Schaublin 125-CNC retrofit.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 137

15 Dec 2022 00:11 #259522

by smc.collins

looks like a motor with a speed tracking issue, first Lcnc is driving up the Vout to get the requested speed, then the drive is responding with it's own loop by the looks of things. That sinusoid is a motor that is probably overdamped and does not have sufficient drive current.

So the damping is attempting to recover the overshoot after Lcnc see's the relative velocity is low and it drives up gain, then the sinusoid is probably lack of motor TQ to hold the required speed and it just keeps oscillating. The reason I wanted you to turn down the Lcnc pid loop control was to get exactly this kind of feedback.

So, what I would do

Turn up max motor current, turn down dampening. The ringing is indicative of excessive holding TQ in the motor driver. If you put your hand on it, can you feel it ringing when it is sitting still ? if so,

p04-03 &p04-04 internal clamp setup , and internal clamp amount, afaict these are your COMPensation values for zero request holding, reducing p04-04 should reduce the ringing.

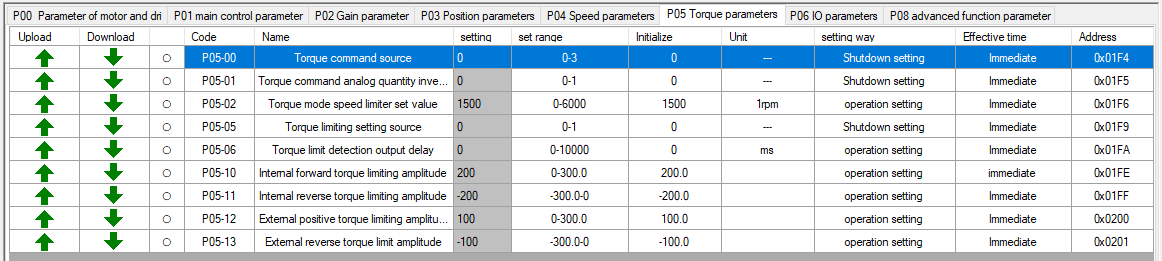

. p05-10 & p05-11 these are the internal TQ limits, what are these settings ?

