Search Results (Searched for: )

- Sternfox

- Sternfox

04 Mar 2025 16:42 - 04 Mar 2025 16:48

Replied by Sternfox on topic Spindle orientation

Spindle orientation

Category: Advanced Configuration

- 109jb

- 109jb

04 Mar 2025 16:32

Lathe spindle index only? was created by 109jb

Lathe spindle index only?

Category: Basic Configuration

- andypugh

04 Mar 2025 16:23

Replied by andypugh on topic Calling pockets with carousel

Calling pockets with carousel

Category: Basic Configuration

- andypugh

04 Mar 2025 16:18

Replied by andypugh on topic How to access rt pins in user space

How to access rt pins in user space

Category: General LinuxCNC Questions

- Wischi

- Wischi

04 Mar 2025 16:18

Replied by Wischi on topic Question: Gmoccapy 3.4.2 and touchscreen

Question: Gmoccapy 3.4.2 and touchscreen

Category: Gmoccapy

- andypugh

04 Mar 2025 16:13

Replied by andypugh on topic Spindle orientation

Spindle orientation

Category: Advanced Configuration

- andypugh

04 Mar 2025 16:11

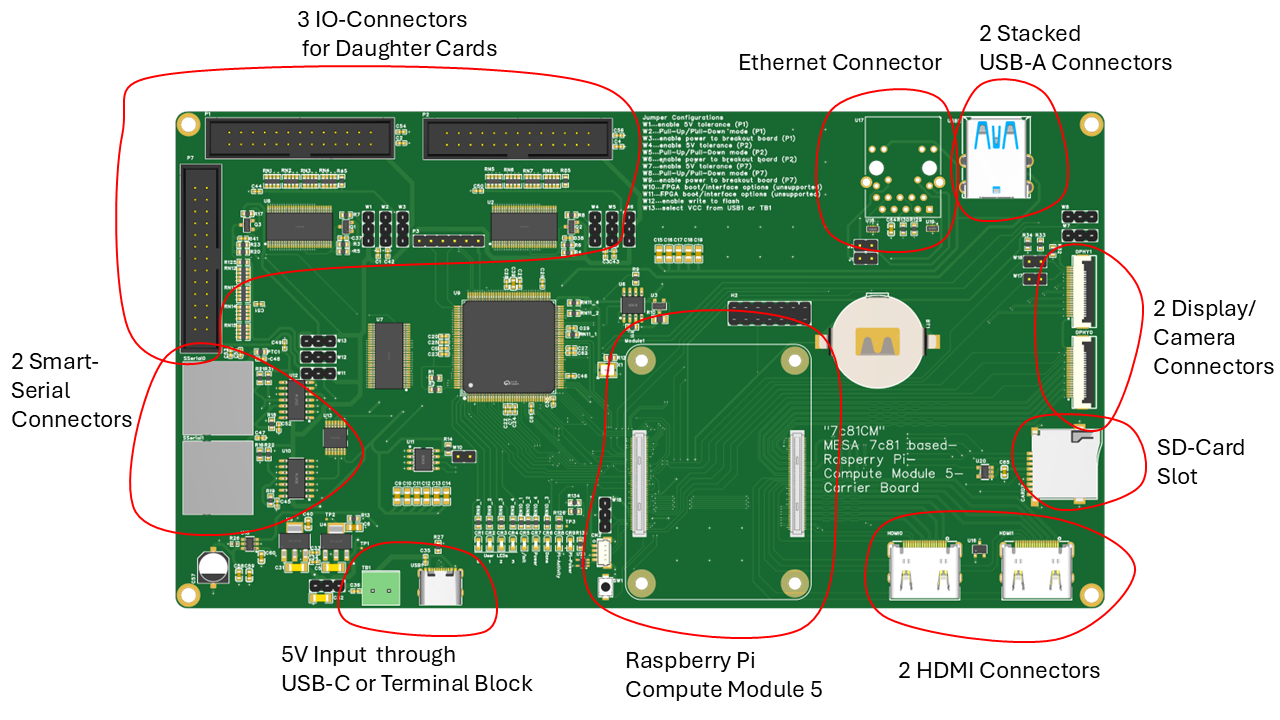

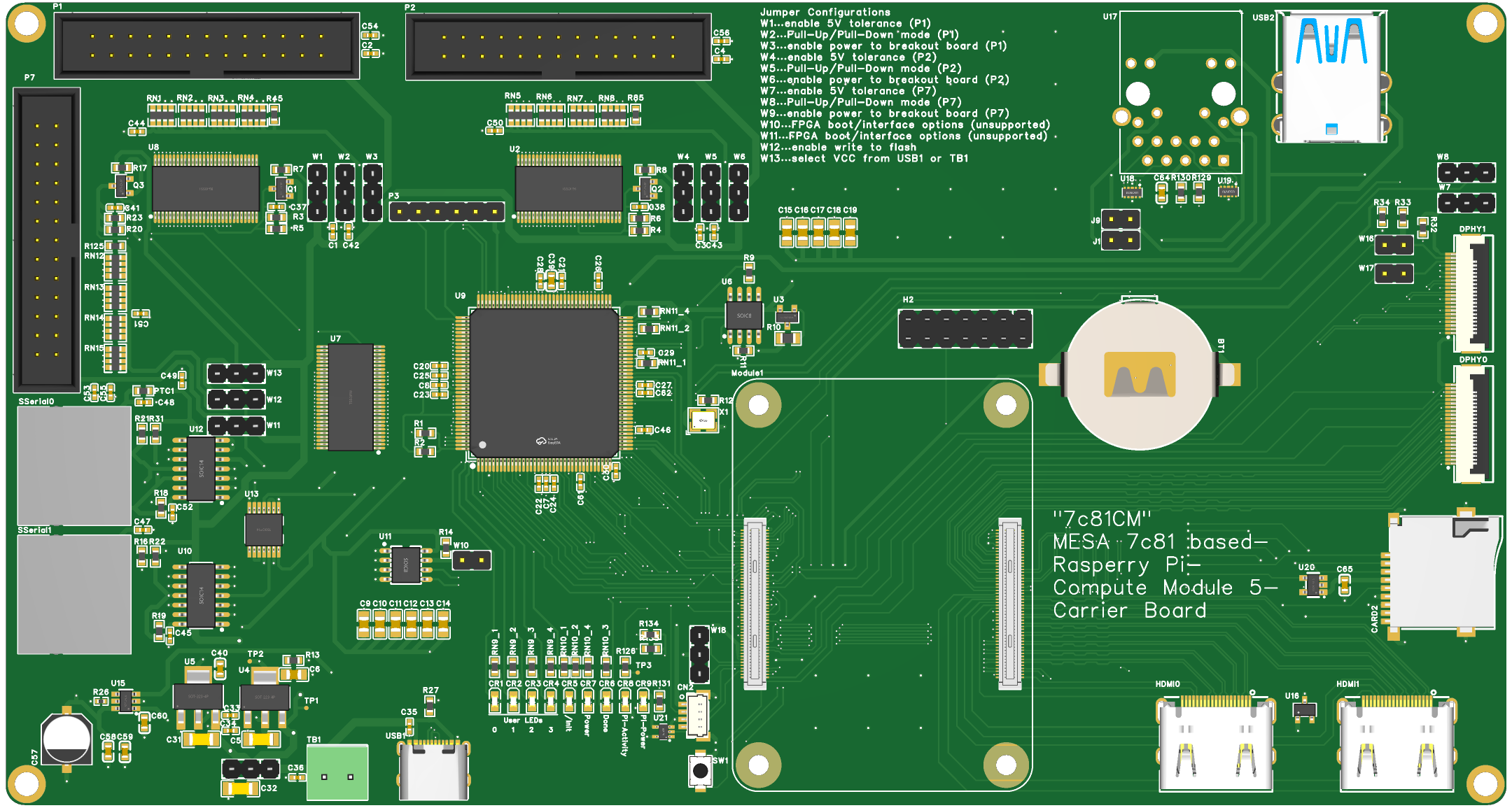

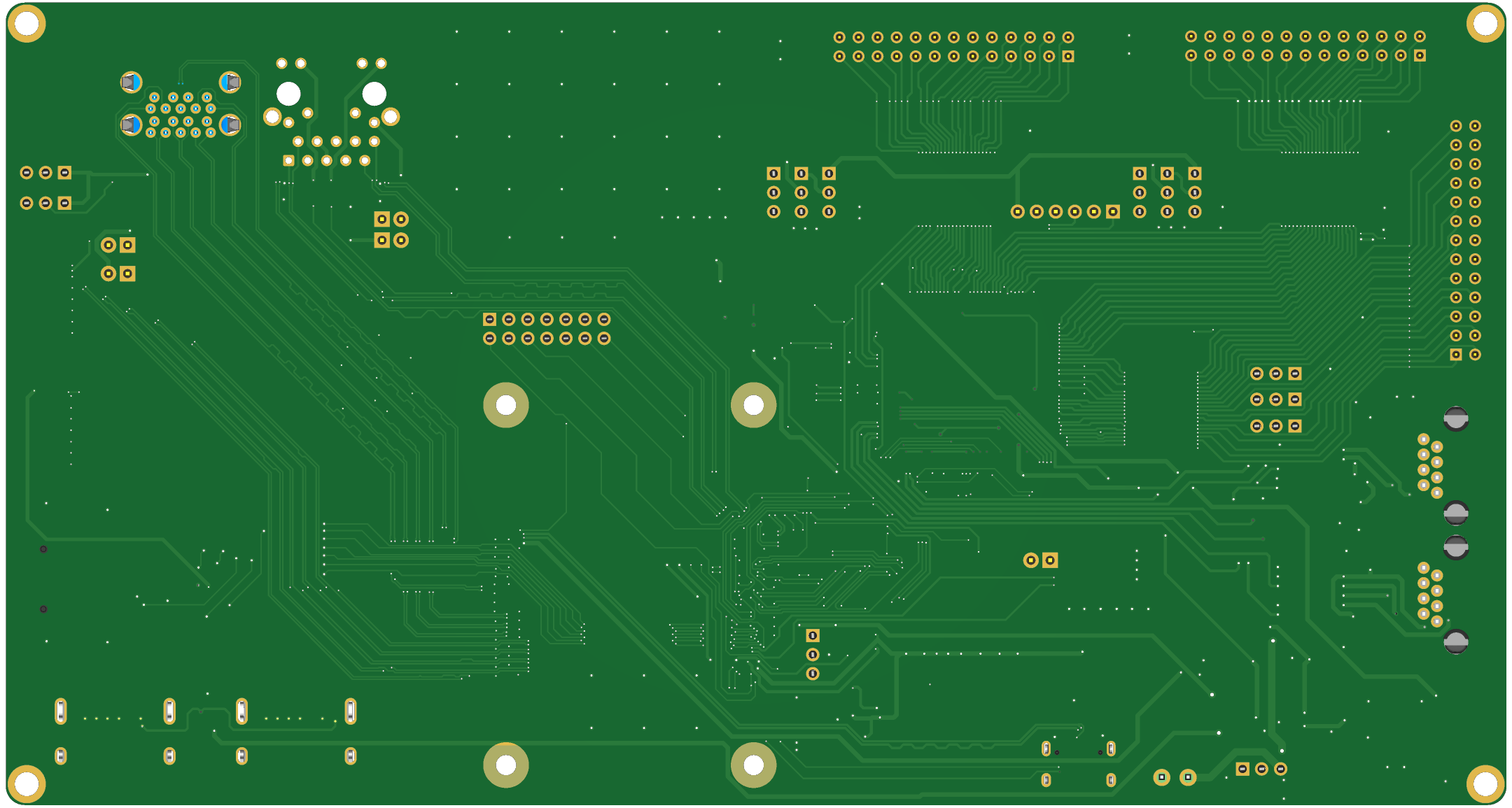

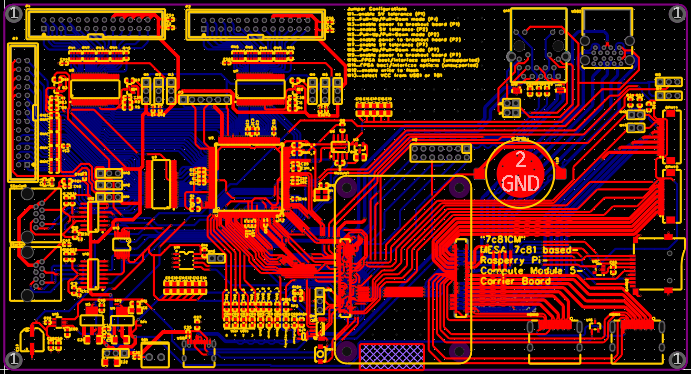

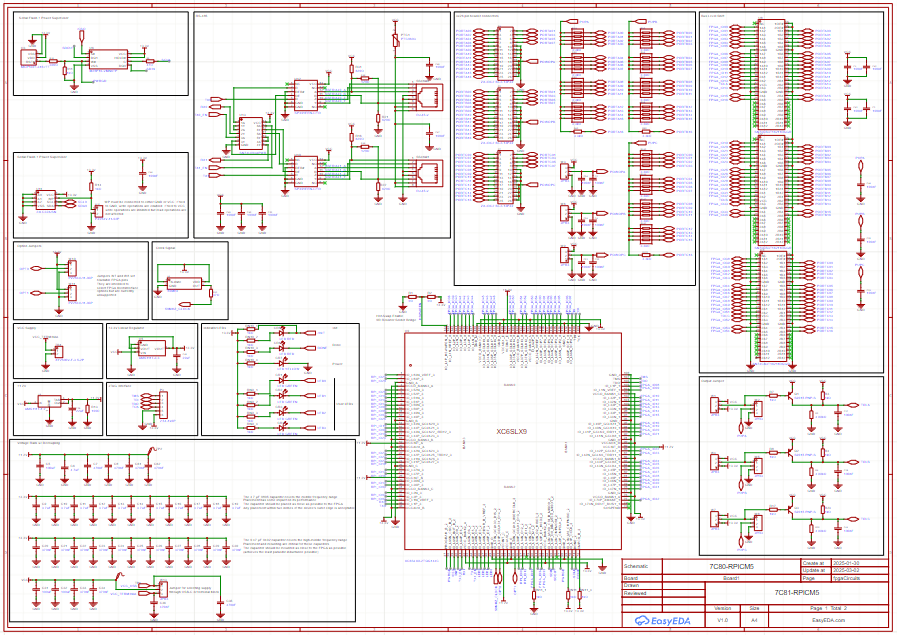

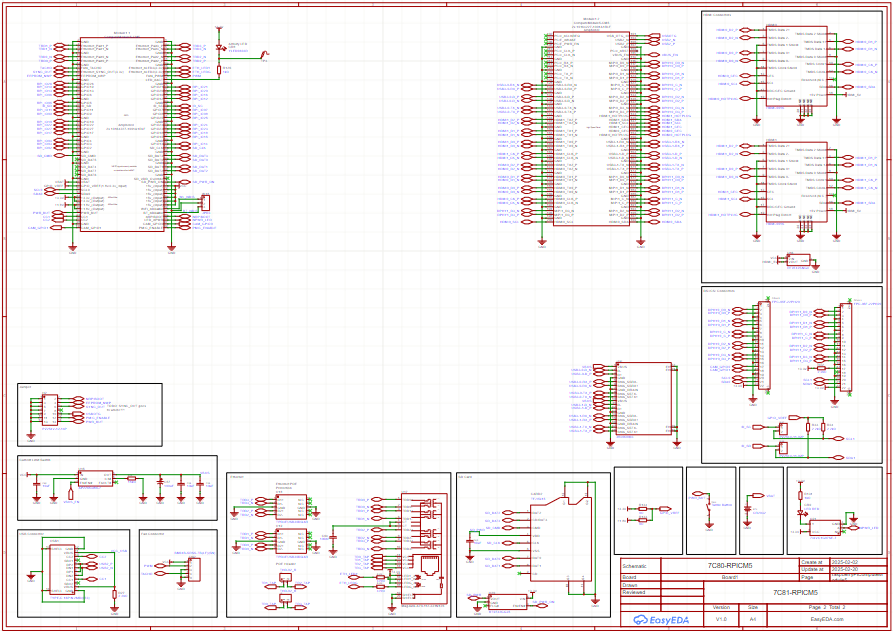

