Bob's Plasmac Build

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

03 Sep 2019 00:04 - 03 Sep 2019 00:05 #143978

by bevins

Replied by bevins on topic Bob's Plasmac Build

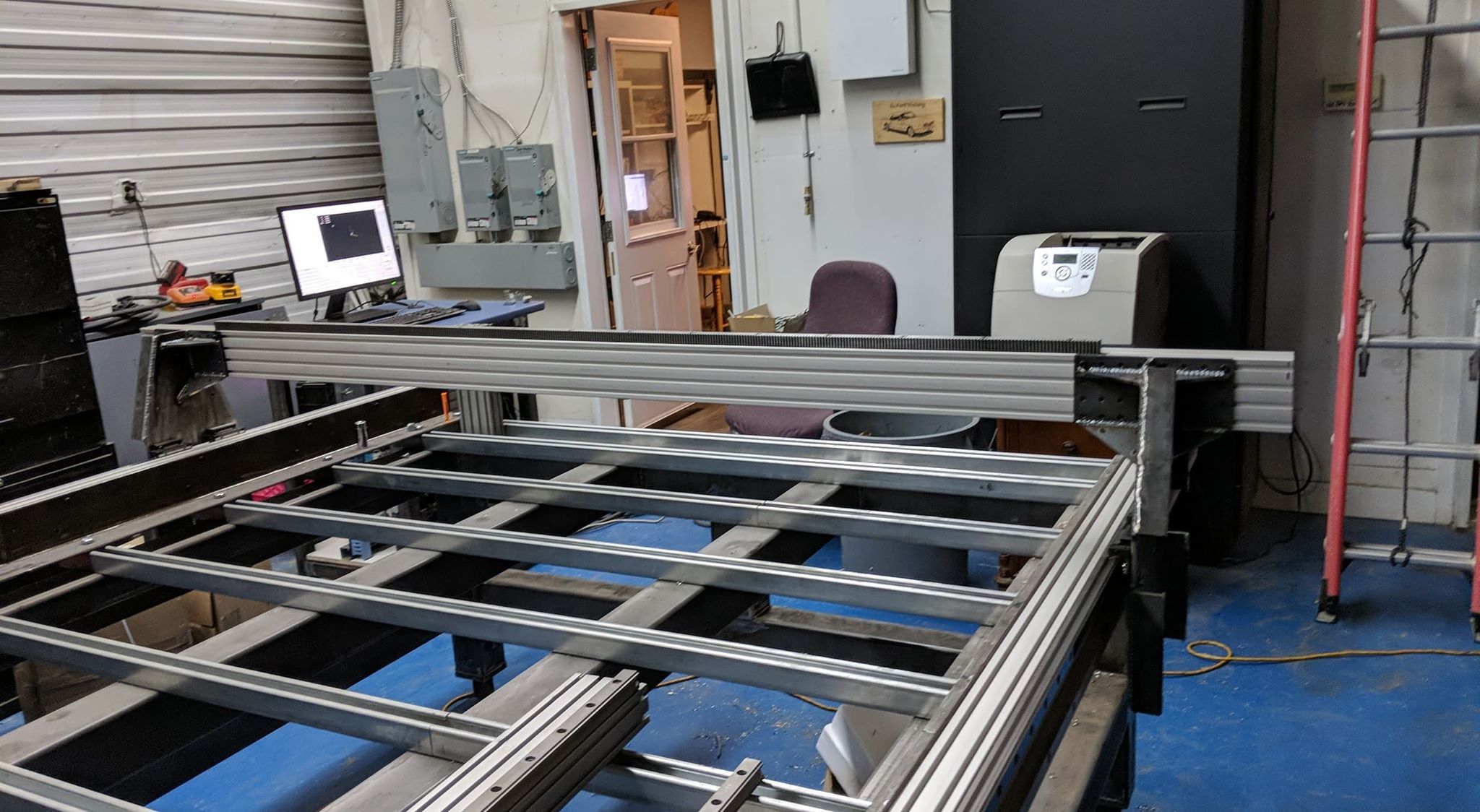

I am using 1/4" steel. I am not done as I am putting ribs on the uprights so they should be plenty rigid enough.

These servos I dont think will need reduction. It is right on the border so we will see. If it does there is planetary gearbox fits right on shaft and mount for the servos, so thats my backup plan.

The gantry will weigh less than 80 lbs so the servos should have enough torque.

These servos I dont think will need reduction. It is right on the border so we will see. If it does there is planetary gearbox fits right on shaft and mount for the servos, so thats my backup plan.

The gantry will weigh less than 80 lbs so the servos should have enough torque.

Last edit: 03 Sep 2019 00:05 by bevins.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

03 Sep 2019 03:23 - 03 Sep 2019 03:25 #144012

by islander261

Replied by islander261 on topic Bob's Plasmac Build

Bob

I am sure that you will be able to make your table work. Actually the problem is a bit more complex than just matching torques if one wishes to get optimum performance from your hardware. I thought that it was just a simple torque matching problem when I wanted to change out my stepper drives for servo drives. The corporate servo engineer pointed out the many errors in my plans. The drive problem is actually an impedance matching problem ( power transfer) and must be approached from that stand point if you want optimum performance from the smallest (least $) drives. I have attached a Kollmorgan paper on the subject if you are interested. Like I said before I am sure you will be able to make your table work.

