Search Results (Searched for: )

- Aciera

14 Aug 2024 11:27 - 14 Aug 2024 12:17

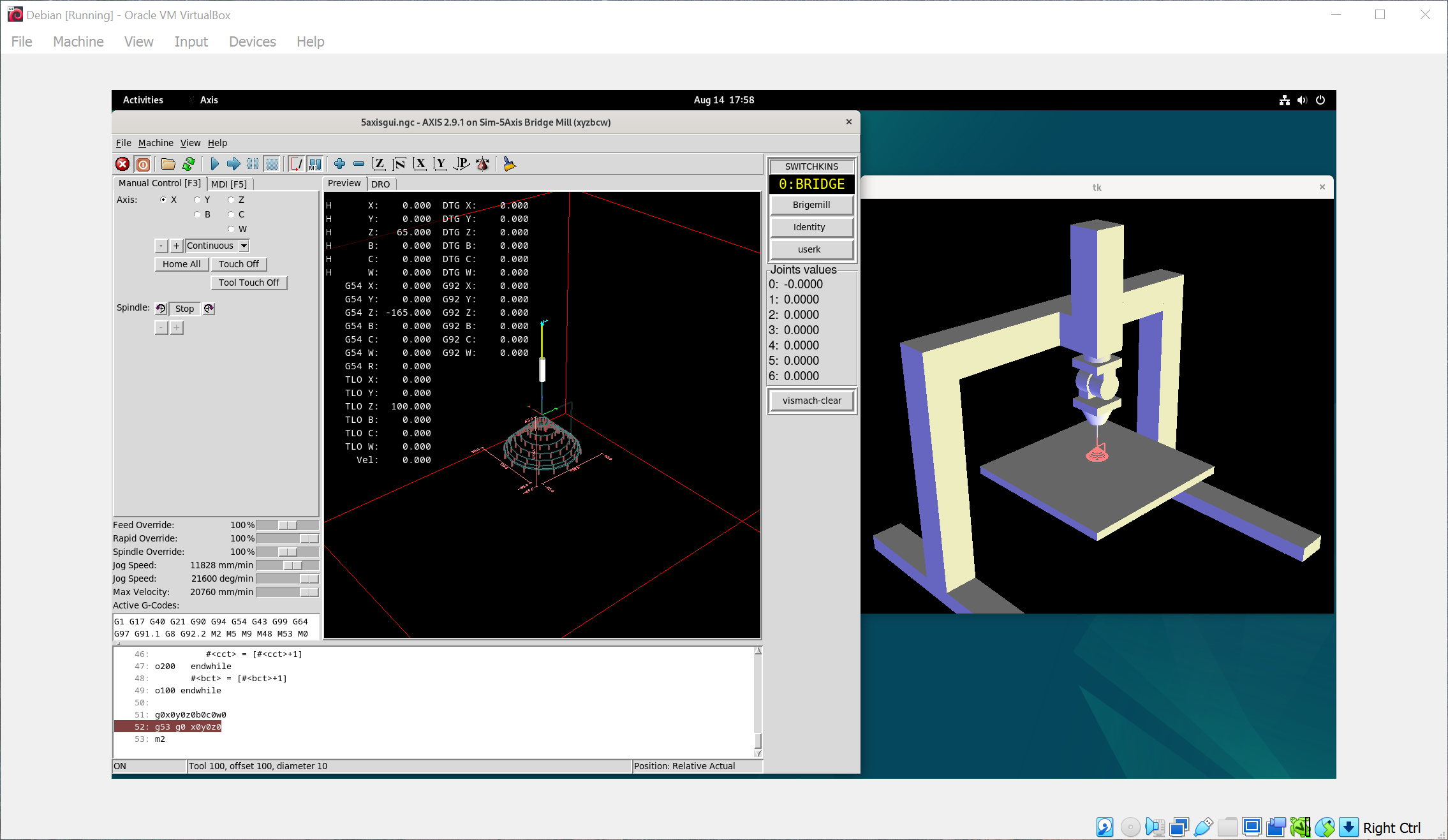

Replied by Aciera on topic How to add user kinematics for 5 axis bridge mill?

How to add user kinematics for 5 axis bridge mill?

Category: General LinuxCNC Questions

- winyk

- winyk

14 Aug 2024 11:01

How to add user kinematics for 5 axis bridge mill? was created by winyk

How to add user kinematics for 5 axis bridge mill?