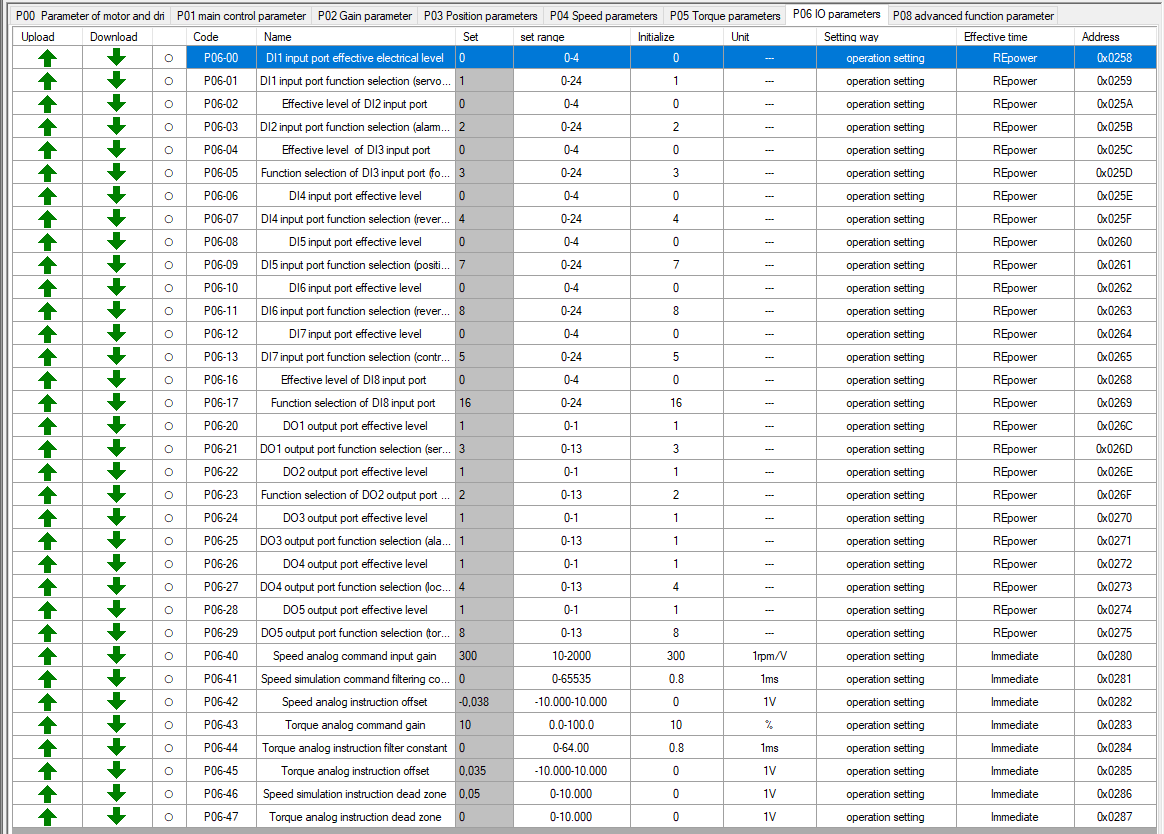

p06-40 is the input gain value, this will matter once we know the values for the motor max speed, and the lead screw pitch. Given that you have been able to use the lathe and it seems to be making parts that are the correct size, it seems like the encoder counts are correct for the pitch.

Do however need to calculate you Velocity command loop maximum speed to get the gain scaling correct for the drive and Lcnc

