Schaublin 125-CNC retrofit.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

09 Mar 2021 18:57 #201584

by db1981

Replied by db1981 on topic Schaublin 125-CNC retrofit.

Hi,

did the original controll CSS with the radiator. What is the ratio range from the radiator?

If they have done CSS with it, you should also be able to do it.

I'm not realy shure at the moment, but i think the board is designed for fast switching and small step positioning. For switching the motor phases they used Triacs, so the relais D5 has only to switch the gate current of the triac.

so you have to control that the direction contactor d6 is only toogled while the triacs are not enaged. If you programm this with an 2Point Control loop and the right control cycle time and right hysteris this could work very well.

did the original controll CSS with the radiator. What is the ratio range from the radiator?

If they have done CSS with it, you should also be able to do it.

I'm not realy shure at the moment, but i think the board is designed for fast switching and small step positioning. For switching the motor phases they used Triacs, so the relais D5 has only to switch the gate current of the triac.

so you have to control that the direction contactor d6 is only toogled while the triacs are not enaged. If you programm this with an 2Point Control loop and the right control cycle time and right hysteris this could work very well.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

09 Mar 2021 19:36 #201589

by J Green

Replied by J Green on topic Schaublin 125-CNC retrofit.

Single phase 48volt secondary control transformers should be easy to find . Should even be able to get center taped 24 volt and make up a 24 - 12 - 5 volt DC linear power supply .

Do you know what the 48 volt AC contactor coil amp/current draw is an what is the coil resistance value?

Can't the existing Contactor s coils be replaced with a 220 Volt AC (use a SSR to activate it - them) or 24 VDC coil ? Could you add re turns to the existing coil ?

That poor maligned 3 phase xfmr

Think about powering it with your VFD and direct connect the spindle motor to the Xfmr to see if there is useful electrical noise reduction .

The pneumatic bay

What if the Air filter - pressure regulator -pressure gage are moved to a shop wall ?

Even better make up a remote power-control cabinet having storage shelves on it's upper area , along the lines of Deckel CNC Mills ?

Do you know what the 48 volt AC contactor coil amp/current draw is an what is the coil resistance value?

Can't the existing Contactor s coils be replaced with a 220 Volt AC (use a SSR to activate it - them) or 24 VDC coil ? Could you add re turns to the existing coil ?

That poor maligned 3 phase xfmr

Think about powering it with your VFD and direct connect the spindle motor to the Xfmr to see if there is useful electrical noise reduction .

The pneumatic bay

What if the Air filter - pressure regulator -pressure gage are moved to a shop wall ?

Even better make up a remote power-control cabinet having storage shelves on it's upper area , along the lines of Deckel CNC Mills ?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

10 Mar 2021 18:48 #201682

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Really appreciate the inputs guys. My head is still swimming with options, but that is good.

I dont know whether the original controller altered motor speed to maintain CSS during the cut, or just set the CSS for the start of the cut. The manual is not clear on that. Thanks for looking at the variator speed control board. I dont know enough about electronics, so you imput is really helpful.

I calculate that the variator provides about a 5:1 speed range. Higest speed 3000 RPM 4 Pole, 1:1 direct drive, max variator verses slowest speed 48RPM with 6 Pole, 1:6,5 back gear and minimum variator

Getting a 48VAC transformer is not so much the problem, it is that I dont was a whole bunch of them. As it is I will need 24VDC, 12VDC, 5VDC but an get them in DIN rail format and mount them on the back of the door.

Thos conntactors date from the late 1970's. I doubt I can get replacement25VDC coils, and also dont really want the space consumed by 5 of them.

I am planning to put the air filter, main valve out of the cabinet on the back of the machine.

Moving more out to a separate cabinet just moves the space problem. I want to reduce the foot print, not just move it around.

Mark

I dont know whether the original controller altered motor speed to maintain CSS during the cut, or just set the CSS for the start of the cut. The manual is not clear on that. Thanks for looking at the variator speed control board. I dont know enough about electronics, so you imput is really helpful.

I calculate that the variator provides about a 5:1 speed range. Higest speed 3000 RPM 4 Pole, 1:1 direct drive, max variator verses slowest speed 48RPM with 6 Pole, 1:6,5 back gear and minimum variator

Getting a 48VAC transformer is not so much the problem, it is that I dont was a whole bunch of them. As it is I will need 24VDC, 12VDC, 5VDC but an get them in DIN rail format and mount them on the back of the door.

Thos conntactors date from the late 1970's. I doubt I can get replacement25VDC coils, and also dont really want the space consumed by 5 of them.

I am planning to put the air filter, main valve out of the cabinet on the back of the machine.

Moving more out to a separate cabinet just moves the space problem. I want to reduce the foot print, not just move it around.