Category: General LinuxCNC Questions

- nmsk

14 Aug 2024 10:06 - 15 Aug 2024 11:24

Can't set it to OP when configPdos is true was created by nmsk

Can't set it to OP when configPdos is true

Category: EtherCAT

- winyk

- winyk

14 Aug 2024 10:03

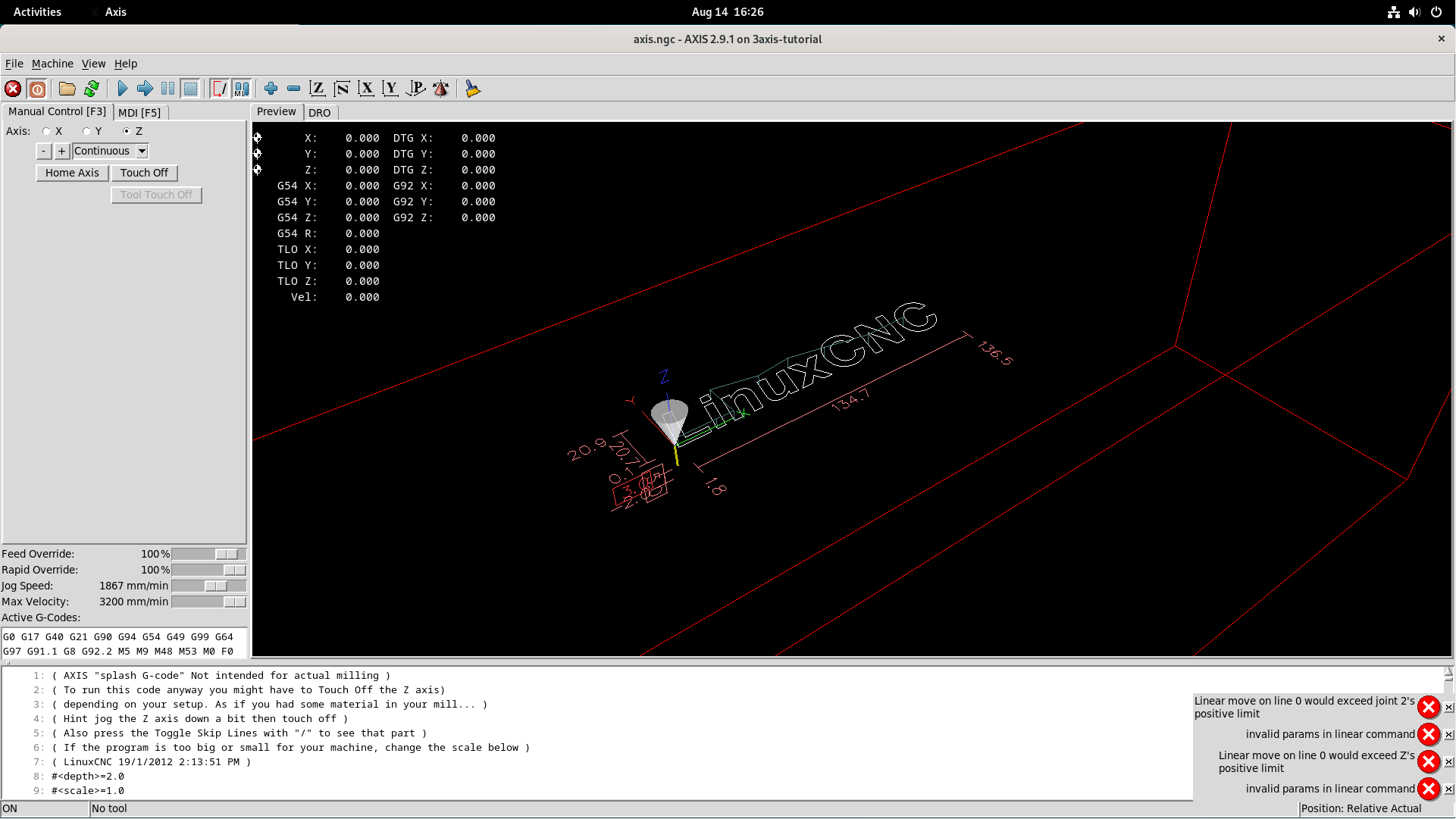

Replied by winyk on topic How can I modify trivkins.c? (and also other kinematics files)

How can I modify trivkins.c? (and also other kinematics files)

Category: General LinuxCNC Questions

- anfänger

14 Aug 2024 08:33

Replied by anfänger on topic Py3 - Probe Basic Config Conversion Doc Lcnc 2.9+

Py3 - Probe Basic Config Conversion Doc Lcnc 2.9+

Category: QtPyVCP

- Limo

- Limo

14 Aug 2024 08:32

- arijitdutta

- arijitdutta

14 Aug 2024 05:44 - 14 Aug 2024 05:45

Replied by arijitdutta on topic PnCConf USB Jogging Problem

PnCConf USB Jogging Problem

Category: PnCConf Wizard

- Mecanix

- Mecanix

14 Aug 2024 05:29

Replied by Mecanix on topic Data transfer LinuxCNC to / from custom board - Solved

Data transfer LinuxCNC to / from custom board - Solved

Category: Advanced Configuration

- Cant do this anymore bye all

14 Aug 2024 04:54

Replied by Cant do this anymore bye all on topic Data transfer LinuxCNC to / from custom board - Solved