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

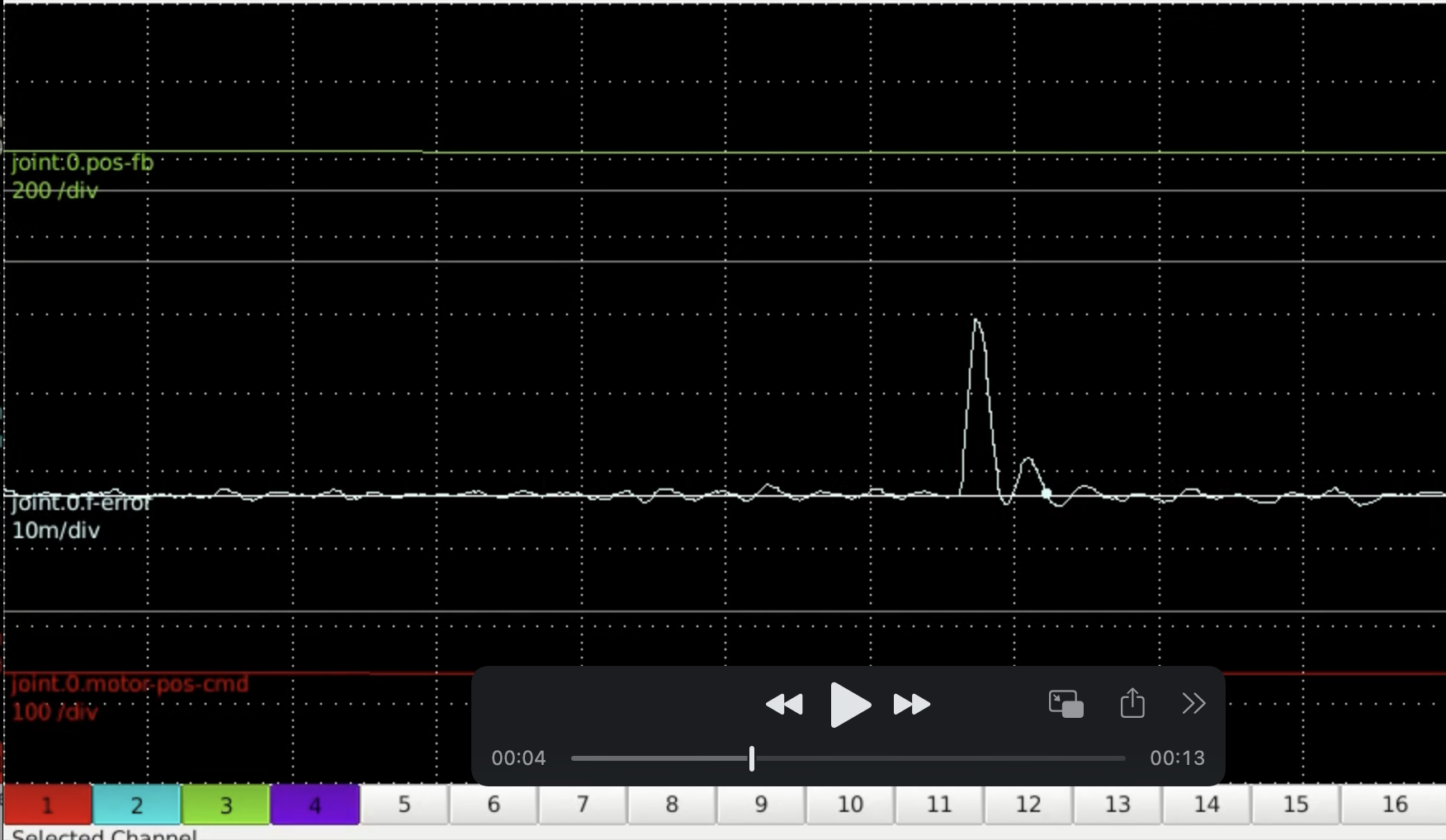

RotarySMP post=259493 userid=2917Here is a zoomed in version of the plot at a change in directions...

looks like a motor with a speed tracking issue, first Lcnc is driving up the Vout to get the requested speed, then the drive is responding with it's own loop by the looks of things. That sinusoid is a motor that is probably overdamped and does not have sufficient drive current.

So the damping is attempting to recover the overshoot after Lcnc see's the relative velocity is low and it drives up gain, then the sinusoid is probably lack of motor TQ to hold the required speed and it just keeps oscillating. The reason I wanted you to turn down the Lcnc pid loop control was to get exactly this kind of feedback.

So, what I would do

Turn up max motor current, turn down dampening. The ringing is indicative of excessive holding TQ in the motor driver. If you put your hand on it, can you feel it ringing when it is sitting still ? if so,

p04-03 &p04-04 internal clamp setup , and internal clamp amount, afaict these are your COMPensation values for zero request holding, reducing p04-04 should reduce the ringing.

. p05-10 & p05-11 these are the internal TQ limits, what are these settings ?

p06-40 is the input gain value, this will matter once we know the values for the motor max speed, and the lead screw pitch. Given that you have been able to use the lathe and it seems to be making parts that are the correct size, it seems like the encoder counts are correct for the pitch.

Do however need to calculate you Velocity command loop maximum speed to get the gain scaling correct for the drive and Lcnc

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 137

15 Dec 2022 00:12 - 15 Dec 2022 00:24 #259523

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

P06-40 Input gain of speed command 10-2000 500 1rpm/V Immediate

whats this value currently ?

here's how to unlock the drive parameters afaict

11 AF_unL Relieve lock 1.Press operation panel of the M button, switch to the auxiliary mode AF_XXX, the Up/Down buttons to AF_unL, press the ENT key. Then edit the lock level. 0:All parameter lock, 1:Lock P00-XX parameter, 2:Donot lock parameter. 2. Press M button to exit

page 51 of the PDF

whats this value currently ?

