Search Results (Searched for: )

- Surmetall

08 Mar 2025 11:45

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Category: Turning

- Surmetall

08 Mar 2025 11:33 - 08 Mar 2025 11:36

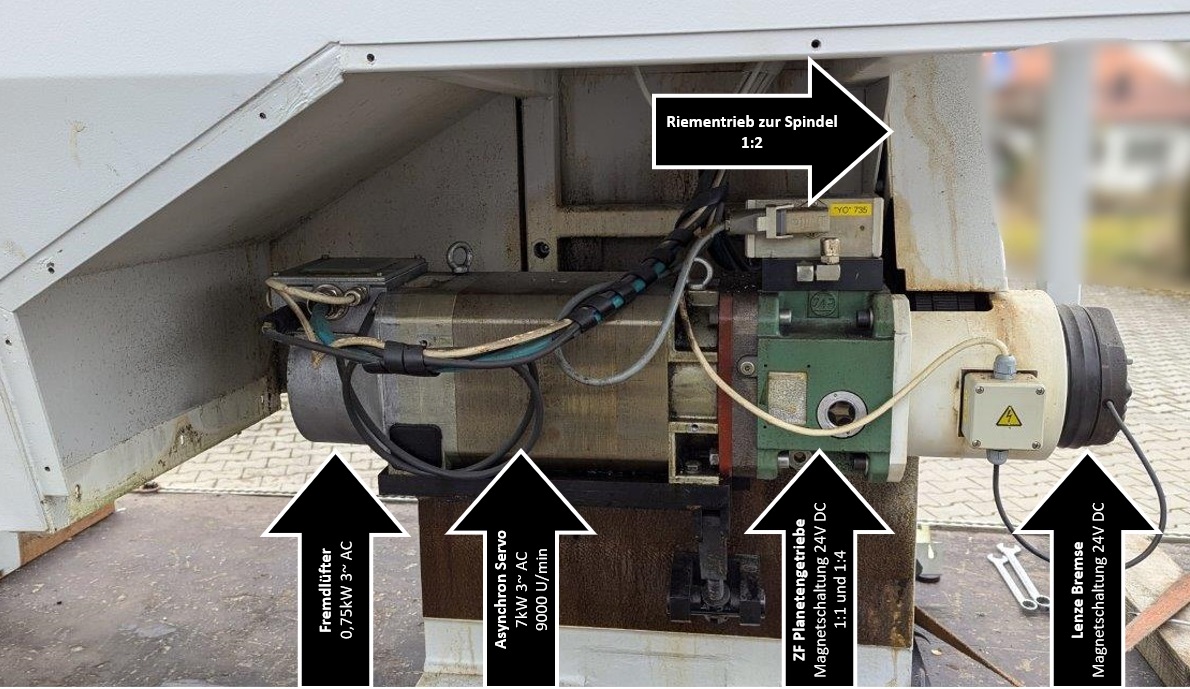

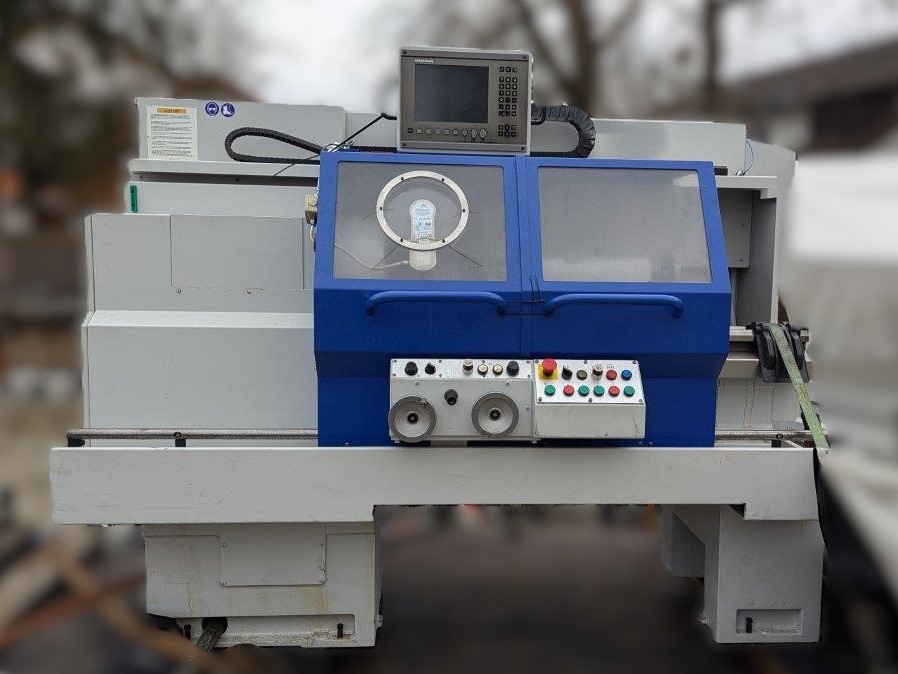

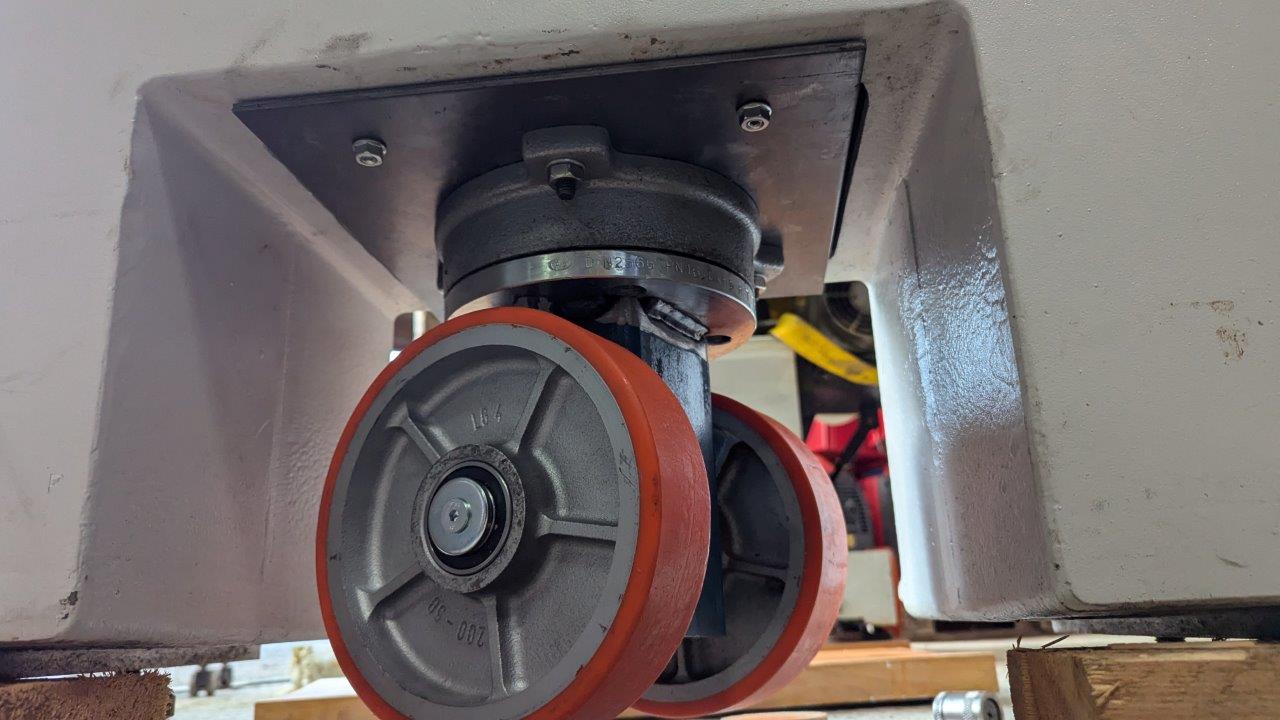

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT? was created by Surmetall

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Category: Turning

- MillingMarvin

- MillingMarvin

08 Mar 2025 11:12 - 08 Mar 2025 12:48

Rigid Tapping - VFD and needed encoder ppm was created by MillingMarvin

Rigid Tapping - VFD and needed encoder ppm

Category: Milling Machines

- zz912

08 Mar 2025 10:14 - 08 Mar 2025 10:42

Replied by zz912 on topic Path to source code LCNC

Path to source code LCNC

Category: General LinuxCNC Questions

- Surmetall

08 Mar 2025 09:25

problem to start a new topic was created by Surmetall

problem to start a new topic

Category: Forum Questions

- abdulasis12

- abdulasis12

08 Mar 2025 09:13

Replied by abdulasis12 on topic Machine Jerk When Post process all command CAM

Machine Jerk When Post process all command CAM

Category: General LinuxCNC Questions

- StoneB

- StoneB

08 Mar 2025 09:10 - 09 Mar 2025 20:56

Raspi 5 touchscreen experience - recommendation was created by StoneB

Raspi 5 touchscreen experience - recommendation

Category: Computers and Hardware

- timo

- timo

08 Mar 2025 08:25 - 08 Mar 2025 08:30

Replied by timo on topic Lathe spindle index only?

Lathe spindle index only?

Category: Basic Configuration

- abdulasis12

- abdulasis12

08 Mar 2025 08:15

Machine Jerk When Post process all command CAM was created by abdulasis12

Machine Jerk When Post process all command CAM

Category: General LinuxCNC Questions

Time to create page: 0.578 seconds