Replied by andypugh on topic Custom "MESA 7c81 Clone" PCB featuring a Raspberry Pi Compute Module 5

Custom "MESA 7c81 Clone" PCB featuring a Raspberry Pi Compute Module 5

Category: Driver Boards

- andypugh

04 Mar 2025 16:07

Replied by andypugh on topic Path to source code LCNC

Path to source code LCNC

Category: General LinuxCNC Questions

- Niklas

- Niklas

04 Mar 2025 16:03

- andypugh

04 Mar 2025 16:02

Replied by andypugh on topic CamBam 3D profile 2-way passes?

CamBam 3D profile 2-way passes?

Category: Post Processors

- andypugh

04 Mar 2025 16:01

Replied by andypugh on topic Fix for "Go Home" button qtdragon_hd (make it go to the Z value you need)

Fix for "Go Home" button qtdragon_hd (make it go to the Z value you need)

Category: Qtvcp

- andypugh

04 Mar 2025 15:55

Replied by andypugh on topic TAMAGAWA encoders model TS5661N132

TAMAGAWA encoders model TS5661N132

Category: General LinuxCNC Questions

- hans48

- hans48

04 Mar 2025 15:36

- COFHAL

- COFHAL

04 Mar 2025 15:34

TAMAGAWA encoders model TS5661N132 was created by COFHAL

TAMAGAWA encoders model TS5661N132

Category: General LinuxCNC Questions

- hakinen2255

- hakinen2255

04 Mar 2025 14:45

Replied by hakinen2255 on topic How to open QT ui file in LinuxCNC

How to open QT ui file in LinuxCNC

Category: Qtvcp

Time to create page: 0.418 seconds