here's how to unlock the drive parameters afaict

11 AF_unL Relieve lock 1.Press operation panel of the M button, switch to the auxiliary mode AF_XXX, the Up/Down buttons to AF_unL, press the ENT key. Then edit the lock level. 0:All parameter lock, 1:Lock P00-XX parameter, 2:Donot lock parameter. 2. Press M button to exit

page 51 of the PDF

Last edit: 15 Dec 2022 00:24 by smc.collins.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2022 20:02 - 15 Dec 2022 20:16 #259574

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Duplicate

Last edit: 15 Dec 2022 20:16 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2022 20:16 #259576

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

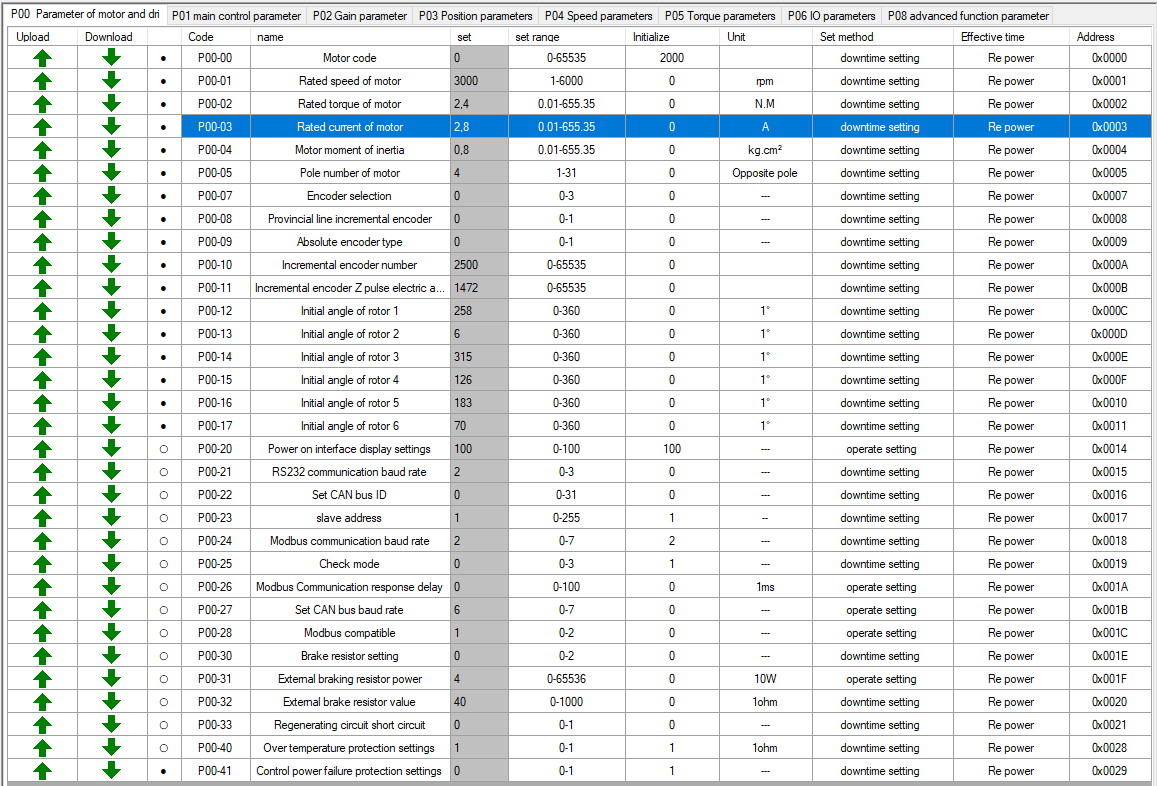

There must be an EPROM or something in the motor, as the driver interogates the motor and sets all the main parameters like Enc count, Amps, moment of inertia etc automatically. There is a slight discrepancy between the automatically set rated torque of 2.8A, and nameplate 3A.First thing to check the page 04 with speed parameters, those must be correct before anything else.