John

I am sure that you will be able to make your table work. Actually the problem is a bit more complex than just matching torques if one wishes to get optimum performance from your hardware. I thought that it was just a simple torque matching problem when I wanted to change out my stepper drives for servo drives. The corporate servo engineer pointed out the many errors in my plans. The drive problem is actually an impedance matching problem ( power transfer) and must be approached from that stand point if you want optimum performance from the smallest (least $) drives. I have attached a Kollmorgan paper on the subject if you are interested. Like I said before I am sure you will be able to make your table work.

John

Last edit: 03 Sep 2019 03:25 by islander261.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

03 Sep 2019 10:56 #144067

by bevins

That paper makes my head hurt.

I have allotted for planetary gearboxes in my design. If direct drive is not sufficient enough, I will add gearboxes. It is a plasma so therefore I have no cutting forces so at least that is in my favor......

Replied by bevins on topic Bob's Plasmac Build

Bob

I am sure that you will be able to make your table work. Actually the problem is a bit more complex than just matching torques if one wishes to get optimum performance from your hardware. I thought that it was just a simple torque matching problem when I wanted to change out my stepper drives for servo drives. The corporate servo engineer pointed out the many errors in my plans. The drive problem is actually an impedance matching problem ( power transfer) and must be approached from that stand point if you want optimum performance from the smallest (least $) drives. I have attached a Kollmorgan paper on the subject if you are interested. Like I said before I am sure you will be able to make your table work.

John

That paper makes my head hurt.

I have allotted for planetary gearboxes in my design. If direct drive is not sufficient enough, I will add gearboxes. It is a plasma so therefore I have no cutting forces so at least that is in my favor......

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 Sep 2019 02:44 #144114

by bevins

Replied by bevins on topic Bob's Plasmac Build

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

04 Sep 2019 05:29 - 04 Sep 2019 05:30 #144123

by rodw

Replied by rodw on topic Bob's Plasmac Build

Very nice Bob. It almost looks like you know what you are doing!

Which is a lot more than I can say about me when I built mine!

Which is a lot more than I can say about me when I built mine!

Last edit: 04 Sep 2019 05:30 by rodw.

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

04 Sep 2019 07:13 #144133

by thefabricator03

I can say the same thing about when I built mine as well. I had not really seen many CNC plasma machines before and I had never used one, Lots of google image searching!!

Bob, Is this machine for a customer or yourself?

Replied by thefabricator03 on topic Bob's Plasmac Build

Which is a lot more than I can say about me when I built mine!

I can say the same thing about when I built mine as well. I had not really seen many CNC plasma machines before and I had never used one, Lots of google image searching!!

Bob, Is this machine for a customer or yourself?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

04 Sep 2019 08:22 #144139

by rodw

Replied by rodw on topic Bob's Plasmac Build

Stefan, it makes me feel better now!

It would actually be interesting to know what your gantry ends weigh with the motors mounted. They are a bit like the folded Ally ones I made and from memory they weighed about 7kg (15.4 lb) each.

I think my total gantry with ends weighed about 34 kg (75 lb) so its not that much difference to what you expect. If I did it again, I'd only use one HGR15 rail on the X axis as 2 was overkill and added more weight than what was needed.

It would actually be interesting to know what your gantry ends weigh with the motors mounted. They are a bit like the folded Ally ones I made and from memory they weighed about 7kg (15.4 lb) each.

I think my total gantry with ends weighed about 34 kg (75 lb) so its not that much difference to what you expect. If I did it again, I'd only use one HGR15 rail on the X axis as 2 was overkill and added more weight than what was needed.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 Sep 2019 11:34 #144145

by bevins

This is for a customer.

Replied by bevins on topic Bob's Plasmac Build

Which is a lot more than I can say about me when I built mine!

I can say the same thing about when I built mine as well. I had not really seen many CNC plasma machines before and I had never used one, Lots of google image searching!!

Bob, Is this machine for a customer or yourself?

This is for a customer.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 Sep 2019 11:38 #144146

by bevins

I think it will weigh in around 100 lbs maybe.

Still thinking on how to do the X bearings and Rack and Pinion. The bearings will have to be on two separate sides because it is only 2" X 4" alu extrusion. Rack and pinion on top maybe. Not sure yet. I should have put 3" X 6", but that stuff is triple the price.

Replied by bevins on topic Bob's Plasmac Build

Stefan, it makes me feel better now!

It would actually be interesting to know what your gantry ends weigh with the motors mounted. They are a bit like the folded Ally ones I made and from memory they weighed about 7kg (15.4 lb) each.

I think my total gantry with ends weighed about 34 kg (75 lb) so its not that much difference to what you expect. If I did it again, I'd only use one HGR15 rail on the X axis as 2 was overkill and added more weight than what was needed.

I think it will weigh in around 100 lbs maybe.

Still thinking on how to do the X bearings and Rack and Pinion. The bearings will have to be on two separate sides because it is only 2" X 4" alu extrusion. Rack and pinion on top maybe. Not sure yet. I should have put 3" X 6", but that stuff is triple the price.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

04 Sep 2019 13:10 #144150

by rodw

Replied by rodw on topic Bob's Plasmac Build

Still thinking on how to do the X bearings and Rack and Pinion. The bearings will have to be on two separate sides because it is only 2" X 4" alu extrusion. Rack and pinion on top maybe. Not sure yet. I should have put 3" X 6", but that stuff is triple the price.

I know the feeling. It was all a bit of a puzzle. I Went through so many iterations.

I got mine to fit on an 80mm x 40mm extrusion so you have plenty of room. When you say bearings, you mean linear bearings and rails? If you look at the radial torque specs of the HGR rails, you only need one rail (even for HGR15...) Provided you are not wanting to use it as a router!... Clive's looked nice with a rear mounted motor...

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 2.267 seconds