025 10:42

Replied by Muftijaja on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- zmrdko

29 Apr 2025 10:24

Replied by zmrdko on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- DarkPhoinix

- DarkPhoinix

29 Apr 2025 10:23

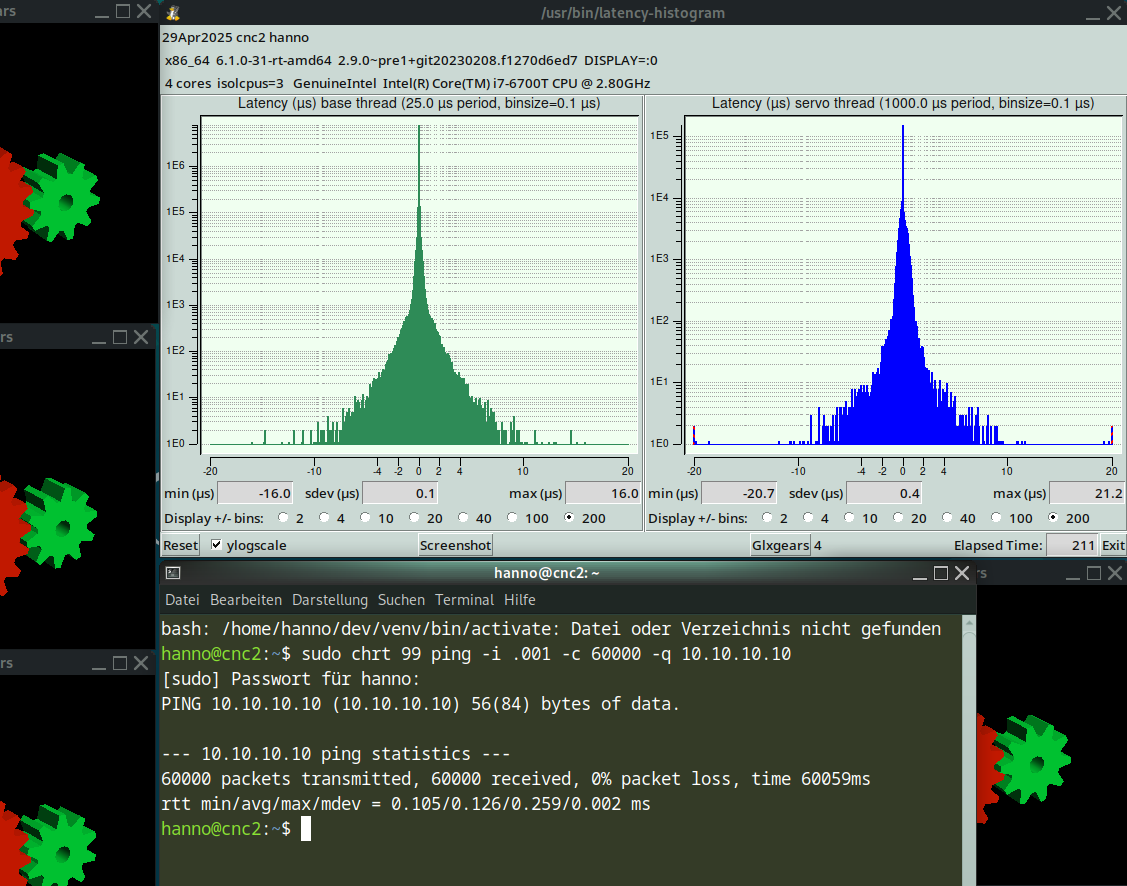

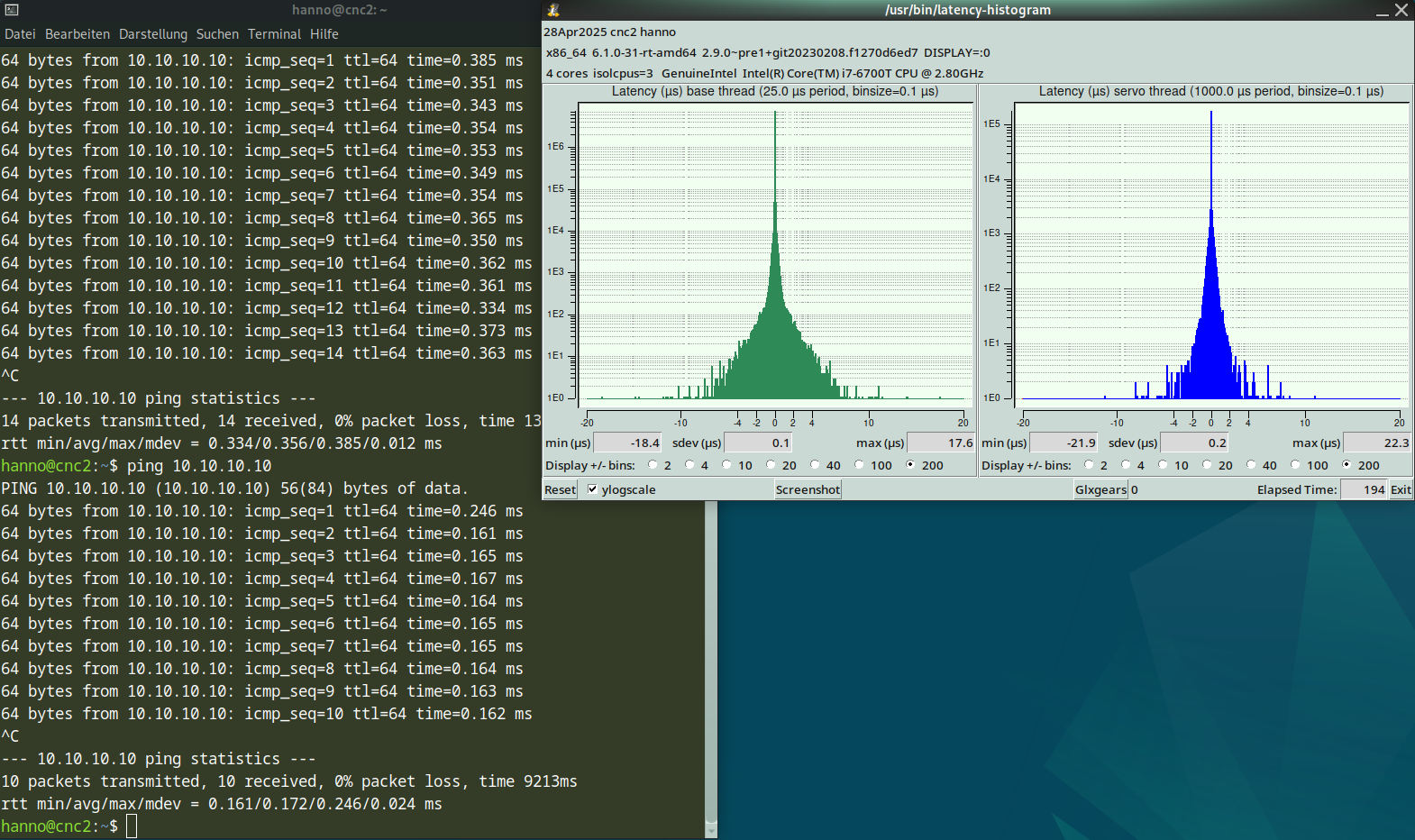

Replied by DarkPhoinix on topic [SOLVED]linuxcnc Latency test ambiguous results

[SOLVED]linuxcnc Latency test ambiguous results

Category: General LinuxCNC Questions

- emresensoy

- emresensoy

29 Apr 2025 09:22

Replied by emresensoy on topic QtPyVCP designer plugin fails

QtPyVCP designer plugin fails

Category: QtPyVCP

- Surmetall

29 Apr 2025 09:19

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Category: Turning

- rodw

29 Apr 2025 09:11

Replied by rodw on topic Tandem Y Axis in stepconf assistance.

Tandem Y Axis in stepconf assistance.

Category: StepConf Wizard

- stenly

- stenly

29 Apr 2025 09:09

Replied by stenly on topic Implementing Spindle Homing for DELTA C2000 Plus (In)correctly?

Implementing Spindle Homing for DELTA C2000 Plus (In)correctly?

Category: EtherCAT

- Neiji_msk

- Neiji_msk

29 Apr 2025 08:36

Replied by Neiji_msk on topic EtherCAT and selfmade driver

EtherCAT and selfmade driver

Category: EtherCAT

- Hakan

- Hakan

29 Apr 2025 08:34

Replied by Hakan on topic First time to try build my xml for not listed ethercat in-out component

First time to try build my xml for not listed ethercat in-out component

Category: EtherCAT

- dannym

- dannym

29 Apr 2025 08:15

Replied by dannym on topic Z axis is being controlled by A

Z axis is being controlled by A

Category: Basic Configuration

- Hakan

- Hakan

29 Apr 2025 07:47

Replied by Hakan on topic General Questions about using ethercat

General Questions about using ethercat

Category: EtherCAT

Time to create page: 0.392 seconds