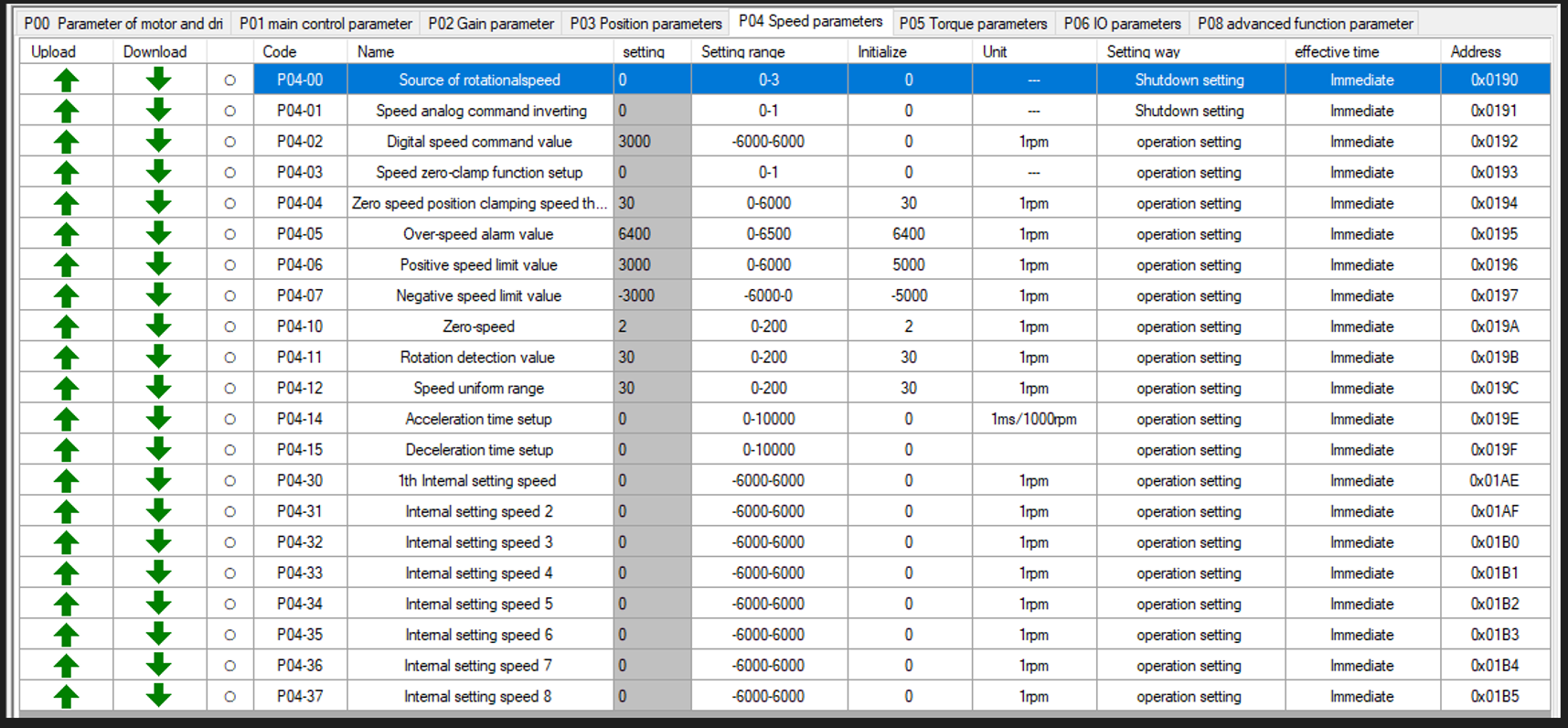

Type P00-07 and line numbers P00-10 for the encoder, P04-02 should be set at 10, and maximum motor speed P04-06 and P04-07.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2022 20:41 - 15 Dec 2022 20:46 #259579

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

"The reason I wanted you to turn down the Lcnc pid loop control was to get exactly this kind of feedback."