Mark

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

10 Mar 2021 19:57 #201692

by db1981

Replied by db1981 on topic Schaublin 125-CNC retrofit.

only an info:

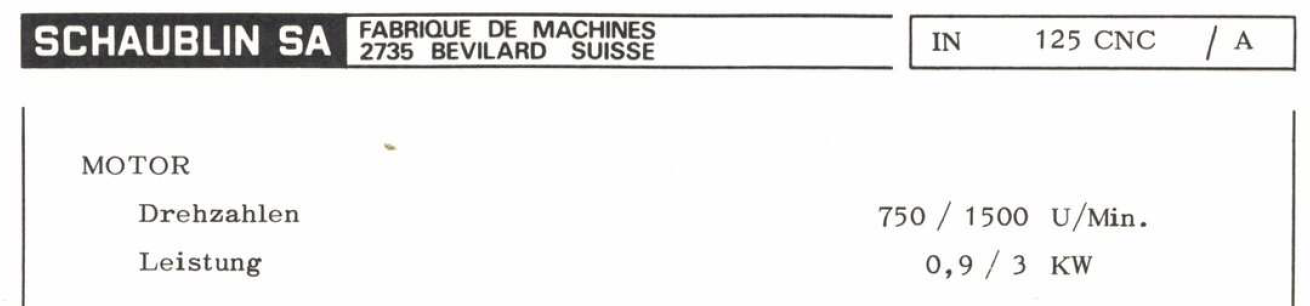

this seems to be an 2/4 pol motor instead as thought an 4/6 pol motor:

2 pol 3000 rpm

4 pol 1500 rpm

6 pol 1000 rpm

this seems to be an 2/4 pol motor instead as thought an 4/6 pol motor:

2 pol 3000 rpm

4 pol 1500 rpm

6 pol 1000 rpm

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

10 Mar 2021 20:18 #201697

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Attachments:

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

10 Mar 2021 20:59 #201712

by J Green

Replied by J Green on topic Schaublin 125-CNC retrofit.

Bummer -- guess the foot print sizing thing means a bar feeder and chip conveyor are not going to happen .

See that ZincBoy has posted the SSR Bd. schematic an parts listed --#201613

One 48 volt centrer tap Xfmr could power the conntactors an also the 24 -12 and 5 volt DC power.

See that ZincBoy has posted the SSR Bd. schematic an parts listed --#201613

One 48 volt centrer tap Xfmr could power the conntactors an also the 24 -12 and 5 volt DC power.

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

10 Mar 2021 23:15 #201751

by db1981

Replied by db1981 on topic Schaublin 125-CNC retrofit.

hmm,

where is 1:2 transmission to get the 3000 upm at the spindle ?

where is 1:2 transmission to get the 3000 upm at the spindle ?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

11 Mar 2021 00:21 #201767

by andypugh

On my mill I get the voltages < 24 from a bunch of DC-DC converters.

This style, with digital display of input and output voltages:

www.ebay.co.uk/itm/153696915953

Currently three of them, 12V for the PC, 5V for the Mesa cards and 4.2V for the Ikea LED lights.

Replied by andypugh on topic Schaublin 125-CNC retrofit.

Getting a 48VAC transformer is not so much the problem, it is that I dont was a whole bunch of them. As it is I will need 24VDC, 12VDC, 5VDC but an get them in DIN rail format and mount them on the back of the door.

On my mill I get the voltages < 24 from a bunch of DC-DC converters.

This style, with digital display of input and output voltages:

www.ebay.co.uk/itm/153696915953

Currently three of them, 12V for the PC, 5V for the Mesa cards and 4.2V for the Ikea LED lights.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

11 Mar 2021 08:07 #201780

by RotarySMP

Electrically switching from 8 pole to 4 poles on the motor.

Mark

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

hmm,

where is 1:2 transmission to get the 3000 upm at the spindle ?

Electrically switching from 8 pole to 4 poles on the motor.

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

11 Mar 2021 08:08 - 11 Mar 2021 08:11 #201781

by RotarySMP

Thanks, you have posted those before. Look pretty good, and I will consider them, altough Din Rail transformers are now cheap as well, and I wouldn't have to muck around designing and printing a housing.

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

On my mill I get the voltages < 24 from a bunch of DC-DC converters.

This style, with digital display of input and output voltages:

www.ebay.co.uk/itm/153696915953

Currently three of them, 12V for the PC, 5V for the Mesa cards and 4.2V for the Ikea LED lights.

Thanks, you have posted those before. Look pretty good, and I will consider them, altough Din Rail transformers are now cheap as well, and I wouldn't have to muck around designing and printing a housing.

Last edit: 11 Mar 2021 08:11 by RotarySMP.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.271 seconds