Data transfer LinuxCNC to / from custom board - Solved

Category: Advanced Configuration

- Benb

14 Aug 2024 01:50

- PCW

14 Aug 2024 01:17

Replied by PCW on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- Mecanix

- Mecanix

14 Aug 2024 00:43

Replied by Mecanix on topic Data transfer LinuxCNC to / from custom board - Solved

Data transfer LinuxCNC to / from custom board - Solved

Category: Advanced Configuration

- tommylight

14 Aug 2024 00:41

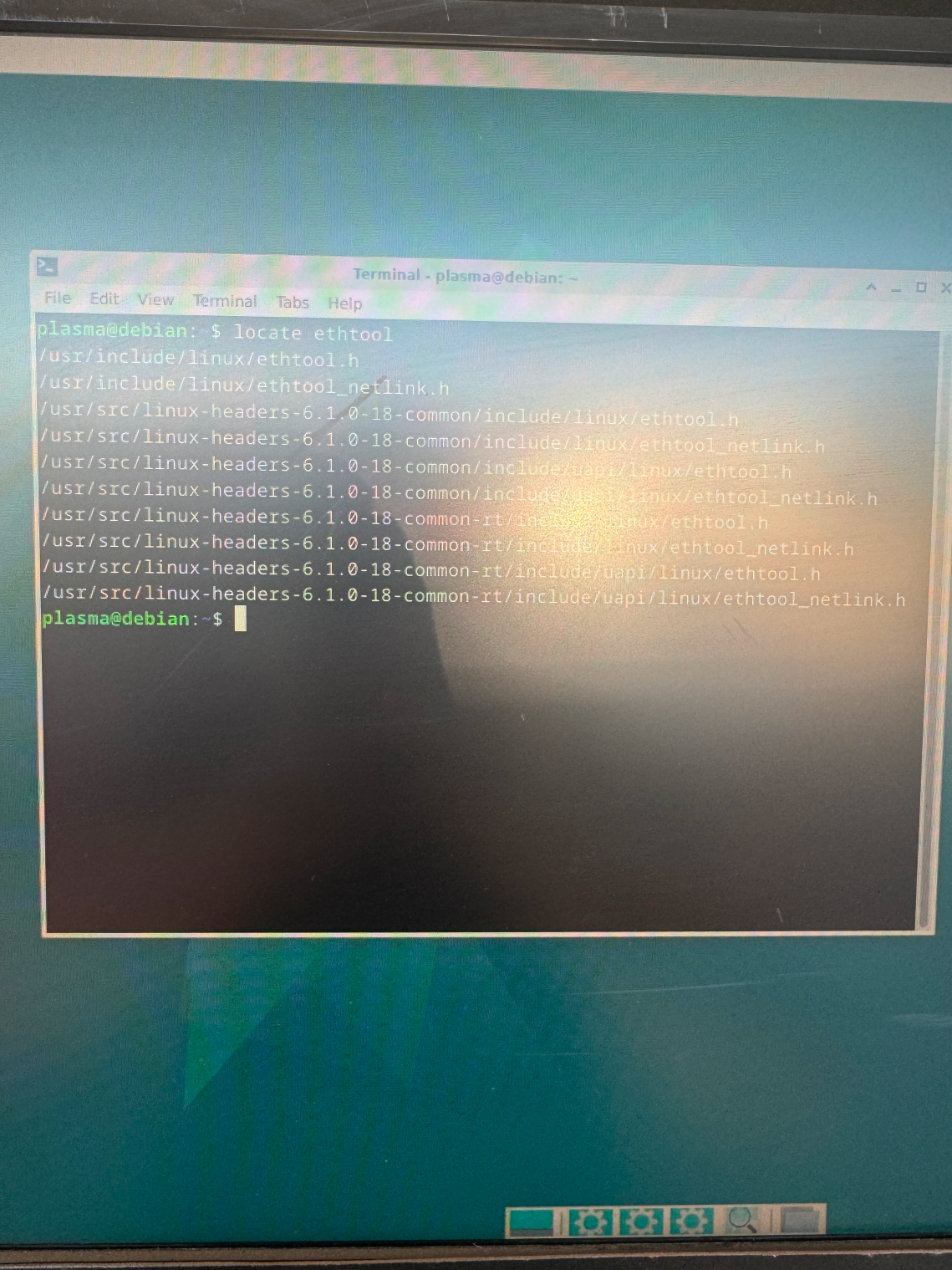

Replied by tommylight on topic help with installation

help with installation

Category: Installing LinuxCNC

- Cant do this anymore bye all

14 Aug 2024 00:17

Replied by Cant do this anymore bye all on topic Data transfer LinuxCNC to / from custom board - Solved

Data transfer LinuxCNC to / from custom board - Solved

Category: Advanced Configuration

- RMJ fabrication

- RMJ fabrication

14 Aug 2024 00:16

Replied by RMJ fabrication on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

Time to create page: 0.469 seconds