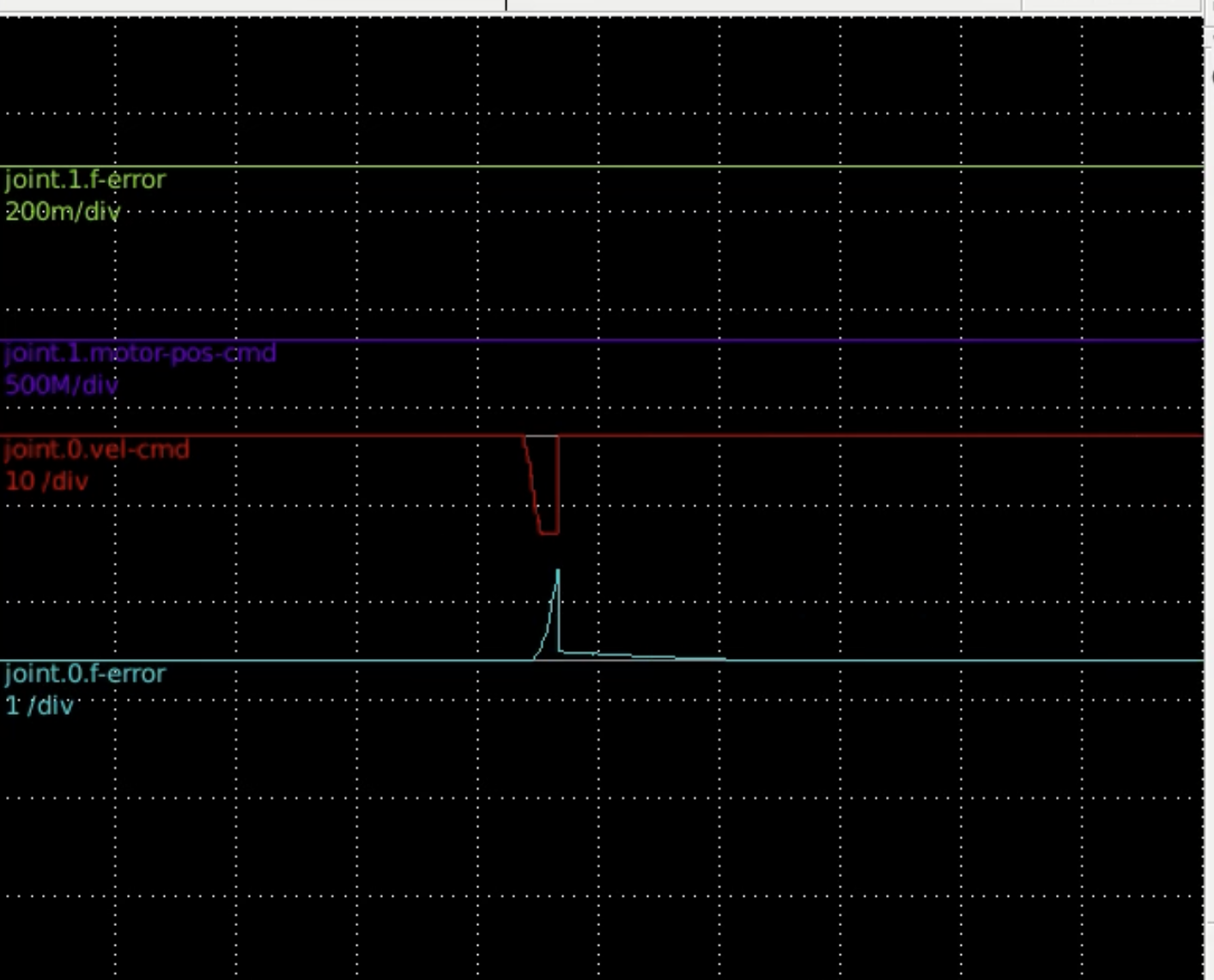

Sorry, so I should reset LinuxCNC down to P0 FF1, and try and capture the V_Out plot as the motor jerks on a motion command, before the joint errors out?This is it here:

"Turn up max motor current"

I went through the motor parameters. There is no driver variable to set Max current. Only the rated current. Currently 2.8A, I could up that to 3A, as it says on the motor nameplate.Here are the P00 motor parameters as read into the driver:

Here are the P04 parameters as set by the autotuning.

Sorry, so I should reset LinuxCNC down to P0 FF1, and try and capture the V_Out plot as the motor jerks on a motion command, before the joint errors out?This is it here:

"Turn up max motor current"

I went through the motor parameters. There is no driver variable to set Max current. Only the rated current. Currently 2.8A, I could up that to 3A, as it says on the motor nameplate.Here are the P00 motor parameters as read into the driver:

Here are the P04 parameters as set by the autotuning.

Attachments:

Last edit: 15 Dec 2022 20:46 by RotarySMP.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 137

15 Dec 2022 20:43 - 15 Dec 2022 20:45 #259580

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

the drives might be able to measure field current winding impedance and inductance and know what motors are attached.

that voltage trace looks exactly like my tuning experience when my gain was to low for my requested velocity.

I'll look tonight

that voltage trace looks exactly like my tuning experience when my gain was to low for my requested velocity.

I'll look tonight

Last edit: 15 Dec 2022 20:45 by smc.collins.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2022 20:47 #259581

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

I had to edit my answers as I am juggling video files on the LCNC computor, screen grabing on the MBP, and also on the Zbook.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2022 20:51 #259582

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

"The ringing is indicative of excessive holding TQ in the motor driver. If you put your hand on it, can you feel it ringing when it is sitting still ?"

No, I feel nothing, also the Osci plot when no motion is commanded is completely flat.

No, I feel nothing, also the Osci plot when no motion is commanded is completely flat.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2022 21:01 #259583

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

". p05-10 & p05-11 these are the internal TQ limits, what are these settings ?"

"p06-40 is the input gain value, this will matter once we know the values for the motor max speed, and the lead screw pitch. Given that you have been able to use the lathe and it seems to be making parts that are the correct size, it seems like the encoder counts are correct for the pitch."

Motormaxspeed= 3000rpm.

Lead screw pitch is 4mm in X. Everything here has been the X axis so far. Belt reduction is 2:1.

(Leadscrew pitch is 6mm in Z, Reduction 3:1 )

Correct, I have the encoder counts set correctly for those balls screws , reductions and quadrature. On both axis it is 5000 counts/mm

"p06-40 is the input gain value, this will matter once we know the values for the motor max speed, and the lead screw pitch. Given that you have been able to use the lathe and it seems to be making parts that are the correct size, it seems like the encoder counts are correct for the pitch."

Motormaxspeed= 3000rpm.

Lead screw pitch is 4mm in X. Everything here has been the X axis so far. Belt reduction is 2:1.

(Leadscrew pitch is 6mm in Z, Reduction 3:1 )

Correct, I have the encoder counts set correctly for those balls screws , reductions and quadrature. On both axis it is 5000 counts/mm

Attachments:

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 137

15 Dec 2022 23:47 - 16 Dec 2022 04:08 #259597

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

sorry Mark, was typing on my phone. so if motor speed is 3000rpm and reduced 2:1 motor speed at the lead screw is a whopping 1500rpm , so 1500/4 is 375mm minute, or .35m/min or 5.8mm/sec

Try this first, turn your max motor speed upto 6000rpm, on both axis.

see if that resolves or improves the makeup gain situation. recalculate your velocity's from leadscrew pitch enter those values in your ini file

Try this first, turn your max motor speed upto 6000rpm, on both axis.

see if that resolves or improves the makeup gain situation. recalculate your velocity's from leadscrew pitch enter those values in your ini file

Last edit: 16 Dec 2022 04:08 by smc.collins.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.205 seconds